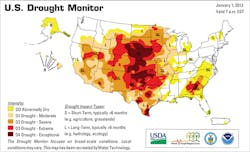

The value of our water resources is signified not just by our reliance on water for drinking, but industrial and agricultural thirsts as well. We have limited freshwater on the planet with persistent zones of chronic water scarcity, particularly in the Middle East and Africa. Even in the U.S., the record-breaking 2012 North American Drought inflicted moderate-to-exceptional water scarcity in more than 60 percent of the continental U.S. By August 2012, the drought led to the classification of 1,584 counties across 32 states — over half the counties in the country — as primary disaster areas. According to the United States Department of Agriculture (USDA), nearly 80 percent of agricultural land in the U.S. remains in a state of drought today.

Against this backdrop, we continue to discover the presence of pollutants in our water supplies, leading to the quarantine of aquifers and the closure of valuable wells. One such pollutant, 1,4-Dioxane, comes into our water resources primarily from industrial use as a solvent stabilizer. Solvents used in various cleaning and degreasing applications tend to react or break down, which is why solvent stabilizers, such as 1,4-Dioxane are added. In fact, 90 percent of the 1,4-Dioxane production in the U.S. in 1985 was used as a stabilizer for chlorinated solvents, such as trichloroethane (TCA) and trichloroethylene (TCE). Industries known for historically using chlorinated solvents with 1,4-Dioxane include the textile, chemical manufacturing, plastics, electronics and metal industries. Predictably 1,4-Dioxane often correlates with TCE or other chlorinated solvent environmental contamination.

1,4-dioxane is also detected in consumer products, such as shampoos, soaps, waxes and lotions, as a result of contamination of ethoxylated compounds, such as sodium laureth sulfate. Given that 1,4-Dixoane readily permeates the skin, cosmetics manufacturing companies have begun employing methods to reduce 1,4-Dioxane formation and eliminate the compound from industrial process waters. Wastewater influent receiving product residuals contaminated with 1,4-Dioxane are poorly equipped to remove or degrade the recalcitrant compound, leading to further release in the environment.

Sources and issues of 1,4-Dioxane

In groundwater, 1,4-Dioxane has been found to be extraordinarily soluble and resistant to biodegradation by indigenous microorganisms. The chemical properties of this compound demonstrate why typical groundwater and municipal wastewater treatment facilities cannot reduce its concentration. 1,4-Dioxane’s hydrophilicity combined with a low Henry’s Law constant mean that typical filtration, volatilization or adsorption treatment technologies have limited utility. In groundwater plumes, 1,4-Dioxane has been found to travel further than co-contaminants TCE and toluene due to differences in attenuation by sorption and biodegradation. Thousands of water sources around the U.S. have detected high levels of 1,4-Dioxane, particularly water reuse and recharge projects, and hundreds of treatment efforts are currently underway.

The main issue with 1,4-Dioxane is its classification as a probable human carcinogen, even at very low concentrations. Even though a Federal Maximum Contaminant Limit (MCL) has not yet been established, states such as California, Massachusetts, Florida and North Carolina have set drinking water standards for 1,4-Dioxane at low parts per billion (ppb) levels. The California Department of Public Health (CDPH), for example, has a drinking water notification level of 1 ppb and a well shutdown standard of 35 ppb. An abundance of animal studies have shown that inhalation and ingestion of 1,4-Dioxane readily forms nasal cavity and liver carcinomas along with neurotoxic effects. Treating 1,4-Dioxane is a priority not just for drinking water purposes, but for ensuring the availability of groundwater and surface water resources for agricultural and industrial operations as well.

The treatment of 1,4-Dioxane using most conventional technologies has not been effective. Carbon absorption, activated sludge, air stripping, monitored natural attenuation and bioaugmentation/biostimulation are subject to continuing research and development without sufficient advances in reducing 1,4-Dioxane concentrations to required levels. Chlorination has also been tried but found to lead to toxic chlorination byproducts, which are collectively even more toxic than 1,4-Dioxane. Distillation has been attempted but often leads to the formation of hazardous peroxides.

Finding a solution

The only technology that has shown viability in 1,4-Dioxane degradation is advanced oxidation processes (AOP) combined with UV light treatment. While direct photolysis of 1,4-Dioxane does not occur, UV light can release hydroxyl radicals from hydrogen peroxide to degrade 1,4-Dioxane into water, carbon dioxide and chloride ions. The downside of these methods is high energy and chemical costs, which tends to increase substantially in turbid water and when dealing with increasingly low concentrations of 1,4-Dioxane. Even non-turbid waters containing other pollutants, such as nitrate, can interfere with UV transmittance and raise the costs of 1,4-Dioxane treatment. For many water quality scenarios, AOP/UV will be prohibitively expensive and energy intensive compared to the cost of shutting down the well or water stream.

Originally it was thought that 1,4-dioxane could not be biodegraded. This notion was tempered by research involving isolated or purified microbial strains where aerobic degradation was achieved but only after the addition of a secondary inducing compound, such as propane or tetrahydrofuran (THF). Since many of these inducing compounds are themselves contaminants, a major need still exists to understand microbial degradation pathways and how we can achieve more effective and simplified biological treatment.

The nature of conventional above-ground bioreactors compound the problem of biologically degrading 1,4-Dioxane. Given the typically low concentrations of 1,4-Dioxane, inordinate volumes of water need to be pumped and passed through a bioreactor to achieve treatment objectives. Even then, operational problems such as the inability to retain the appropriate cells at a suitable density, the potential for incomplete degradation, clogging, biofouling and sensitivity to operating procedures and environment stresses plague conventional biological methods for 1,4-Dioxane treatment. Overcoming these issues will be critical for ensuring reliable and low cost treatment.

While research and development efforts are ongoing, water providers have little choice but to be diligent in testing for 1,4-Dioxane contamination and waiting to see which novel technologies emerge as effective treatment options. Fortunately, scientists and researchers around the world are actively working on new methods and processes for 1,4-Dioxane treatment. While much work remains to be done, there remains tremendous untapped potential to succeed in this quest. The health and safety of our valued water supplies, especially in this era of water scarcity, depends on it.

Ameen Razavi is the director of innovation research at Microvi Biotech Inc. (www.microvi.com), a biotechnology company headquartered in the San Francisco Bay Area providing innovative solutions for water and wastewater treatment, bioenergy production and biochemical synthesis. Microvi is developing a novel biocatalytic method for 1,4-Dioxane degradation in water that has zero waste, low energy and chemical requirements, a simplified process design and a small footprint. For more information, please email [email protected] or call 510-344-0668.