MBR Aquaculture System Yields Clean Water, Recovers Valuable Resources

By Steven Summerfelt and Mark Sharrer

Membrane biological reactors (MBRs) provide water recirculating aquaculture systems (WRASs) with high-quality waste removal as well as the recovery of valuable resources including water, salt, alkalinity, heat, phosphorus, and protein, according to a recent study conducted by The Conservation Fund's Freshwater Institute.

Membrane biological reactors use activated sludge and a series of membranes to remove nitrogen, phosphorus, five-day biological oxygen demand, suspended solids, and heavy metals from the WRAS wastewater, leaving a particulate-free permeate suitable for reuse in fish culture systems. The process allows for nearly complete recovery of the wastewater stream.

The MBR was operated for the recovery of water, alkalinity, salts, phosphorus and protein contained in the highly concentrated wastewater

The study's authors also found MBRs provide other advantages when coupled with a water recirculation aquaculture system. For example, they allow a fish farm to choose a location near inexpensive resources such as power, oxygen, and feed or close to its market. They also eliminate all or almost all wastewater discharge, leaving only a stabilized biosolid that may be suitable for composting or land application as a soil amendment.

While the MBR technology is expensive and has significant operating costs, the costs can be offset by the water, heat, salinity, and alkalinity recaptured through the process.

The study, conducted using an MBR at the Conservation Fund's Freshwater Institute in Shepherdstown, WV, was supported by a cooperative agreement with the United States Department of Agriculture – Agricultural Research Service. The researchers wanted to determine the capacity of an MBR to process WRAS flushing flows containing either normal or elevated levels of nitrogen and phosphorus, and secondarily to determine the concentration of heavy metals in the resulting permeate and biosolid.

The MBR was operated for the recovery of water, alkalinity, salts, phosphorus and protein contained in the highly concentrated wastewater that came from backwashing rotating microscreen drum filters used to filter particulates from the recirculating water in the system. Other biological filters convert the total ammonia nitrogen (TAN) excreted by fish into nitrate-nitrogen. The net result is a backwash of biosolids low in TAN and high in nitrate-nitrogen.

The study used backwash wastewater collected from a WRAS operated for rainbow trout loaded to the MBR as the control condition. Trout require a relatively high water flushing rate compared to some other fish grown in recirculating systems. To replicate the conditions of low flushing rate systems, the test condition in this study, appropriate proportions of sodium nitrate and granular anhydrous monopotassium phosphate were added to the wastewater entering the MBR to achieve an additional 100 mg/L nitrate-nitrogen and 3 mg/L phosphorus. Each condition was maintained for 21 days and replicated four times.

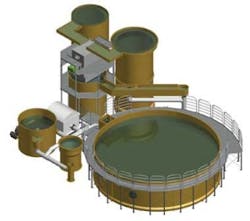

This schematic shows the commercial-scale water recirculating system used to produce trout, char, and salmon at the Freshwater Institute. A typical complete or full recirculation aquaculture system will contain one (or more) large growout tank (lower right) and tanks that continuously condition and filter the recirculating water. (schematic courtesy of Marine Biotech)

A consistent concentration of activated sludge is necessary for optimal MBR function. Because the biosolids that make up the sludge build up during treatment, some must be removed periodically in a process termed "biosolids wasting." As a result, a small amount of potentially reclaimable water is lost along with the wasted biosolids.

The research found little loss of reclaimable backwash due to activated sludge solids wasting and disposal. The MBR processed approximately 7.1 m3 of RAS backwash daily, and the activated sludge wasting rate was approximately 460 L/day. The resulting wastewater recovery rate was approximately 93.5 percent.

The MBR performed well in both the control and test. It removed 99.97 percent and 99.98 percent of the total suspended solids respectively. No difference in the carbonaceous biological oxygen demand removal was apparent, with 100 percent removal in both cases. The MBR also removed 98 percent of the nitrogen in both the control and test case. Under control conditions total nitrogen entering the MBR was 86 ± 10 mg/L and under test conditions it was 185 mg/L. Total ammonia nitrogen and nitrate-nitrogen removal efficiencies were marginally reduced under test conditions, but the permeate concentrations were remarkably low at either nutrient loading condition.

Both the test and the control recovered alkalinity. Influent and effluent alkalinities were 259 ± 5 and 312 ± 10 respectively under control conditions. They were 281 ± 8 and 560 ± 19 respectively under test conditions. This represents complete recovery of alkalinity under control conditions, and enhanced recovery under test conditions, according to calculations based on the United States Environmental Protection Agency Nitrogen Control manual.

Water recirculating systems that use biological filters operated at low flushing rates quickly consume alkalinity, which requires the addition of sodium bicarbonate to maintain alkalinity concentrations above 100 mg/L as calcium carbonate. The alkalinity recovered in the permeate could replace the requirement for carbon supplementation in fish culture systems that use nitrification reactors to remove ammonia and operate at low make-up water rates.

In Freshwater Institute's circular tank RAS system, water is circulated around the tank and fish wastes spiral down to a central drain. Here Arctic Char swim against the tank's current. The constant exercise seems to increase fish health.

Tests conducted by outside laboratories found that the heavy metals found in the permeate were at levels similar to the levels found in the source water, a spring on the Freshwater Institute's property. In addition to entering the WRAS in the source water, metals accumulate in the waste stream as a result of feed additives and leaching from the metal parts of the recirculating system. The tests found that the levels in the biosolids were low enough that the biosolids could be composted or incorporated as a soil amendment.

The phosphorus captured by the activated sludge offers a way to reclaim this valuable resource. It can be used as a soil amendment in agriculture, potentially displacing fertilizers made from phosphate rock. The bacteria in the activated sludge take in this nutrient in excess when subjected to aerobic and anaerobic conditions. In both the control and test case, the MBR produced exceptional phosphorus removal efficiency. The permeate total phosphorus concentration was 0.10 ± 0.03 under test and 0.05 ±0.01 under control conditions.

The microorganisms in the MBR also captured proteins. The sludge contained 25.2 ± 2.9 percent on a dry-weight basis. This is a little lower than the desired content for a feed additive.

The reclaimed water, alkalinity, salt and heat are immediately valuable to production fish farms, offsetting the need for additives to condition the water. The biosecurity offered by the system and the flexibility in site selection also offer benefits that make MBR technology attractive. IWW

About the Authors: Dr. Steven T. Summerfelt, Professional Engineer, is Director of Aquaculture Systems Research, The Conservation Fund's Freshwater Institute. His research focuses on water treatment processes and on optimization of fish production He has worked on the design of several large private and public fish-farms and with state and federal agencies on the evaluation and design of hatchery water supply, production system, and effluent treatment systems. Mark Sharrer is a Senior Research Associate. He received his Bachelors Degree in Fisheries Science from Virginia Tech. Sharrer's experience includes work at the Virginia Tech Horseshoe Crab Research Center.

Past IWW Issues