Company to Recycle/Reuse Metal Finishing Wastewater

Anoplate Corp., located in Syracuse, NY, is a leader in the metal plating industry. It has been offering a range of metal finishing services to a broad base of customers since 1960. These services consist of plating, anodizing, conversion coatings, and vacuum impregnation. Their customers include the aerospace, computer, electronic, military, medical, optic, and recreation industries.

Like many other industrial plants, Anoplate has to treat its wastewater. A physical/chemical process is used which involves adding the chemical hydroxyl alkalinity to the wastewater to produce precipitated, metal hydroxide waste. This treatment process produces effluent that meets EPA quality requirements for discharge, but is not sufficient for recycling/reuse.

Anoplate decided to set a goal to reuse its wastewater by the end of the year 2001 in its new plant in Syracuse. The first step toward meeting this goal was to purchase a filter system that would lower TSS and metal contaminant levels to meet reuse-quality requirements. The new filter would also have to serve as a pre-filter for the future deionized water exchange system to prevent cross contamination. An AquaDisk™ cloth media filter and a traveling bridge sand media filter were considered for this purpose.

Filter Installation

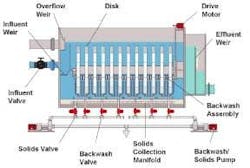

Following a successful pilot study, Anoplate purchased one AquaDisk™ package filter from Aqua-Aerobic Systems, Inc. The filter was delivered fully assembled for on-site installation and included: a factory prepared tank, disks covered with model 102 media cloth, a backwash cleaning system, a high-pressure spray cleaning system, a solids removal system and a fully automatic control system.

Prior to actual start-up, the unit was inspected and tested by Aqua's service technicians and Anoplate's operators were shown how to operate and maintain the equipment.

Filter Operation

The primary function of the filtration system is to filter metal hydroxides from Anoplate's plating wastewater and to pre-filter the effluent before it goes through the future deionized water exchange system.

Clarified effluent flows by gravity through the cloth media of the stationary hollow disks. The filtrate exits through the hollow shaft which supports the individual disks. As solids accumulate on the surface of the media, the water level surrounding the disks rises. Once a predetermined level is reached, the disks rotate and the media surface is automatically vacuum backwashed clean. Solids settle to the bottom of the tank and are then pumped to a digester or to the plant headworks.

Design Characteristics

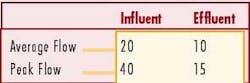

The AquaDisk Filter reduces TSS and metal contaminants to required reuse-quality levels. The plant's actual average daily flow is 25,000 gpd with a peak daily flow of 35,000 gpd. To accommodate future plant expansion, the filter was designed to handle an average daily flow of 288,000 gpd with a peak daily flow of 900,000 gpd.