• Coolant production proves efficient, ecological with low-pressure-drop valve and well-designed site layout

Using river water makes production of coolant for air-conditioning both efficient and ecological. End-use applications include industrial cooling distribution networks and decentralized air conditioning systems for office buildings, hotels and museums.In the coolant production cycle, large volumes of river water must pass through the heat exchanger/chiller. With these large volumes, it’s essential to keep the pressure drop low and efficiency high. To do this, equipment selection and system layout must be made carefully to create the lowest resistance possible.

Previously, similar types of coolant production systems utilized mechanical check valves with moving parts that typically result in high maintenance costs. These types of valves also have higher pressure loss than desired. For a new installation at a cooling production facility in France, the goal for the project was to eliminate these problems and find a solution that would provide quiet, smooth operation with minimal maintenance. The installation would include pipes, pumps and heat exchangers to produce coolant for air-conditioning of buildings such as hotels and museums.

The Stop Silent® Check Valve from Lasso Technik Inc. was chosen for this plant as the most suitable valve for the application due, in part, to its unique cone shape design and ability to be custom built in accordance with the installation’s flow characteristics to produce a low pressure drop. Before arriving at this conclusion, different valves were considered, among them disc check valves. But there was just one able to achieve the very low pressure drop and a smooth closing demanded for the installation. The design of the Stop Silent multi-cone valve was made accordingly.

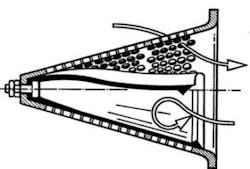

The Lasso Technik check valve is constructed with no movable mechanical parts and consists of only two components – a perforated stainless steel cone and a rubber membrane. When the valve is in the open position, the diaphragm deflects inward (see Figure 1, upper half). This allows passage of the liquid with very little pressure loss. Upon closing (see Figure 1, lower half), there’s a backpressure condition and the diaphragm resumes its relaxed position, covering all apertures in the cone and creating tight shut-off.

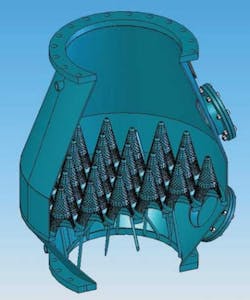

Challenges integral to installation success included optimal positioning of the cones to secure the lowest pressure drop possible and use of pumps that require less power. To accomplish this, the body shape of the valve was custom-designed to optimize flow characteristics and six DN600 multi-cone Stop-Silent Valves were installed (see Figure 2). Each multi-cone valve consisted of the valve body and 42 single valves (cones and diaphragm) inside (see Figure 3a & 3b). The body was welded together and covered with Epoxy coating (Nylon may also be used), producing excellent flow rates. The system performance includes an operating pressure of 44 psi (3 bar), operating temperature range of 5°C-28°C (41°F to 82°F), and speeds of 13,860 GPM (875 L/sec).

Implementation of this valve resulted in a pressure drop of 1.3 psi (0.09 Bar). Its cone design combined with an optimal site layout resulted in very little pressure drop to the system, achieving one of the major goals for the installation. With no moving parts to wear, maintenance-free service for up to 10 years was also achieved. And the valve eliminated water hammer and associated problems, providing near noise-free operation along with an ability to function simultaneously as a filter.

Conclusion

Results of the system installation were extremely satisfactory. No special training was required other than the installation instructions and customer’s expectations were completely fulfilled. Judging from this installation success, the move away from using mechanical check valves in the production of coolant will undoubtedly migrate to Lasso’s cone-style Stop-Silent Valve for greater efficiency.

These multi-cone valves offer solutions for backflow prevention in a variety of system types, and are always just one component in an entire system consisting of tubes, pumps, and heat exchangers, etc. They’re mostly used in piping systems with large diameters and large volumes – for example in water distribution, cooling systems and desalination plants. This example shows one possible application of Stop-Silent valves.

About the Author: Daniel Rohrer has been CEO of Lasso Technik Inc., of Basel, Switzerland, since 1994. The company’s U.S. distributor is Great Western Supply Co. of Houston, TX. Contact: 713-681-4786, [email protected] or www.stopsilent.com