The potential for small system arsenic removal treatment continues to grow with every new well drilled. Up to 5 million small-system wells with arsenic levels above the maximum containment level (MCL) of 10 parts per billion (ppb) produce water in the U.S. These light commercial and residential systems with flow ranges between 5 to 300 gallons per minute (gpm) offer huge sales potential for water treatment dealers and professionals.

Because of the complexity of arsenic treatment, many installers have avoided this profitable market in the past. With new, simplified arsenic removal products, this difficulty is no longer an issue. Arsenic, a natural element found especially in areas with volcanic rock, occurs in two forms, AS(III) and AS(V). All treatment systems will remove AS(V). While a few systems will effectively remove both, the remaining systems require pretreatment to oxidize AS(III) and change it to AS(V).

Technology for residential and light commercial arsenic removal includes:

- Reverse osmosis (RO)

- Ion exchange

- Adsorption media

Reverse osmosis

RO is ideal for residential applications to supply water for drinking and cooking. With numerous systems readily available, small RO units are frequently the most cost-effective option for homeowners.

However, for larger arsenic removal systems with flow rates above 5 gpm, high capital costs may make RO systems impractical.

RO may be only partially effective and does not remove all AS(III) without pretreatment. Additionally, RO systems waste water, producing one usable, arsenic-free gallon for every four treated.

Ion exchange

Ion exchange systems are water softeners with a resin specifically designed to remove arsenic. This is a well-proven technology, usually with capital costs equal to the cost of adsorption systems, which will be discussed in the next section. However, this solution may not be as simple as it sounds. This technology has high maintenance and operation costs.

First, pretreatment with an oxidizer, such as chlorine or ozone, is required to convert AS(III) to AS(V), incurring a monthly cost for chlorine or increased electrical costs to operate an ozone generator. Then the disposal of the backwash water, which is critical, for small to medium users is expensive. The backwash cycle creates brine with high levels of arsenic and chlorides. Discharge of this brine is often regulated or banned outright by municipal sewers. The backwash water should also not be discharged into a septic tank.

Adsorption media

The most widely used media for arsenic removal from drinking water are aluminum, iron, titanium, lanthanum and zirconium metal oxides. The systems can be easily sized for residential and light commercial flow rates. With media usually supplied in a granular form or in cartridge housings, a properly designed and installed system offers the lowest maintenance and greatest reliability for small systems.

All adsorption media, by definition, form a chemical bond with arsenic. For this reason, virtually all spent media will pass a U.S. Environmental Protection Agency (EPA) Toxicity Characteristic Leaching Procedure (TCLP) and can be disposed of in a standard landfill. One exception is California in which the total arsenic content is also measured.

All media share the need for protection from iron or manganese in water. If either or both elements are found in well water, the treatment to remove them should precede the arsenic removal system. Suspended solids must also be removed prior to arsenic removal treatment.

However, not all media are equal or identical. Some are more appropriate for certain water conditions. Partnering with an expert in arsenic removal can help water treatment professionals determine the most effective media to remove the water’s contaminants. Dwell time can vary greatly — from 20 seconds to 15 minutes. Designing the system to accommodate the required dwell time is essential.

Product performance levels range, too. Some media will barely achieve levels below 10 ppb. Others will take the water into the range of non-detect to 2 ppb.

"Adsorption systems are opening the door for cost-effective water use in areas of arsenic contamination that were previously untouched," said Steve Townsend, P.E., owner, SMT Consulting Engineers.

Media pH requirements

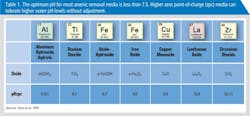

Adsorption media are affected by pH. The closer the water is to 7.0 pH, the greater the production of arsenic-free water. As shown in Table 1, the acceptable pH range of different media may become the determining factor when designing the system. Alkaline water is extremely common across the western U.S., which is also home to the vast majority of wells with naturally occurring arsenic.

Table 1. The optimum pH for most arsenic removal media is less than 7.5. Higher zero point-of-charge (zpc) media can tolerate higher water pH levels without adjustment.

Water analysis and media selection

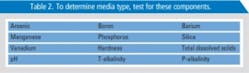

A correct water analysis must test for many elements found in water, some of which are not commonly incorporated into an average test for potable water. At a minimum, the contaminants in Table 2 must be included in the analysis.

