Ion Exchange/Filtration

Filtronics' Condor low flow solution for the removal of arsenic, phosphate, chromium, selenium, fluoride, antimony, lead, and other metals from drinking water is designed for flows of 5-125 gpm. The two stage filtration system offers redundancy of equipment and flexibility to reduce capacity when needed. Configurations include skid mount or wall mount systems. The system is completely automated, uses substantially less chemicals than are generally required for treatment, and produces no hazardous waste, while still producing potable water most often significantly cleaner and purer than required by stringent EPA regulations. Filtronics, 714-630-5040, www.filtronics.com

Media filter

Filtra-Systems has introduced the STiR industrial water filter, an automatic back-washable media filter featuring patented fluidization technology, which significantly improves filter performance compared to sand, anthracite and carbon media filters. By using eco-friendly black walnut shell media, the filter can regenerate the media throughout the 20-year life of the product. Black walnut shell media is not mined, is chemically inert, hard resilient and preferentially water wetted. Versatile enough for many applications, the filter is ideal for the mining, metal working, chemical and many other industrial waste water installations. Filtra-Systems, Farmington Hills, MI, 248-427-9090, www.filtrasystems.com

Filter pilot unitThe new MD-4 Cloth Media Pilot Unit is a fully enclosed, 53 foot, drop deck trailer. At its core is a 1-disk Aqua MiniDisk® cloth media filter with several aesthetic, operational and functional upgrades providing greater flexibility for each unique customer application. The MD-4 unit includes a fully equipped lab area with the ability to accomplish on-site analysis for most operating parameters such as total suspended solids monitoring and particle size analysis. Aqua-Aerobics, 815-639-4456, www.aqua-aerobic.com

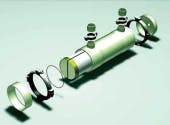

Filter vesselParker-Hannifin has introduced the new ParMax™ Filter Vessel, a high-flow capacity filtration solution for municipal water systems and other liquid applications. The filter vessel combined with ParMax™ Select filter cartridges can reduce the overall cost of filtration when compared to vessels containing traditional 2.5" diameter filter cartridges by yielding high-flow rates with fewer cartridges in a smaller, lower-cost vessel. With 500 gpm capability per cartridge, the vessels take up less plant floor space while the inside/outside cartridge flow traps particulate within the filter, thus eliminating vessel cleaning when changing cartridges. Parker-Hannifin Corp., Oxnard, CA, 877-784-2234, www.parker.com/processfiltration

Ceramic membranesSJE-Rhombus® now offers two new tubular ceramic membrane modules in its CFS™ product line (Ceramic Filtration Solutions). Priced to compete with polymeric membranes, the Bundled Ceramic Tubular Module and Monolith Ceramic Module are suitable for high flow rates. In addition to offering the new tubular design, the company will continue to offer its Flat Sheet Ceramic Membrane Solutions. All CFS™ products are designed for micro and ultrafiltration processes. SJE-Rhombus®, 888-342-5753, www.sjerhombus.com

Ultrafiltration

Koch Membrane Systems is helping companies reduce and reuse wastewater via Konsolidator™ ultrafiltration systems, which are designed for companies looking to reduce disposal wastewater costs in applications with high suspended solids. The durable membranes can handle a variety of processing conditions and can be cleaned easily using KMS' sponge balls. Fabricated from cost-effective, dependable components, the systems feature the company's patented FEG™ tubular membranes, with mechanical and chemical resistance properties that make it suited to tough applications. Koch Membrane Systems Inc., Wilmington, MA, www.kochmembrane.com

Cartridge filtersW. L. Gore & Associates is offering a new family of cartridge filters that improve water quality and reduce total cost of filtration for ultrapure water and de-ionized water used in the manufacture of semiconductors and silicon wafers. The company has used its expertise in ePTFE materials and membrane technology to engineer a family of filters that offer 3x the flow rate of best-in-class filters without sacrificing particle retention, and that can be easily substituted for filters in the field that no longer meet performance or cost requirements. W.L. Gore & Associates, Elkton, MD, www.gore.com/filters

