Treatment System Extracts Value from Acid Mine Drainage

Battelle has developed a technology to remove sulfate ion and metal cations from acid mine drainage. The Acid Mine Drainage Value Extraction Process (AMD VEP) is based on a novel adaptation of liquid-liquid extraction. The process converts AMD to purified water as well as saleable products, such as potassium sulfate and iron sulfate. The result is a cost-effective method to purify AMD from metals as well as sulfate without generating a waste sludge.

A 30 gpm demonstration plant in St. Michael, PA.

The AMD VEP is being developed and demonstrated with funding from Winner Global, LLC in Sharon, PA, and the Pennsylvania Department of Environmental Protection. Winner Global is launching a business based on the technology. The company has been fielding numerous inquiries on the process from mining and environmental companies in the Pennsylvania, West Virginia, and Ohio region.

The development team filed a comprehensive patent around flotation liquid-liquid extraction technology which emerged from this $3 million process development project. The intellectual property was derived from existing Battelle know-how in the area of liquid-liquid extraction of chromium from process water.

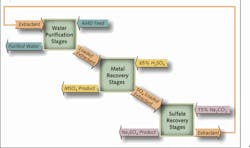

Figure 1 describes the AMD VEP technology. The AMD water laden with sulfate and iron feeds into the Water Purification Stages where the water is sequentially contacted in a counter-current flow path with an extractant solution formulated to pull these ions from the aqueous phase. After passing through the Water Purification Stages, the purified water exits the process and can be discharged to a stream, reused as clean process water, or fed to a municipal drinking water plant.

The Water Purification Stages are a set of four mixer-settler units, which are two-compartment tanks. In the first compartment, a mixer pulls the extractant and the water into a mixing chamber. The two fluids are intimately mixed with a residence time of 60 to 90 seconds. From the mixing chamber, the combined effluent flows into the settling chamber where the organic extractant phase disengages from the water phase. The extractant, now containing the iron and sulfate ions, overflows an exit weir in the settling chamber and is separated cleanly from the water phase which underflows the same weir and exits as a separate stream.

The extractant, now loaded with the iron and sulfate ions, flows to the Metals Recovery and then the Sulfate Recovery Stages of the process. The Metals Recovery Stages are a set of two to three metal cation recovery tanks. The extractant flows counter-clockwise with an aqueous sulfuric acid solution to form an iron sulfate concentrate that is harvested for reuse.

The Sulfate Recovery Stages remove sulfate from the extractant, which again flows through a series of mixer-settler tanks in a counter-current fashion. The extractant is contacted with potassium carbonate, a basic aqueous solution, to produce a potassium sulfate concentrate. The extractant exits the last mixer-settler of the sulfate recovery section regenerated and ready to contact a new stream of AMD feed water. The potassium sulfate concentrate is collected and stored for sale or reuse.

One major advantage of the AMD VEP technology is that it generates purified water that can be within drinking water standards for iron and sulfate, while converting the iron and sulfate into usable products. As a result, the process has no significant waste stream.