Case Studies

System Treats Complex Wastewater

By Terrence Vernig and John Meidl

A chemical manufacturer has ended its search for a wastewater treatment technology that meets its discharge requirements and handles wide swings in volume and concentration. Synthetech recently installed a PACT (powder activated carbon treatment) system that has met and exceeded its treatment goals.

Synthetech, Inc. of Albany, OR., produces peptide building blocks and specialty amino acids that are globally distributed to major pharmaceutical companies. The batch production uses a wide range of chemicals and results in a waste effluent that correspondingly fluctuates in volume, concentration and variety of contaminants.

Characterizing the Wastewater

Synthetech's wastewater combines non-process and process streams. The majority of the wastewater (non-process) is generated by wash and rinsing activities. The non-process stream contains medium to low organics and trace concentrations of regulated contaminants. The process wastewater stream, however, contains very high COD, Total Dissolved Solids (TDS) and other organic contaminants, and in the past has required off-site treatment at significant cost.

Setting Treatment Goals

Synthetech wanted its wastewater management to reflect its corporate philosophy of being a good citizen in its community and the environment while still minimizing costs. The company aimed to treat and control all waste on site to the greatest extent possible. This would require a treatment technology with flexibility to handle fluctuating volumes, varying contaminants and concentrations.

Tweaking the System

Synthetech eventually settled on a PACT® (powdered activated carbon treatment) system as most likely to meet its treatment goals. USFilter developed and tested a bench-scale PACT system for treating Synthetech waste in mid-2000.

The system later installed at the company is a factory built sequencing batch reactor (SBR) unit consisting of an aeration/settling tank, aeration blower, air distribution system, and delivery systems. It can handle a waste stream of approximately 3500 gal. of non-process water and 3500 gal. of process water and up to 380 lbs./day COD and a maximum load of 750 lbs./day.

The system treats the wastewater using powdered activated carbon combined with microorganisms in a water matrix. Diffused air ensures that the mixture remains homogeneous and the bugs receive sufficient oxygen. The activated carbon initially adsorbs much of the VOCs and other organics, and provides a substrate for the microorganisms.

The process stream was so high in TDS that even when blended with the non-process stream, it affected the biological ammonia removal. USFilter recommended using a small evaporation system to effectively reduce the TDS in the process stream. Only the resulting evaporate is sent to the PACT system for polishing treatment.

Since start-up in late September 2001, Synthetech's PACT system has met or performed better than the planned objectives. Levels of VOCs have been dramatically reduced. Effluent treatment requirements are being met or exceeded. BOD and TSS are maintained at levels that allow Synthetech to stay on track with sewer discharge rates.

About the Authors:

Terrence Vernig is the Environmental, Health and Safety Manager for Synthetech, Albany, OR. John Meidl is the PACT® Systems Product Manager for USFilter's Zimpro Products, Rothschild, WI. For more details on this installation visit www.waterworld.com and search for "Synthetech" in articles.

Continuous Resin Process Removes DOCs

The Water Corporation of Western Australia is building the world's first large scale MIEX® plant at the Wanneroo groundwater treatment plant. Two years of pilot testing have shown that this ion exchange process effectively removed dissolved organic carbon (DOC), a precursor of disinfection by-products (DBPs).

The pilot trials and laboratory results indicate that the MIEX® Process, and alum coagulation, or other chemical coagulation, complement each other, regardless of process order. For the raw water at the Wanneroo facility, the MIEX process favored the lower molecular weight fraction of DOC, while alum coagulation removed the larger molecular weight DOC components.

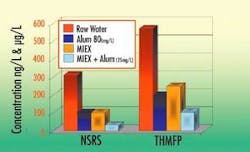

Enhanced coagulation alone could not match the reductions in DOC, non-sulfide reduced sulfur (NSRS) and Trihalomethane formation potential (THMFP) that MIEX treatment, together with enhanced coagulation, achieved. The graph compares the reductions in THMFP and NSRS achieved with MIEX treatment alone, enhanced coagulation alone, and MIEX treatment combined with alum coagulation.

The new process differs from conventional ion exchange technology in that the ion exchange step occurs continuously, while the regeneration step is performed in a batch operation. This allows steady state conditions to be maintained in the ion exchange area of the process.

The MIEX resin particles are smaller than conventional ion exchange resins. Following contact with the raw water, a magnetic component within the resin matrix allows the particles to form larger agglomerates that settle out faster.

The resin and raw water mix in the two 105,670 gal. concrete contactors and require only a minimal contact time of 10 minutes, even at full flow rate. Plant operators can adjust the resin concentration in the contactors to suit raw water quality and plant flow.

The resin and raw water mixture flows from the contactors to six concrete hopper-bottomed settlers. The gentle flow conditions allow the magnetic forces of attraction between the resin particles to form agglomerates, which settle out. The MIEX treated water rejoins the existing conventional treatment flow upstream of the plant clarifiers. The resin slurry either returns back to the first contactor, or is diverted for regeneration using 12% brine solution.

Black and Veatch, Australia, is the contractor for the new resin plant, which is being retrofitted at the Wanneroo groundwater treatment plant. The full-scale MIEX train will have a capacity of 30 MGD.