Improvements in feed spacer geometry reduce operational costs

Reverse osmosis (RO) water treatment will play a major role in alleviating water scarcity, but to do so it requires much energy. To resolve this, improvements in feed spacer geometry can reduce overall RO system energy consumption, decreasing the operational costs of the water treatment process.

The RO process

RO is a water purification technology that removes mainly salts such as sodium chloride from water. A pressure applied by a high-pressure pump overcomes the natural osmotic pressure of a solution, allowing water to flow across a semipermeable membrane. RO membrane elements are typically offered in spiral wound configuration of three distinct layers for fluid handling. A feed spacer, or netting, acts as one of the layers and provides vital separation between the membrane surfaces to achieve superior filtration performance.

A spiral wound element refers to a membrane configuration of a flat sheet membrane, permeate channel spacer and feed channel spacer, all rolled up around a permeate collection tube. As shown in Figure 3, the membrane element structure contains the feed spacer that separates the surfaces of adjacent membrane envelopes. The feed spacer keeps the feed channel open, allowing feed water to flow inside the feed channels along the membrane element. Figure 1 shows a typical RO spiral wound element.

Figure 3. Membrane element structure

Many challenges arise in the RO membrane water treatment process. For the feed spacer component, the critical issues are:

- Pressure drop — balancing turbulence promotion against frictional losses

- Membrane damage during winding

- Biofouling and scaling during operation

- Smoothness of the netting (spacer) material

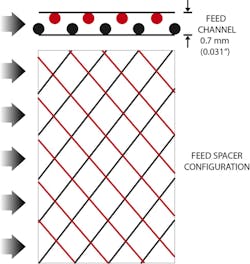

Figure 2. Feed spacer configuration

Pressure drop has a direct impact on the power consumption of the RO process. Studying the balance between turbulence promotion and frictional losses has led to the development of new, and different, structural configuration of the feed spacer used in RO element construction. This article discusses the development effort to improve pressure drop performance.

Feed spacers, pressure drop & power consumption

Feed spacers are manufactured from polymeric materials and optimized to maintain stable performance of membrane

elements in a range of feed water composition and process parameters. The configurations of a feed channel with feed spacer are shown schematically in Figure 2. The feed channel, shown in unwrapped configuration, forms a rectangular opening of typically 0.7 to 0.86 millimeters in height. The presence of spacer or netting strands in the feed channel means that the actual cross section area open to the feed flow is smaller than the geometric cross section.

The feed spacer has filaments or strands positioned in a biplanar orientation. The biplanar characteristic causes the feed stream to change flow direction as it flows above and below the subsequent filaments, promoting turbulence of the feed stream. The need for turbulence in the feed stream is related to a phenomena known as concentration polarization, which is common to all cross-flow membrane processes. As the feedwater and dissolved salts flow parallel to the membrane surface, only a fraction of the feedwater passes through the membrane as permeate, leaving the dissolved ions to accumulate at the membrane surface and limiting membrane performance. The feed spacer-induced turbulence reduces the extent of concentrate polarization. However, the induced turbulence increases friction in the feed channel, which is translated into pressure drop of the feed stream between the element feed and exit points.

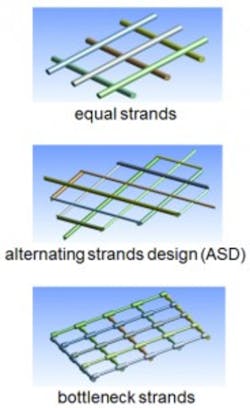

Figure 4. Feed spacers

After much experimentation and hydraulic modelling, the configuration of feed spacers for RO applications has evolved into a biplanar net with square or rhomboid openings, commonly known as diamond netting. The spacer is positioned in the feed channel with net filaments at an angle of about 45° to the direction of the feed flow (see Figure 3). This configuration results in acceptable trade-off of sufficient turbulence and mixing the feed stream without excessive pressure drop.

It is well known that very clean feedwater with low concentration of suspended matter is required for stable operation of RO membrane units. If the feed channel is clean without particles that could block the feed water flow, the pressure drop across a single RO element is about 0.1 to 0.2 bar. In RO systems, membrane elements operate while enclosed in a pressure vessel. A single pressure vessel usually contains six to eight membrane elements operating in series. Therefore, the combined pressure drop along a pressure vessel is from 0.6 to 1.5 bar. In brackish applications, the RO systems are mainly configured as two-stage systems, such that the combined pressure drop will be frequently in the range of 1.5 to 3 bar.