Table 2. To determine media type, test for these components.

Competing ions — such as phosphorus, fluoride, vanadium and sulfates — can dramatically shorten media life. As with other variables, the true effect varies across media.

Silica can coat the media, which becomes a problem if the silica-hardness ratio is less than 3:1 (the hardness is three times the level of the silica).

The installer must understand that media manufacturers rate their media based on arsenic in water with a pH of 7.0. This is the most ideal condition and provides the legitimate starting point for a system design. Actual water conditions can dramatically de-rate the media’s performance. Selecting a media supplier becomes critical. Who will assist (or train) you, to best calculate the actual media’s anticipated life?

Media suppliers often talk in bed volumes — a figure that equalizes the performance of one media when compared to another given different tank sizes. Dealers and treatment professionals should not hesitate to request that bed volume be converted to the number of gallons that will be produced by the quoted system.

System design

All system designs must begin with a current, complete water analysis. The review of this information will determine system size and media longevity. Key, site-specific information must include the well pump size, well pump flow rate, size of the incoming water line, space and electrical availability, facility water demand, and other water treatment equipment in the treatment train.

Bulk media require a minimum amount of contact time. Therefore, tank dimensions are critical. In addition, many media require periodic backwash. If so, provisions must be made to supply adequate water and a backwash pump.

All systems should have a quality totalizing flow meter. The flow meter is an essential component to ensure media are changed prior to arsenic breakthrough. Installers should expect their suppliers to review the analysis and make specific design recommendations to provide a complete system.

Installation and service

Arsenic removal system installation should be within the capability of any experienced installer. The possible addition of pretreatment, solids filtration and pH adjustment are similar components used in other water treatment systems.

For service, a regularly scheduled monitoring program should include an annual water panel analysis. Without periodic testing of the raw water and treated water, the ongoing effectiveness of the arsenic removal system will be unknown.

A water treatment technician should be prepared with the system information, test tools and a checklist for each customer monitoring visit. A field test kit is essential. Most field test kits will provide a result within 15 minutes. Tests are available in different ranges. For initial well water testing, a kit that ranges up to 100 ppb is recommended. For ongoing monitoring of an installed system, a kit with a range of 0 to 10 ppb is the best choice.

Once the life expectancy of the media is expressed in gallons (rather than bed volumes), the installer has the two key elements for the proper maintenance of the system. The goal of monitoring is to determine when to change the media. Arsenic media are not inexpensive, so end users want to squeeze the last gallon out of the system before a media change.

Cartridge-based arsenic removal media are often ideal for small- to medium-size residential and commercial systems. No special equipment, such as vacuum trucks, is needed to remove spent media. The installer or end user can readily remove the spent cartridges and replace them with new ones. A regular exchange based on water quality can be scheduled by the installer/dealer to generate a continued, long-term revenue stream.

Market potential

"Arsenic treatment is something that we have not fully pursued in the past because of multiple aspects of market size, initial and ongoing costs, system complexity, maintenance and testing requirements, and consumer perception," said Mark Scheufler, water treatment project manager with the 2M Corporation. "With the development of simple, reliable cartridge treatment systems that target the small-system market and help us meet our marketing objectives, our firm has the confidence to go forward. The dealer and consumer are responding favorably to new treatment options. In conclusion, the market for these small arsenic removal systems continues to grow — especially in the light commercial segment, which includes:

- Mobile/manufactured home parks

- RV parks

- Schools

- Restaurants

- State & national parks

- Medical facilities

- Resorts

- Casinos

- Prized livestock (purebred horse) farms

- Small communities

Water treatment professionals and dealers can take full advantage of arsenic treatment installation and after-market maintenance opportunities with training, the right products, and design and application support partnerships with media and system suppliers.

Richard Sinclair, president of Applied Process Equipment Inc. in Scottsdale, Arizona, has spent his entire career in the fluid process industry. He holds an engineering degree from Pennsylvania State University. He is a long-term member of the American Water Works Association, Water Environment Federation and AWPCA. He is also a member of the Arizona Department of Environmental Quality Onsite Wastewater Advisory Committee. Sinclair may be reached at [email protected] or 480-998-4097.

Applied Process Equipment provides water and wastewater treatment equipment to municipal, commercial and industrial customers. In addition, it manufactures ISOLUX Arsenic Removal Systems. For more information, visit www.apewater.com.