Green Power

• Innovative water treatment design helps Midwest power station go green with packaged MF/RO system that cuts chemical discharges into manmade lake from which it draws cooling & boiler feed water while, improving reliability and reducing costs.

Reducing the footprint and the height was important as it allowed the system to be housed in a container, which could fit into the power plant’s limited space.

The Ameren Coffeen Power Station in Coffeen, IL, draws its water from a man-made 1,100-acre lake, which also boasts more than 20 species of fish and provides recreation for anglers, boaters, campers and hunters. The lake’s watershed has a relatively small amount of land area. The power station utilizes the lake for condenser cooling as well as makeup for boiler feed water. As a result, the water component of the ecosystem is essentially a large closed-loop system. Seasonally, the lake level can vary significantly. Particularly challenging are long, dry, hot summers, which lower the lake level and result in higher concentrations of dissolved solids.

Thus, when plant officials wanted to replace the facility’s aging water treatment system, they specifically chose technology to minimize the amount of regeneration chemicals discharged to the lake. In doing so, they were able to improve water quality in the lake and reduce acid and caustic usage and handling. The technology also had to be able to handle turbidity spikes and total organic carbon (TOC) levels in the lake water as well as silica and sodium levels. And the plant needed a highly reliable system with maximum uptime that produced the required quality and quantity of water and reduced plant costs and maintenance time. The solution was a new, innovative, containerized system design using microfiltration (MF) and high flow rate reverse osmosis (RO) technology.

The Treatment Equipment

To meet Ameren’s need for treated water in the interim before a long-term system could be designed, built, installed and started up, Siemens Water Technologies deployed a mobile water treatment system to the site. During this time, Siemens also would build a more “permanent” containerized system to replace both the old treatment system and temporary mobile system.

The temporary mobile system, deployed to the site in January 2008, included a mobile pretreatment trailer consisting of duo-media; two combo RO trailers (which contain multimedia filtration and RO); one mobile deionization (DI) trailer; and two skid-mounted FlexTrex® DI vessels for polishing product water after the DI trailer.

The long-term treatment system, which took six months to design and build, saw startup in February 2009. The flow path of this 300-gpm system is as follows: Lake water is first treated with sodium hypochlorite for disinfection, then flows through four MF systems and from there to a storage tank. After sodium bisulfite and anti-scalant injection, the water enters the first-pass RO system. The system also has the capability for sodium hydroxide to be injected into the water to convert carbon dioxide to bicarbonate for removal in the RO. A primary set of portable DI exchange vessels polishes the RO water, and a final set of portable DI exchange vessels further polishes the water to an even higher level of purity. Everything is tied together with a single controller via a remote I/O network. Siemens is operating the system under an operation and maintenance agreement.

Innovative Design

What makes the permanent system unique is the use of the technology in its containerized design. To meet the plant’s requirements, including a compact system that would take up minimal space, Siemens designed a new containerized 400 gpm MF system and containerized high flow rate RO system with a 300-gpm capacity.

“We were originally going to offer traditional technology in our design,” says Erik Lundgren, Siemens’ sales project engineer, “which was solid contact clarifiers followed by multimedia filters, two-pass RO and mixed-bed polishers. But the size and cost of this system was significant compared to what we could provide by incorporating MF technology into the design. MF is 30% smaller and 40% less expensive.”

Another benefit of the system is its skid-mounted design, which allows easy installation vs. having to construct steel or concrete clarifiers onsite and excavating for a conical floor. This reduced the construction schedule and onsite risks.

Reducing the footprint and the height was important as it allowed the system to be housed in a container, which could fit into the power plant’s limited space, and eliminated the need to build a separate building to house the equipment.

All three ROs are housed in a single trailer/container along with interconnecting piping, control panel, power distribution panel, lights and heaters. Pictured, RO skid and control panel.

Three RO systems are arranged in a two-pass configuration. All three ROs are housed in a single trailer/container along with interconnecting piping, control panel, power distribution panel, lights and heaters. This trailer includes the main control panel that ties the equipment together via a remote I/O network.

On-line silica and conductivity analyzers automatically monitor product water quality. The system starts up and shuts down automatically, based on the customer’s purified water storage tank level and is equipped with a telecommunication system that calls the Siemens’ technician with alarms.

Results

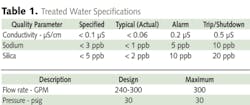

During the six months the system has been in operation, it has operated reliably with minimal downtime. Ameren has saved operating costs by reducing chemical usage. The system has exceeded product water specifications, as shown in Table 1. The amount of chemicals discharged to the lake was reduced by about 35%, and plant maintenance has been reduced by approximately 3,000 man-hours per year.

The system’s skid-mounted design allowed for easy installation and reduced the construction schedule as well as onsite risks.

The system is owned by Siemens and operated and maintained by personnel from the local Siemens’ branch office. The quantity and quality of the water is guaranteed for the life of the contract. Pricing to the customer includes a base rate at a fixed cost with a variable rate based on quantity.

Conclusion

Ameren is generally pleased with the performance of the equipment as well as service provided by Siemens. And the reduction of regeneration chemicals has benefited the lake.

About the Authors: Located in Hoffman Estates, IL, Charles McCloskey is the director of industrial and environmental services marketing for Siemens Water Technologies. Contact: 847-713-8468 or [email protected]

Based in Rockford, IL, Steve Lindvall is a senior project manager for services and products at Siemens Water Technologies. Contact: 815-921-8265 or [email protected]