Managing algal blooms in industrial operations that rely on surface water

Seasonal algal blooms are becoming an increasing concern for industrial businesses that rely on freshwater for their operations, whether water is supplied by a municipal water treatment plant or drawn directly from surface water.

Due to development and climate conditions, nutrient levels push temperature and carbon dioxide levels higher, and in turn, harmful algal blooms (HABs) increase in range, intensity and length of season. These harmful algal blooms produce cyanobacteria, also known as blue-green algae, which in turn create toxins that are harmful to humans.

Some cyanobacteria that create toxins also create geosmin and 2-methylisoborneol (2-MIB), as in the case of the algal bloom in the Han River. The 319-mile Han River in South Korea flows westward from the slopes of the Taebaek Mountains through the city of Seoul to the Yellow Sea, supplying cities along its course with water for industrial and general use.

Among those industrial water users is a beverage facility that produces 45,000 bottles per day. When a seasonal algal bloom upstream produced elevated levels of taste and odor (T&O) compounds such as geosmin and 2-MIB, the owner and operator of the water treatment plant sought advanced solutions to remove these compounds and contaminants to ensure it could deliver dependable, high-quality water to its industrial and other customers.

These compounds cause earthy, musty smells detectible at very low levels — 30 ng/L for geosmin and 5 ng/L for 2-MIB. Like most cyanotoxins, these compounds are released when the algal cells die. Also like cyanotoxins, these compounds are not removed through conventional filtration. Though not technically harmful, T&O compounds raise doubts about water quality and safety.

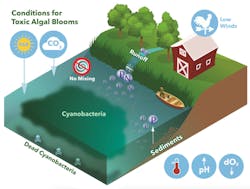

In order to manage and treat harmful algal blooms, it is important to understand how they develop. Conditions favoring harmful algal blooms occur seasonally in freshwater bodies and reservoirs and include:

• Higher CO2 levels

• Nutrient load — nitrogen and phosphorus

• Sunlight

• Temperature — warmer temperatures favor growth

• Lack of wind, turbulence

• Sediment release and biological interactions

Figure 1. Factors contributing to harmful algal blooms

Through transport of toxins released into the water, a harmful algal bloom may impact a source that is far from the actual bloom, as in the case of the Han River where the harmful algal blooms were occurring far upstream.

Management options

An industrial facility or water treatment plant has three types of management options to control harmful algal blooms:

• Source controls

• Intake modifications

• Treatment modifications

Source controls or intake modifications are critical in reducing the risk of toxins released into the raw water from the algal cells via lysing (rupturing of the algal cell wall). Once toxins are released, treatment options required to remediate them tend to be more complex.

Figure 2. Source controls

Depending upon the source water, several options might inhibit the algal growth. However, once a bloom has taken hold of a water body, it is hard to fully eliminate it, and source control methods usually require repetitive action. It is extremely difficult to remove or prevent the growth of all algal cells. Preventing the entrance of excess nutrients into the system is also challenging, especially when they may be flowing in from outside, uncontrollable sources.

For some facilities, intake modifications might keep algal cells and toxins from entering the treatment system. Vertical profiling and good data on the biochemistry of the source water is key to intelligent decision-making when looking for a new source or making modifications to an intake.

Figure 3. Intake modifications

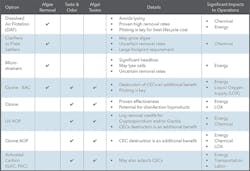

For many facilities, source controls or intake modifications are either not practical or are not capable of ensuring that no algae or toxins enter the system. For those, treatment modifications provide the only viable options.

For algae and its toxins, a two-pronged approach may be required. Treatments must deal with both algae cells and their metabolites. Most of the metabolites from algae remain inside the living cells. Therefore, if the cells can be removed intact without lysing, less of the compounds need to be removed by advanced treatment. Although once the cell dies, the cell membrane breaks down and the compounds are released into the water. Since some cells have died in every bloom, these compounds will be present regardless of how careful the intact cells are removed.

"Once released into the water, the toxins and T&O compounds are difficult to remove, requiring ozone, ozone-BAC, AOPs or adsorption with activated carbon."