Compressible media filterThe Schreiber Fuzzy Filter® is a high rate, compact, modular filter applicable to a wide variety of water and wastewater applications. The filter uses a nominal 30" deep media bed comprised of individual 1.25" diameter compressible synthetic fiber spheres, and achieves a high rate of solids removal down to 4 microns. The total porosity of the filter bed can be mechanically altered to suit influent characteristics by mechanically compressing the media. The filters are available sizes from 2.25 to 64 ft2 with flows ranging from 0.10 mgd to 2.8 mgd at a loading rate of 30 gpm/ft2. Schreiber LLC, Trussville, AL, 205-655-7466, www.schreiberwater.com

Filtration systemsOrival now provides complete water filtration systems designed for specific municipal and industrial applications. These systems include filters, manifold, valves and control. The ORG and OR series of automatic self-cleaning filters are designed to withstand the day-in and day-out rigors of POTWs. A wide range of filters are available from ¾" to 24" and filtration degrees from 5 to 3000 microns. Many of the company's filter models demonstrate low pressure loss, occupy minimal footprint, use only a few gallons of water for cleaning and need no electrical power to operate their cleaning mechanism; thus requiring less energy than conventional treatment methods. Orival Inc., 800-567-6797, www.orival.com

Cartridge filtersHurricane filters from Harmsco Filtration separate dense solids prior to cartridge filtration for extended filter life, increased dirt holding capacity and reduced maintenance costs. Components include an outer chamber for particle separation, inner chamber for cartridge filtration, and built-in drain for purge, if required. Deep angled pleats are directed toward rotational flow for increased dirt holding capacity. The rational flow improves the filter's performance. The filter uses a single "jumbo" cartridge design to simplify installation and maintenance. Harmsco Filtration Products, 800-327-3248, www.harmsco.com

Microfilter

The WesTech SuperDisc™ is an efficient microfilter provided in either stand-alone stainless steel tanks or forFiltration systems

A new subsidiary of Fairmount Minerals Ltd., Fairmount Water Solutions launched in February as a supplier ofiSep™ ultrafiltration (UF) membranes from TriSep were designed specifically for some of the most difficult and aggressive wastewater applications. Their key design feature is the integration of the UF membrane and process tank into a single module. The encapsulated membrane design allows for frequent draining, reducing fouling as all solids are easily purged from the system. Coupled with an efficient membrane air scour and vacuum pressure design, the system is able to operate at higher flux rates than conventional submerged membrane designs. TriSep Corp., Goleta, CA, 805-964-8003, www.trisep.com

Cloth media filterFluidyne has introduced a line of compact cloth media tertiary filtration systems that use patented gravity flow hydraulics and unique cloth media technology to eliminate mechanical wear items including pumps, drive motors, chain gears, backwash/sludge manifolds, and other mechanical moving parts. Fluidyne Fixed Plate (FFP™) Cloth media filters are suited for municipalities, residential developments, and industrial applications that require effluent tertiary filtration to meet tough discharge standards. The systems use a combination of differential head and a series of simple open-close pneumatic valves to provide tertiary wastewater filtration & backwash in compact, stainless steel packages. Fluidyne Corp., Cedar Falls, IA, 319-266-9967, www.fluidynecorp.com

Disc filterThe woven polyester pleated panel design of the Forty-X™ disc filter from Siemens Water Technologies provides increased treatment capacity and an ultimate barrier for suspended solids in tertiary treatment processes. The pleated media design increases the true cloth area available for filtration by 40% over flat panel designs. This assures a more sustainable operation in terms of throughput, better feed distribution and fewer backwash cycles. Additional extras include a trash-tolerant filter panel housing designed to prevent entrapment and accumulation of inorganic material, water pressure-assisted seals and wind-safe sliding covers to facilitate accessibility and maintenance. Siemens Water Technologies, 724-772-1402, www.siemens.com/weftec

MBR moduleThe Toray "Membray" submerged flat sheet membrane bioreactor module, when used as a component of an MBR system, effectively removes suspended solids from activated sludge. The microfiltration module in a plate-and-frame configuration consists of flat sheet PVDF membranes that are cast on a polyester, non-woven fabric as the base layer. This combination of materials gives the membrane improved physical strength and chemical stability. The module can be submerged directly into an activated sludge tank for combining biological treatment and membrane separation. It eliminates the secondary sedimentation process and reduces the activated sludge tank size. Toray Membrane USA Inc., Poway, CA, 858-218-1518, www.toraywater.com

Past IWW Issues