Wash & Rinse

By Shilpa Tiku

• Experience counts in the water and wastewater treatment market segment serving the U.S. food & beverage industry, but price is increasingly a competitive factor, finds a Frost & Sullivan analyst.

The diverse food processing industry includes a range of sectors such as the following: fruit and vegetables, dairy products, meat and fish, grain mill and bakery products, sugar and confectionery products, fats and oils, and frozen, packaged, and convenience foods.

Food and beverage is one of the most versatile industries and is traditionally a user of large volumes of water in the production process. Recent statistics indicate half the water used in the fruit and vegetable sector goes to washing and rinsing purposes. Dairies use water only for cleaning the process machinery. Large food or beverage plants easily utilize hundreds or thousands of gallons of water to make product ingredients. As a result, opportunities for water and wastewater solution providers are numerous, and this makes the market open for further development and penetration.

Treatment Processes

The most common water impurities in the food processing industry that need removal are suspended matter, microorganisms, organic matter, color, taste, odor and dissolved gases. Food industry effluents are generally characterized by high contents of biodegradable pollutants. Suspended substances constitute a large part of these pollutants, in addition to the high BOD and COD concentrations of the effluents.

These effluents are treated with biological methods as a primary treatment. Nitrogen and phosphorus concentrations in them are also reduced. The removal of suspended substances is sometimes completed by a settling process after adding coagulants to the effluent.

Other contaminants of food-processing wastewater, particularly from meat, poultry and seafood processing facilities, are pathogenic organisms. Wastewater with high pathogen levels must be disinfected prior to discharge. Typically, chlorine (free or combined) is used as a disinfectant. Ozone, UV radiation, and other nontraditional disinfection processes have steadily gained acceptance due to stricter regulations on the amount of residual chlorine levels in discharged wastewater.

Market Driver

An already existing strong installed base of treatment equipment in the U.S. food and beverage industry has meant demand for new installations is limited. Due to the maturing nature of the market, however, the potential for replacement and demand for upgrades are still strong. This is particularly the case with demand for technologies that offer reuse and recycling potential, including advanced/tertiary treatment in the wastewater segment.

Market Restraints

Economic Recession — The U.S. is one of the hardest hit countries by the ongoing economic recession. As a result, both industrial activity (manufacturing sector in particular) and related investment in water and wastewater treatment were put on hold. It's anticipated, however, that the long-term impact of this restraint will recede, and investment in environmental expenditure will resume.

Market Maturity and Consolidation — Market maturity, coupled with the competitiveness and complexity of the food industry is the main restraint for the water and wastewater treatment suppliers in this industry. Continuing market consolidation is raising the bargaining power of industry participants and making manufacturers much more demanding in their purchasing decisions.

Revenue Forecasts

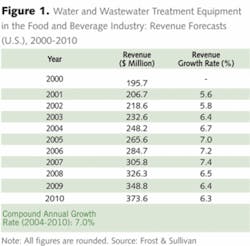

Figure 1 shows the revenue forecasts for water and wastewater treatment equipment in the food and beverage industry from 2000 to 2010.

Market Participants

Competition is still mostly fragmented and extends from technology specialists and niche participants to turnkey contractors and full service providers. Successful factors include sector specific know-how, partnerships, ability to respond to changing market conditions, and capabilities to innovate and provide cost-efficient solutions.

Food and beverage is a fairly dynamic market, where the pressure for supplier excellence and customer specific services are becoming increasingly strong. Increasingly aging infrastructure is driving growth of the repair and replacement market. From a purely financial standpoint, most food processors would opt to enlarge their existing plants rather than find new sites.

Moreover, regulation and legislative compliance are driving the technology upgrade markets. Expansions and extensions to existing systems are the other emerging opportunities in this market. This clearly shows there's strong competition in choosing the right process and technology specialist in the food industry. Critical success factors for suppliers are reliability and output quality, as well as safety of the system. Customers also rely on industry experience and past references before considering a new supplier in this market. Strong quality performance is a key market entry barrier and also forms the basis for customer loyalty. Pricing and servicing, which are emerging as strategic priorities for purchasing, offer product differentiation and competitive advantage to participants.

Some leading players in the market include Siemens Water Technologies, Nalco, GE Water & Process Technologies, Andritz, Parkson Corp., ITT and EIMCO Water Technologies, to name a few.

Siemens Water Technologies is currently dominating a large portion of the equipment and technologies in this market, and is rated by all customers as the best in overall service. The brand name is the most recognized in the U.S. food and beverage sector. The company recognized the need for consolidation of the very fragmented water and wastewater industry and acquired other top brands to increase its capabilities.

EIMCO Water Technologies, a unit of GLV Inc., is well recognized for its unique and exemplary customer and value-added service capabilities.

Customer Trends

Customers essentially invest in products that not only meet technological and regulatory specifications, but are cost efficient as well. As such, price plays a major role in the purchasing decision. While many product related qualities are now taken for granted, pricing is clearly becoming the key competitive factor for supplier differentiation in the food industry.

Conclusion

The U.S. food and beverage industry will continue to be lucrative in the foreseeable future. Industry standards and business practices will continue to be driven by both regulatory mandates and consumer tastes.

About the Author: Shilpa Tiku is a research analyst with Palo Alto, CA-based global growth consulting company Frost & Sullivan's North American Environmental & Building Technologies practice. Since August 2003, she has analyzed trends in U.S. water and wastewater treatment, waste management, and air pollution control markets. Contact: [email protected] or www.frost.com