The goal of removing the intact cells is to minimize the concentrations of toxins. Once released into the water, the toxins and T&O compounds are difficult to remove, requiring ozone, ozone-biologically activated carbon (BAC), advanced oxidation processes (AOPs) or adsorption with activated carbon. These processes require ongoing life cycle costs (LCC), so it is often more economical to first remove intact cells in order to lower concentrations in the water and reduce the scope of treatment. Processes for cell removal, particularly dissolved air flotation (DAF), may have lower LCC than destruction or adsorption of the toxins and T&O compounds. Treatment modifications should be viewed in this two-pronged approach of cell removal and treatment.

Cell removal methods: When evaluating removal options, keep in mind the algae’s natural buoyancy. This makes removal through settling processes more difficult, requiring more chemical to force the algae to settle. Also, with algae’s sticky texture, it can quickly blind strainers and filters. Because of these properties, DAF is often the best alternative because it takes advantage of the buoyancy and can remove the algae without lysing or blinding.

Compound removal methods: In most cases, removal of the algae alone will not remove the toxins or T&O compounds; all of which are difficult to break down with standard disinfection. Additional treatment is usually needed. These treatments use ozone, AOPs (using hydrogen peroxide and either ozone or ultraviolet light), ozone-BAC, or adsorption using granular activated carbon (GAC) or powdered activated carbon (PAC). Clearly, keeping these compounds to a minimum by removing as much intact algae as possible reduces the costs of these treatments.

Every source water and the exact capital and operating costs will also be unique, based on the source water quality and other treatment objectives. Many of the treatments to adsorb or destroy toxins and T&O compounds are also effective for contaminants of emerging concern (CECs). The overall analysis should consider future treatment objectives and anticipate future regulation to the extent possible. Keep in mind that HAB impacts can be seasonal in nature, so a complete analysis would consider turndown capabilities and the associated savings for an accurate LCC.

Figure 4. Treatment modifications

A comprehensive evaluation should consider all these factors and develop a low to high LCC ranking for a specific facility based on the range of treatment options and objectives.

Monitoring options

Recent advances in monitoring technology can help facilities stay ahead of algal blooms. By knowing if the conditions are right and if the algae in the surface water supply is indeed cyanobacteria, facilities can take steps to mitigate the impacts and minimize liability — at a minimal cost by not treating when it’s not necessary or, if there is a bloom, possibly using technology to locate and access raw water with lower concentrations of algae.

The best monitoring strategy is twofold: in the water and out. Out of the water, monitor for conditions that favor algal blooms and cyanobacteria. High temperatures favor cyanobacteria; barometric pressure affects dissolved gases at the water’s surface. Wind direction and speed can affect migration patterns of blooms. And in particular, the wavelength of sunlight — photosynthetically active radiation (PAR) — is the energy source of blue-green algae.

In-water monitoring can help spot conditions that either favor algal formation or might be indicative of the beginning of a bloom. Phytocyanins are found specifically in blue-green algae, for instance, and pH levels generally rise due to high growth.

Timing is critical, so in-situ monitoring is essential to know what is happening in real time. One vital link is determining if an algal bloom is indeed blue-green algae. Due to advances in sensor technology, which can measure fluorescence to distinguish between green and blue-green algae, this determination can now be made in real time. Real-time identification allows a proactive response to a bloom, rather than waiting days for test results.

The solution for the Han River harmful algal blooms was to invest in additional water treatment facilities that included a Xylem AOP system that combined ozone and hydrogen peroxide to remove the compounds and other contaminants in combination with activated carbon filtration.

Ozone is produced by three ozone generators, with a total capacity of 51 kilograms ozone per hour, fed with liquid oxygen. The ozone feed is combined with hydrogen peroxide to form hydroxyl radicals — highly effective oxidizing agents and the key to T&O destruction. An underground hydrogen peroxide storage and delivery system efficiently mixes the ozone and hydrogen peroxide via two ozone injection lines. Following injection, the water flows through two separate concrete contact tanks for reaction and degassing.

Conclusion

Due to many factors, there is no one-size-fits-all approach for dealing with harmful algal blooms. Awareness and preparedness can help ensure an industrial facility will be ready when and if harmful algal blooms come calling.

Steve Green is the Water Utilities Business Development Manager for Xylem Inc. based in Portland, Oregon.