Cheese Producer Solves Wastewater Issues with MBBR System

By Chandler H. Johnson

Leprino Food Co. in Roswell, NM, is the world's largest producer of premium quality mozzarella and the largest U.S. exporter of whey and lactose products.

Leprino's existing wastewater treatment plant (WWTP) was an extended aeration activated sludge process designed for 19,000 lb/d of BOD but was being overloaded at times to >30,000 lb/d during spill events in the factory. The overloading didn't make operation of the existing system easy.

Polymer addition was required to ensure settling of mixed liquor suspended solids (MLSS) in the clarifier, which increased treatment costs. Use of mechanical aeration devices in addition to a fine bubble aeration system was required to maintain a positive dissolved oxygen concentration in the basins, which translated into extra costs for the treatment facility.

The ultimate challenge was to add a beneficial treatment system that would complement the existing treatment system and provide for stable operation.

The overall design concept of this project used a combined biofilm and activated sludge system where the Moving Bed™ Biofilm Reactor (MBBR) system acts as a pre-treatment device ahead of the existing activated sludge system. Leprino looked at the AnoxKaldnes MBBR as a means of pretreatment to remove 30-40% of its easily degradable organic matter and to act as a buffer when shock loads were headed toward the treatment plant.

In operation, the MBBR system effluent flows directly, via gravity, into the two parallel activated sludge basins, which consume the remaining organic matter contained within the wastewater.

The first design phase of the upgrade was based on the filling degree of media in the MBBR reactor to 33% its liquid volume. The design flow is an average of 0.800 mgd with a BOD load of 23,350 lb/day.

At this design, BOD load and media fill fraction, the estimated removal of soluble BOD is 35% leaving <15,178 lb soluble BOD/day to be treated by the existing activated sludge units.

Since the maximum filling capacity of an MBBR is 70% of liquid reactor volume, the overall treatment capacity of the MBBR can be upgraded by just adding media to the reactor and extra air to the existing aeration grid system. In order to meet future capacity, the first increase in media fill will be to 45% of the reactor's volume. At this second stage, the system will treat an average influent BOD load of 26,700 lb/day to an effluent soluble BOD of 16,020 lb/day (40% removal of soluble BOD) at a flow rate of 0.914 mgd. The final media increase will be to 70% fill of the reactor's volume. At this maximum fill of carrier media, the system will treat an average influent BOD load of 30,275 lb/day to an effluent soluble BOD of 16,700 lb/day (45% removal of soluble BOD) at a flow rate of 1.037 mgd.

Results

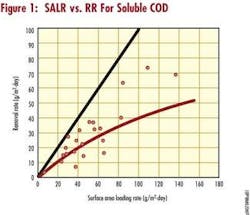

The table below shows data from the first two months of start up. Both the influent and effluent values of soluble COD (SCOD), total suspended solids (TSS), ammonia-nitrogen (NH3-N), nitrate-nitrogen (NO3-N), total dissolved solids (TDS), total phosphorus (TP) and chlorides are shown. The average removal rate for the system has been 56% of the SCOD. The graph above shows the surface area loading rate vs. removal rate for SCOD. The red line represents the regression analysis of the data and supports a >40% removal of SCOD up to loads 17.3 lb/1,000 ft2 day.

Conclusion

Operationally, the plant has significantly improved operation overall. The polymer usage in the secondary clarifiers has been completely turned off due to the improved settling rates of the MLSS in the clarifier. Return sludge pumping rates have decreased due to the increased concentration of settled MLSS in the clarifier. In addition, because of better settling rates, the surface aeration devices have been turned off since the extended aeration basins are now capable of maintaining a positive dissolved oxygen concentration (>2 mg/L). The reduction in use of all these items has a positive effect on the cost of treating the wastewater resulting in a cost savings for Leprino Foods WWTP.

About the Author:

Chandler H. Johnson is president of the Providence, RI, office, of AnoxKaldnes Inc. a unit of AnoxKaldnes International with offices worldwide. Chandler has overall responsibility for the Integrated Fixed Film Activated Sludge (IFAS) and MBBR product lines in North America. He has more than 10 years experience in the field of wastewater treatment and, specifically, the MBBR process.