Power Plant Demonstrates Success of Secondary Waste Reuse in Power Production

By Chuck Dale

Much attention has been recently given to the use of municipal wastewater treatment plant effluents as a source of industrial and agricultural reuse water throughout the world. There is a growing interest in the many benefits afforded by the reuse of these sources to satisfy the ever-increasing demands placed upon the world's fresh water resources.

A 49 megawatt natural gas turbine power facility in Lodi, CA, has been using reverse osmosis (RO) technology to treat secondary effluent from a municipal treatment facility for over eight years. Based on the success of this and similar projects, and by the knowledge gained over the last decade, effluent reuse has become a significant advantage in the siting of new power production facilities.

Project History

In the early 1990s, a mid-sized California-based utility issued requests for proposals to reuse local wastewater treatment plant effluent as the feed to its two new power facilities. While the political motivations were strong, the financial reward of receiving essentially free feed water made the apparent risk of using municipal effluent more than worthwhile. This avoided operational cost was potentially worth over $60,000 per month per site based upon an alternative water source cost of $1.50 per Kgal.

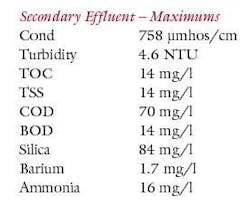

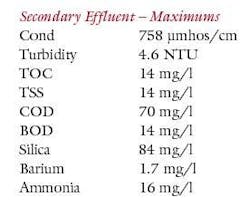

In order to accept the secondary effluent feed water as the sole supply to the Lodi plant, the utility sought a qualified supplier and a treatment system capable of guaranteeing the long-term operation of the water treatment system with the following feedwater specifications:

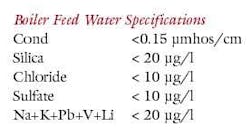

The power plant would require the vendor to provide 200 gpm of treated water for cooling tower makeup, 65 gpm of treated water for general plant usage and another 290 gpm of demineralized boiler feed water.

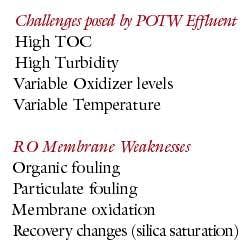

Because Electrodialysis Reversal (EDR) systems do not remove silica from their product stream, the selection of EDR as the main desalting mechanism was ruled out as it would have significantly increased the ion exchange resin costs. Reverse osmosis systems would be subjected to considerable fouling risk but the reward of high silica rejection was worth further investigation.

Given the requirement to use the secondary effluent as feed water and given the advantages expected from the use of thin film composite RO membranes, it was deemed appropriate to conduct a pilot study to quantify the fouling behavior in the full size RO system, and to determine the appropriate flux rates to minimize that fouling.

Based upon the proposals received, vendors were selected to design and build the water treatment systems for the plants as long-term own-operate contracts. The contract terms for each of the two sites mandated that the vendor perform a pilot study as a proof of concept prior to the design of the treatment system for their site.

Pilot Study

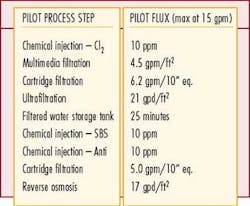

At the Lodi facility, a trailer mounted pilot system was assembled to operate with various pretreatment components and configurations. The system was designed to run at output flows between 5 gpm and 15 gpm using spiral polysulfone UF and thin film composite RO membranes in, see Chart 1.

The pilot trailer operated with all of the aforementioned process steps in place, and it was determined that the thin film composite RO membranes were capable of efficient operation in the secondary effluent application.

During the initial operation and with the ultrafiltration system running, the RO membranes were operated for the first four weeks and their fouling rate was observed. During the fifth week, the ultrafiltration system was bypassed in order to assess the relative importance of the UF process in the determination of the fouling rate of the RO membranes. Within days it was obvious that the UF was in fact essential to the project.

During the two month period starting in January 1994, it was further determined that the RO membranes required more protection than multimedia filters and cartridges alone could provide. In short, the ultrafiltration process was confirmed to be essential to the success of the design.

The system configuration was thus solidified and individual unit flux rates were established. During the last three weeks, the pilot study was run according to the selected configuration and parameters, with the observed fouling rate deemed acceptable for the full scale plant design.

Full Scale System

Based upon the success of the pilot study, in April of 1994, Ionics was released to proceed with the detailed design and construction of the water treatment system within the 10-year own-operate contract. The project was rightly termed a "precedence-setting project".

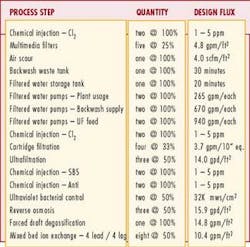

The final full-scale system configuration can be seen in Chart 2.

Operational since March of 1995, the UF/RO based system has been supplying cooling tower makeup and demineralized water to the 49 megawatt Lodi plant with maintenance levels as initially projected.

