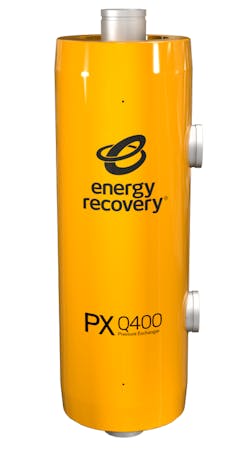

Energy Recovery launches PX Q400 pressure exchanger

(SAN LEANDRO, CA — Oct. 12, 2022 — Energy Recovery release) — Energy Recovery, a market leader in energy recovery devices (ERDs), has announced the launch of the PX Q400 Pressure Exchanger. The PX Q400 is the next evolution of Energy Recovery’s trusted and industry-leading PX Pressure Exchanger technology and will be the new flagship solution in the PX family of products.

The PX Q400 will be Energy Recovery’s highest-performing and highest-capacity PX available for seawater reverse osmosis (SWRO) desalination and industrial wastewater facilities. As the market leader of ERDs in SWRO desalination — and with 30 years of experience in the industry — the PX Q400 marks a continuation in the pursuit of making SWRO desalination more efficient and sustainable.

Key advantages of the PX Q400:

- Highest average efficiency compared to other PX technology products

- At 400 gallons per minute (gpm), it is the highest capacity PX yet, which results in 25% fewer devices compared to the PX Q300 (depending on plant size)

- Less than 3% volumetric mixing

- Offers the lowest projected life cycle cost of any ERD for SWRO desalination

“With the PX Q400, we’ve further innovated and improved upon the reliable, field-tested, and trusted PX models that preceded it,” said Rodney Clemente, Senior Vice President of Water. “The PX Q400 enhances efficiency, capacity, and value to ensure Energy Recovery remains the most trusted manufacturer of ERDs in desalination.”

Made with corrosion-proof ceramic and designed with only one moving part, the PX Q400 supports a 25-year design life with no scheduled maintenance, leading to incredibly low life cycle costs and maximum uptime.