Rising Steel Costs Could Impact Water Industry

By Sylvie Dale, Associate Editor

Reacting to China's insatiable drive to build, the price of steel is way up for the year. In fact, things are changing so fast that some suppliers to the water & wastewater industry are waiting until delivery to quote their customers a price.

The spot market price for hot-rolled sheet metal was $585 a ton in April 2004, according to Purchasing magazine. That's up from $310 per ton in December and from about $260 per ton last June. For the same period, structural steel has increased nearly 50 percent from $365 per ton to $546.

Pipe, alloys, galvanized steel conduit, structural steel, rebar and other building materials now cost significantly more than they did in June 2003. These materials are following spikes in auto scrap, nickel, copper and other base materials.

With prices going up just as the American economy begins to rebound, water and wastewater construction projects for 2004 are vulnerable to delays and cost overruns. Most construction material suppliers are now adding a surcharge to their prices. Vendors and contractors which have had to pay more for their materials are now faced with the unpleasant question of whether to increase prices for their customers or to absorb their extra cost and risk their own demise.

Water and wastewater projects will feel the pinch because of their heavy reliance on steel. Most of these projects do not have escalation clauses, according to Bill Didden, Director of Sales for Separation Products at Hayward Industrial Products.

"Even if there are, the way some material costs have gone up, it will take quite a while for the various indices to catch up. The exponential increases on materials such as stainless steel have probably put a lot of people in a bind."

The situation may be especially unpredictable for those projects which are in the middle or earlier in the cycle.

"Orders for equipment may have been let, but if material was not purchased prior to the increases, the manufacturer could be faced with an order that he cannot produce as the out of pocket cost may far exceed the purchase order price," Didden said.

For example, if a manufacturer has an order to provide 1,000 valves (or feet of pipe, etc.) at an arbitrary price of $115 per unit, which consists of $100 cost of production and $15 for overhead and profit, and the increasing material cost forces the manufacturing cost to jump 30 percent, all of sudden this manufacturer is $15 in the hole, Didden said. The manufacturer can go back to the purchaser and ask for more money, or try to get the purchaser to choose an alternate material, but both of these routes bring delays.

"In two of the three scenarios, project completion can definitely be jeopardized and can make for some serious lawsuit possibilities. As a supplier of goods and services, you certainly want to try to cooperate and work with your customers. However, at the end of the day, one has to show a profit to be able to pay your own workforce and suppliers."

The industrial water and wastewater industry will see price increases on all construction projects for a range of reasons, said Kurt Voss, a senior procurement manager for Black & Veatch.

"Some of the effects we are seeing are not really because of availability but because of world economics, and in others, it's the opposite — availability is becoming critical, such as in galvanized metal conduit."

"The list price of steel hasn't dramatically increased, but the base material — which is primarily scrap steel — has gone through the roof, primarily because of the Chinese demand right now for that scrap on a global nature," Voss said. "They are buying it up worldwide."

Just as local businesses don't list their prices with sales tax included, most minimills are not adding to their prices, but tacking on a surcharge. The surcharge represents their best guess on where prices will go during the next month.

For his work as a senior procurement officer with Black & Veatch, Kurt Voss uses Nucor-Yamato Steel Co. as a benchmark for the expected price of rebar and structural steel from minimills. The major indicator in this price is shredded auto scrap, which is the basic raw material of the minimills.

At the end of December 2003, Nucor-Yamato was buying shredded auto scrap from Chicago exchange for $162/ton. On Jan. 9, 2004, Nucor-Yamato announced it would start adding a surcharge to its orders to defray the rising cost of scrap metal. It started with a $20/ton surcharge for January.

That surcharge grew to $49/ton in February, $93/ton in March, and $120/ton in April. The market saw some relief with the recent drop to $68/ton for May shipments, using Nucor-Yamato's figures. However, on April 13 the company announced a general price hike of $30/ton on all construction materials.

Nucor-Yamato itself derives its price by starting with the current American Metal Market, Chicago "Consumer Buying Price" for shredded scrap, then subtracting a base price of $162/ton.

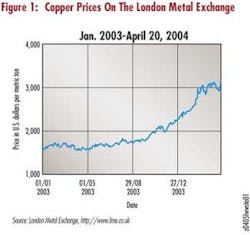

Copper

The price of raw copper is up greatly. In November 2003, copper on the London Metal Exchange was $1,987/metric ton. In February 2004, it hit $3,001/metric ton, and by March 30, its price was $3,105.

That price is likely to start declining soon. "Copper has a tendency to rise in the first half of the year and drop in the second half of the year, and the demand for copper is in May for summer purchasing," Voss said.