Membrane Performance UF Membranes

The pilot study data and the full scale system exhibited excellent UF filtrate quality levels. The initial Silt Density Index (SDI15) of the UF membrane system averaged 0.2 with a range of 0.1 to 0.6. The longer-term SDI results show a classic inclined saw-tooth performance reduction as the UF membranes are fouled and cleaned throughout their service life.

UF membrane cleanings have been performed on-site every three to four months based upon the system design tolerance for flux decline. The cleanings have been performed with slight variations of the chemical recipe over the years but in general they are performed as short, high-pH, chlorination cycles.

The chlorine solution, with a starting free chlorine level of about 200 ppm, and at a pH of 10-11, is recirculated at low pressure through the UF membranes at 20 gpm per vessel while slowly raising the temperature to about 43° C. At temperature, the solution heating is stopped and the recirculation continued until the gradual cooling of the CIP solution has lowered the temperature to about 30° C at which time the spent cleaning solution is rinsed from the UF train.

RO Membranes

Both the pilot study data and the full scale system exhibited excellent RO permeate quality levels. The initial conductivity-based rejection rate of the RO membrane system was 99.1% at a typical recovery of 75%. The RO membranes' performance also showed as expected a declining saw-tooth performance reduction as the RO membranes were fouled and cleaned throughout their service life.

RO membrane cleanings have been performed off-site every three to five months with various commercially available specialty recipes over the years, but in general, they consist of a warm, high-pH, surfactant cleaning. The high-pH RO membrane cleanings are performed such that the solution is heated until the peak temperature is met and then the recirculation continues during the cooldown period. At every other cleaning, a low-pH scale reducing cleaning sequence is performed after the high-pH cleaning.

Membrane Longevity UF Membranes

The spiral-wound 8'' x 40'' UF elements initially installed in 1995 were thin film polysulfone membrane elements manufactured by Ionics. These initial 216 UF membranes were in service for the first 73 months of the plant's operation. They were cleaned every three to four months during their service life and their replacement was scheduled as soon as their filtrate reached an SDI15 value of 3.0.

The first train reached that point in the 69th month, while the final train reached that level on the 71st month.

Exact replacement elements from the original production facility were no longer available and dimensionally equivalent replacement UF elements were obtained in 2001. The performance of the replacement elements was nearly identical to the original UF elements and the fouling and performance degradation over time has produced a data set nearly identical to that of the original UF element set.

Based upon the original sets 73 month life, and the similarities in the performance degradation rate, the second set is projected to require replacement in 2007.

RO Membranes

The RO membranes initially installed in 1995 were thin film polyamide membrane elements also manufactured by Ionics. These 108 initial membranes were in service for the first 54 months of operation. They were fouled and cleaned about every three to five months during their service and were scheduled for replacement when their cost-cleaning performance tests indicated less than 96% rejection. Cleanings have been performed off-site using a variety of commercially available blended RO membrane cleaners.

After about the 49th month, many of the elements were becoming increasingly difficult to effectively clean and it was determined that they should be replaced in the coming months.

The original RO membrane model number had been superceded and were no longer available. Dimensionally equivalent replacement RO membranes were obtained in 1999. The ionic rejection of the replacement membranes was slightly better than the original RO membrane set. The fouling and cleaning requirements and the performance degradation over time also is producing a data set nearly identical to that of the original membrane set.

Based upon the original set's 54 month life, and the similarities in the performance degradation rate, the second set is projected to require replacement in 2004.

Looking Back

The power plant, after over one hundred months of operation, has reused many hundreds of millions of gallons of secondary effluent and has not added to California's omnipresent water supply challenge. It truly pioneered a significant contribution to the solution.

The owner of the Lodi plant has benefited from the avoided cost of feed water, is a valued solution contributor in the regional water supply picture and has been able to have stable predictable treatment costs along the way. By outsourcing the water treatment system and its operation, this site has been allowed to focus its resources strictly on the intricacies of power production rather than the risk of water treatment system upsets and their unexpected costs.

By pioneering the reuse of municipal effluent, the Lodi plant has paved the way for many power production facilities to reduce feed water supply constraints, to increase supply reliability, reduce or eliminate feed water costs, and avoid the inherent political pressures that often result in a potential plant site remaining undeveloped. Citizens are more likely to prefer that new housing developments use the limited potable water supplies over power production facilities in areas of severe water supply constraints. This in essence precludes the dedication of fresh water resources to power production facilities in many areas.

About the Author:

Chuck Dale is an Account Manager at the San Jose, CA, office of Ionics Inc. Over his last 15 years with Ionics, Dale has been instrumental in the process design and project coordination of hundreds of ultrapure water systems, including major systems for Calpine, ConocoPhillips, Florida Power & Light, Hewlett-Packard, Intel, Micron, Seagate, and Texas Instruments. Dale received a Bachelor of Science degree in Business Administration from San Jose State University.