The friction losses (or pressure drop) in the membrane element feed channels contribute to overall energy usage of the RO unit. Each bar of pressure drop is equivalent to additional energy usage of about 0.025 kilowatt-hour per cubic meter of product water produced, based on the typical efficiencies of feed pumps and motors. Accordingly, the configuration of the feed spacer must provide sufficient turbulence and mixing in the area adjacent to the membrane surface without significant increase of pressure drop in the feed channel.

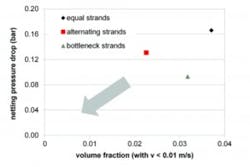

Figure 5. The results of calculations of basic feeder spacer geometries

Optimizing feed spacer geometry using alternating strand design

A project was initiated to develop a novel feed spacer configuration addressing the outlined challenges. In a first step, basic feed spacer geometries were evaluated, using 3-D printed samples and detailed computational fluid dynamics (CFD) calculations toward decreasing pressure drop and minimized low flow areas. Feed spacers using equal strands, alternating strands and bottleneck type strands (see Figure 4) were evaluated. The basic results of these calculations, summarized in Figure 5, show that a structure of alternating thick-thin strand type feed spacers are well balanced for pressure drop while minimizing areas of low feed water velocity.

As a next step, a number of different feed spacer types that were produced using large scale netting production technology were tested in a flow cell measurement program. The feed spacer samples were installed in a special flow cell1 and evaluated for pressure drop performance using different conditions, such as feed flow, time or fouling conditions. A selection of tested feed spacer geometries, along with corresponding pressure drop results, are shown in Figure 6 at a given flow rate of 20 liters per hour. This research confirmed the enhanced pressure drop performance of feed spacer material based on the new alternating (thick-thin) strand design (ASD) technology.

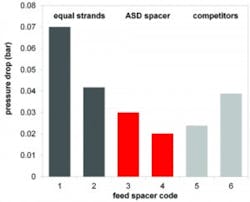

Figure 6. Feed space results

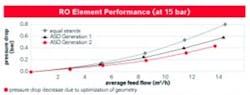

The RO elements constructed with the alternating strand geometry achieved a lower pressure drop than other commercially available feed spacers. The pressure drop data presented in Figure 7 suggest a reduction of approximately 0.05 to 0.15 bar per element at nominal flow rates. This translates to approximately a 5 percent reduction in specific energy consumption. In addition, the new ASD type spacer shows a finely tuned flow

pattern that results in reduced low flow areas expected to reduce biofouling tendency. This reduced biofouling tendency can be seen as an improvement toward increased membrane life and lower cleaning frequency of RO membrane elements.

Conclusion

Feed spacer structural geometry has an important impact on pressure drop and other critical performance issues. The ASD has been shown to reduce pressure drop more than common spacer structural configurations in other commercially available spacers. The savings in power consumption can be estimated from the data at approximately 0.1 bar per RO element and approximately 5 percent reduction in specific energy consumption. The ASD feed spacer offers other interesting potential process improvements, such as minimization of low flow areas to reduce biomass accumulation.

Figure 7. Pressure drop data

Reference

Araújo, P.; Kruithof, J.; Loosdrecht, M. V. & Vrouwenvelder, J. "MFS membrane fouling simulator: The potential of standard and modified feed spacers for biofouling control," Journal of Membrane Science, 2012, 403–404, 58–70.

Alan D. Sharpe has significant work experience with IX resins and RO membranes. He began his career in 1972 with Rohm and Haas, where he worked in the marketing and development engineering of IX resins. Since 2007, Sharpe has been involved with the project team for RO membranes and business development for LANXESS‘ Lewabrane in the U.S. He holds bachelor’s degrees in chemical engineering and chemistry from Bucknell University and an MBA in marketing from Temple University. He may be reached at [email protected].

Carsten Schellenberg studied macromolecular chemistry and received his Ph.D. in colloid chemistry at the Max Planck Institute of Colloids and Interfaces located in Potsdam, Germany. He started his industrial career working in different technical and commercial functions at Ciba Specialty Chemicals and BASF. In 2012 he joined LANXESS with responsibility for the global R&D activities in the field of RO membranes at the manufacturing site in Bitterfeld-Wolfen (Germany). He may be reached at [email protected].

For more information, visit lpt.lanxess.com.