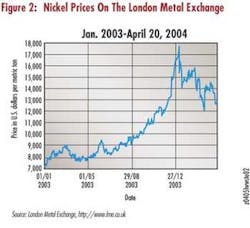

Nickel

In January 2003, the London Metal Exchange listed nickel at $7,210/metric ton, and a year later it was $17,770/metric ton. It has dropped since then to the $13,885/metric ton range by the end of March 2004, but that's still nearly double what it was in 2003.

Nickel is only one of the components in alloy pipe. Each of the base components in alloy pipe can have an effect on the overall pricing of the material.

Causes for Higher Costs

Scrap consumption from China is probably the number one cause for the rise in steel prices.

"The production capacities of the minimills is relatively normal," Voss said. "So it's not a production capacity issue, it's simply a base material shortage."

When demand and domestic prices for steel have surged in the past, U.S. companies could fall back on cheaper imports to meet their needs. However, a weaker dollar and higher energy prices have made steel imports less of an option. Steel imports are down about 50 percent so far this year, according to the News Journal in Wilmington, DE.

Industry response

Without a doubt, suppliers and contractors have to do something to make sure the price of steel doesn't mean the end of their business.

"It's a very delicate issue in that we've already seen a number of steel suppliers filing Chapter 11 because of owners that are unwilling to absorb the surcharge increase," Voss commented.

Suppliers are limiting the amount of time for which a price quote is good. Just a few weeks ago, that span of time was 6-8 weeks, according to a survey of Water and Wastewater Equipment Manufacturers Association Inc. (WWEMA) members. Now, it's more like 30 days.

Contractors and vendors who buy and use steel for their projects are caught between a rock and a hard place. These companies strive to make their contracts as competitive as possible and want to avoid changing them after they've been agreed upon.

An increasing number of vendors are building a cost escalation formula into their contract price which adds surcharges after 45 to 60 days.

Some general construction companies are only guaranteeing their rebar and structural steel prices for seven days.

The base proposal validity period has to be tailored to the client, the package, and the industry being served, Voss said. Municipal customers have a markedly different response than industrial customers to price adjustment requests.

For already awarded work, municipalities are reluctant to compromise on costs of materials because of the inflexibility of their financing.

However, producers and generators of significant revenues tend to be more open to negotiating the price of materials even after the contract has been awarded. Many of these customers understand that if their vendor or contractor cannot survive the price spike, they won't be able to continue working with them on future projects.

As vendors and contractors feel the pinch, they are getting creative with solutions, like giving the customer the option of issuing a purchase order early for the steel needed in the project. This allows the customer to pay today's price for the materials without having to worry about a surcharge.

Peak Pricing

Choosing a conservative stance, industry members have avoided guessing where steel prices will peak for 2004. However, a few factors may help in the reduction of prices in the next few months, Voss said.

"A coke producer in West Virginia that is currently off line will be coming back on line at the end of the second quarter, which means it will probably be up to full production in the third quarter, and that might alleviate some of the pressures."

"I've also read that the cost of transportation of the scrap steel going to China is going up, so perhaps the increased cost to China may abate some of their demand," Voss said.

He said that Chinese mills are reportedly increasing their production by 30 percent to accommodate the infrastructure improvements in China. Once these mills are able to handle greater capacity, the nation will be better able to meet its own demand for steel.

In addition, Chinese factories shut down for the monsoon season in the spring, which should reduce demand until fall.

For May, Nucor-Yamato reduced its surcharge to $68/ton but at the same time increased prices on all its building materials by $30 per ton.

The surge in demand for steel has the potential of being a boon to steel suppliers this year. From their perspective, steel mills have recognized an "improving" market — demand for their product is increasing, industry inventories are low, growth remains in mill production capacity and tangible conditions (i.e.: global demand for scrap steel) has intensified consumer supply and demand concerns.

As such, Black & Veatch is seeing a trend in mill's increased finish product published prices which is independent of the surcharges imposed.

"As demand rises and supply remains relatively steady, mills are leveraging the market opportunity," Voss said.

"In one domestic steel mill example, published prices for their entire product line have risen $55 per ton in 2004. Is it coincidental that the latest increase, $30 per ton, occurred simultaneously with a delivered product surcharge decrease of $52 per ton? Not at all — in a capitalistic economy it's just timely business practice."

Vendors and contractors will probably follow suit for survival's sake and try to pass on at least some of their higher costs to the end consumer.

Whether steel prices will see a gradual decline in the coming quarter is a subject of continuing debate.

Black & Veatch's procurement managers are watching the market carefully to see how they will need to respond to changes in costs.

"We're waiting to see if there's any indication of a flattening of the curve or what we are hoping will eventually be a downturn in the surcharge curve of structural steel," Voss said.