Since continuous casting was introduced in the steel manufacturing industry in the 1950s, engineers have continually perfected the process. A tweak here, some new technology there, and over time manufacturers are making steel with more efficiency and at greater rates than few thought possible 60 years ago.

All of this, however, has placed a significant strain on the treatment of cooling water for reuse in the casting process. Simply using municipal water to meet ever-increasing production requirements is impractical for financial reasons because thousands of gallons per minute are required. Recycling process water is critical to the economics of steel manufacturing. Missing just one day of production every six or seven weeks while the water recycling system catches up with demand can result in millions of dollars in lost revenue annually.

Eliminating scale

The primary requirement for the recycling of cooling water to the casting process is to eliminate the scale and other total suspended solids (TSS) that accumulate during the cooling of molten steel. Scale is produced when the heated steel is exposed to oxygen, creating a tough gray or black coating on the surface.

To remove the scale, a Midwestern steel manufacturer sends its process water to a large pit where the oxidized metal can settle to the bottom. The water is decanted and then sent to sand filters to remove any residual scale and TSS. The water is then sent to cooling towers and back to the caster spray water cooling process.

Increased production rates at the plant, however, mean that water is being sent to the settling pit at an increased flow rate. Therefore, scale is accumulating at the bottom of the scale pit much faster than the original design rate, compromising the effectiveness of the settling process.

The plant’s settling process was designed for water entering the pit to take approximately 35 minutes to travel the length of the 80-foot tank before entering the sand filters. This would provide enough time for the scale to react with a flocculent and fall to the bottom of the 12-foot-deep tank.

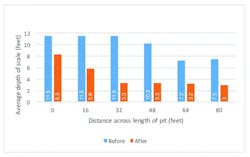

Today water travels from one end of the pit to the other sometimes in as few as six or seven minutes because scale accumulations at the bottom of the tank often exceed 9 feet, effectively reducing the capacity of the settling pit. Optimal settling occurs when scale accumulations are 5 feet or less.

To address the scale buildup, workers periodically dug scale out of the pit with a clamshell excavator while the plant was in operation. Though successful in dredging the pit, this technique created an increase in the amount of scale and TSS overflowing the pit and being sent to the sand filters, effectively negating the settling process. The turbidity during the excavation was as high as 200 to 500 Nephelometric Turbidity Units (NTU), placing an unacceptable burden on the sand filters. This also resulted in TSS levels that had the potential to damage the caster spray water cooling process.

Next, plant management turned to its water treatment supplier, which recommended a change in chemistry that enabled the TSS coagulation to occur at a faster rate. This, however, only increased the volume of scale in the pit.

The consequences of water with higher TSS levels being sent back to the casting process are significant. Cooling water is sprayed on the molten steel exiting the caster mold with fine-tipped nozzles. Any buildup in the nozzles could limit the flow and proper distribution of the cooling water, resulting in the inadequate cooling of the molten steel. This has the potential to disrupt the manufacturing process.

To prevent this from happening, production is halted on a regular basis so workers can excavate the settling pit with a clamshell. Time spent waiting for the pit to be cleaned has the impact of negating the process improvements made throughout the years in other parts of the steelmaking process.

Impact of submersible pump with auger

A submersible slurry pump solution

As a result, plant management and the water treatment company turned to MPW Industrial Services for a solution. Engineers from the company’s industrial cleaning and water purification divisions evaluated the plant’s production requirements and the settling process.

Working as a team, the services provider, the steel company and the water treatment company quickly determined that a submersible slurry pump lowered into the settling pit could remove the scale. This slurry pump includes an auger that loosens up the scale lumped at the bottom of the pit and pulls it toward the pump without kicking up any appreciable scale in the pit.

The slurry pump and auger are lowered into the pit with a crane on average three days per week depending on the plant’s production rates and the grade of steel being manufactured. The goal is to pump a 50-to-50 mix of water and scale to an adjacent dewatering pad while generating less than 50 NTU in the pit. In one eight-hour shift, the slurry pump and auger can remove approximately 30 percent more scale than the plant generates in a typical 24-hour period.

Steelmaking production is now interrupted only when the continuous caster process requires routine maintenance, which is generally every five to seven weeks. Since the introduction of the slurry pump and auger as well as the improved flocculent from the water treatment firm, no production delays have occurred because of excessive scale in the pit. Furthermore, the services provider is developing ways to automate operation of the slurry pump and auger and its engineering team is designing the next phase of the project to include an overhead gantry that will allow for a more continuous scale removal process. The goal is to eliminate the scale as an interference to steel production as well as the need for the clamshell excavation of the pit.

In addition to scale, cooling water from continuous casting contains oil and grease, both of which need to be removed before re-entering the process. Previously the plant used rope skimmers to rid the process water of oil and grease. Recently, the services provider has worked with plant management and the water treatment firm to evaluate alternative, more efficient skimming technologies.

No doubt the individuals who pioneered the continuous casting of steel would be hard-pressed to recognize some of the technology in today’s mills. Nonetheless, they would applaud the commitment to continuous improvement in all aspects of the process, including the recycling of cooling water.

Jim Neville is executive vice president for MPW Industrial Services. With nearly 3,000 employees and 72 locations in the U.S. and Canada, MPW provides industrial cleaning, water purification, facility management and environmental management services to customers in the power generation, primary metals, chemicals, refining, oil and gas, automotive, food and beverage, and pulp and paper industries. MPW’s headquarters is in Hebron, Ohio. For more information, visit mpwservices.com.