Demonstration Trials Screen System at Beef Slaughterhouses

By George Anipsitakis

In an effort to find an economical way to reduce loadings to the main wastewater treatment process, full scale trials were undertaken at two beef slaughterhouses to demonstrate the performance of a rotating belt filter screen and its ability to remove organic matter and solids.

The Salsnes filter screen uses a rotating inclined belt filter with openings from 75 to 1000 microns and is marketed in the United States by Blue Water Technologies as a chemical-free mechanical process alternative to screening and/or primary clarification. Solids captured by the belt filter are discharged into a shafted screw conveyor container where they are pressed before exiting the equipment as dewatered cake. The model used at the trials was the smallest available model manufactured, the SF-1000, and was tested with both unscreened and already screened influent.

Plant A

Trials at Plant A were performed in August 2008 and again in October 2008 (eight operating days in total). At the times of the trials, Plant A was processing approximately 80,000 gallons of wastewater on a typical production day (56 gpm) and already operated two existing screens for preliminary treatment. The first screen was a stationary wedge wire-type discharging to a second rotating externally fed screen. The Salsnes filter screen was tested both downstream of the existing screens receiving screened wastewater and upstream of the existing screens receiving raw unscreened wastewater. Critical to the operation of the filter screen is the size of the belt openings. In these trials, belt openings tested were 350, 500, and 840 μm. The feed flowrate to the screen ranged from 16 to 37 gpm.

Results from the trials at Plant A are discussed below (the numbers in parenthesis correspond to numbers of different samples):

• When the Salsnes screen received raw unscreened wastewater the average constituent concentrations were as follows: 8,360 mg/L COD (5), 5,680 mg/L BOD5 (1), and 6,840 mg/L TSS (15). When the Salsnes screen was placed downstream of the existing screens, the wastewater contained an average 6,560 mg/L COD (8), 4,090 mg/L BOD5 (5), and 4,420 mg/L TSS (5). These values indicate that the existing screens already provide 21.5% COD removal, 28% BOD5 removal, and 35% TSS removal.

• When the screen received raw unscreened wastewater using a 350 μm belt, the COD removal averaged 23% (5), BOD5 removal was 41% (1), and TSS removal was 55% (15). These results indicate a better performance of the Salsnes screen compared to the existing screens. Using the Salsnes screen only, COD removal increased by only 1.5 %, but BOD5 and TSS removals increased by 13% and 20%, respectively. Under this set of trials the thickness of the cake produced ranged from 12 to 26% in solids and had an average of 18% (7) in solids.

• When the screen operated downstream of the existing screens using a 350 μm belt, the COD removal across the Salsnes averaged 15% (7), BOD5 removal was 42% (1), and TSS removal was also 42% (1). These results indicate that, if one combined the existing screens with the new Salsnes screen in series, the overall constituent removals become 33% for COD, 58% for BOD5, and 62.5% for TSS.

• When the screen operated downstream of the existing screens using the 500 and the 840 μm belts, only two measurements were collected per each belt size tested. The variability of the results does not allow a safe prediction of the screen performance using these two belt sizes. Under these trials one cake measurement was 12% in solids (840 μm) whereas the other was 21% (500 μm).

• Calculations, taking into account the then incurred costs in sludge conditioning chemicals and sludge disposal, indicated that a properly sized screen could provide a return on investment of less than one year.

Even though not all combinations of belt sizes and types of wastewater (already screened or unscreened) were tested, results from the Plant A trials indicate that, with the Salsnes screen, one can expect greater than 20%, 40%, and 50% removals of COD, BOD5, and TSS, respectively, from raw wastewater of this type using an appropriate size of belt openings. Furthermore, if the Salsnes screen is combined with existing coarser screens one could expect overall constituent removals of greater than 30%, 55%, and 60% for COD, BOD5, and TSS, respectively. Here, most tests were run and these removals were attained with a 350 μm belt.

Plant B

Trials at Plant B were performed in October 2008 (four operating days). At the time of the trials, Plant B was processing approximately 12,000 gallons of wastewater on an average production day (8 gpm) and already operated a stationary wedge wire screen for preliminary treatment. The Salsnes filter screen was placed upstream of the existing screen to receive raw unscreened wastewater containing 4,200 mg/L BOD5 (9) and 3,590 mg/L TSS (9). The numbers in parenthesis correspond to numbers of different samples. The feed flowrate to the screen ranged from 19 to 54 gpm. The different belts tested had openings of the following sizes: 350, 500, and 840 μm.

Results from the trials at Plant B are discussed below:

• When the screen was equipped with a 350 μm belt, the average BOD5 removal was 15% (2) and the TSS removal was 37% (2); though the variability of the two TSS results was significant.

• When the screen was equipped with a 500 μm belt, the average BOD5 removal was 26% (5), whereas the TSS removal was 49% (5). Under this set of trials, the thickness of the cake was measured once and contained 18.5% solids.

• Finally, when the screen was equipped with an 840 μm belt, the average BOD5 removal was 19% (2), whereas the TSS removal was 35% (2). Under this set of trials the thickness of the cake was measured once and contained 26% solids.

As with Plant A, results from the Plant B trials indicate that one can expect substantial constituent removal using this type of screen. Removals equal or greater than 20% and 50% for BOD5 and TSS, respectively, were attained from this facility’s unscreened wastewater. A belt with 500 μm size openings appeared to be the most appropriate option.

Comparison

Trials at Plant B were more systematic than Plant A in terms of testing different size belt openings and suggest that, if enough data were collected at Plant A, perhaps a 500 μm would outperform a 350 μm belt at Plant A as well. Much more data, however, were collected using a 350 μm belt from Plant A compared to the data collected from Plant B.

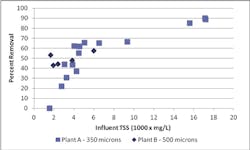

As expected, tests at both plants showed that solids removal increases with solids concentration in the influent to the Salsnes screen. Solids removal values as high as 90% were recorded at Plant A when the influent TSS concentration reached 17,000 mg/L.

Conclusions

In conclusion, the claim of the distributor for similar to primary clarification performance by the Salsnes screen appears to be substantiated by the data collected and discussed in this article. The benefit of matching the performance of a primary clarifier without having to build a tank is undoubtedly significant. In summary:

1. At Plant A, greater than 20%, 40%, and 50% removals of COD, BOD5, and TSS, respectively, were obtained using the screen (350 μm).

2. At Plant A, greater than 30%, 55%, and 60% removals of COD, BOD5, and TSS, respectively, were obtained when the screen (350 μm) was connected in series with the existing screens.

3. At Plant B, equal or greater than 20% and 50% removals of BOD5 and TSS, respectively, were obtained using the screen (500 μm).

As a general guideline for a maximum solids removal, it is advisable to perform field tests to be able to select the appropriate belt opening size that matches the characteristics of the wastewater to be treated. As with Plants A and B, it may be prudent to have at least two belts with different size openings available on-site to be able to match potential variability in the characteristics of the wastewater due to varying upstream processing conditions.

About the Author: George Anipsitakis, PhD, PE, is a senior engineer with Brown and Caldwell. The trials described in this article were performed when he was employed with Chastain-Skillman..