Nanotechnology & Nanoscale Materials: The Good, the Bad, and the Ugly

by Jeffrey J. Keller, P.E.

Nano what?

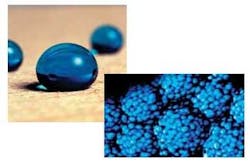

Worldwide, materials manufactured at this tiny scale are becoming a huge business. Development and use of nano-scale materials and nanotechnology was a $42-billion industry in 2005, and is projected to grow to $1 trillion or beyond by 2015. Products are being designed, tested, and sold today that make use of nano-properties, including common consumer items such as sunscreen, lotion, shampoo and cosmetics. More commonly discussed applications include electronics with sharply reduced size, as well as materials with tailor-made physical properties (such as weight, strength, etc.) unavailable with their “macro” counterparts (see Figure 1). Growth of the nanotechnology and nanomaterials industry poses major challenges for the water/wastewater industry. While it creates a new class of contaminants to understand and prepare for, proper application of nanotechnology may produce products beneficial to the industry.

The Good

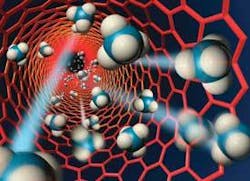

Nanotechnology and nanoscale materials may provide improved treatment performance, new treatment methods, and cheaper and more failure-resistant materials and components for the water and wastewater industry. Chief among these are use of filters with pore sizes on the order of 1-2 nm, fabricated with nanoscale materials that produce pores smooth down to the molecular level. These super-smooth pores could exhibit significantly lower frictional resistance, and thus possess flux properties many times larger than conventional filters. Nanomembranes (see Figure 3) also are being developed with special functional groups to help reduce surface fouling, allowing for a larger flux over a longer time period compared to conventional membranes. Controls and sensors developed with nanotechnology may allow for accurate real-time detection of a variety of biological and chemical parameters not possible today. This could allow more efficient operation or possibly improve the level of treatment by optimizing reactor conditions on a real-time basis. Coating systems only a few mils thick and based on nanoscale materials could block corrosion in critical areas and provide thermal insulation for structures. Materials called carbon nanotubes, part of a group of molecules known as fullerenes, are expected to exhibit a strength 10 times that of steel at 1/6th the weight. Using these materials or others developed through nanotechnology may allow more cost effective design and construction of structures, or structures with configurations not possible with today’s material options. More recently, investigations into optimization of microbial fuel cells using anodes with nanoscale dimensions found dramatically increased energy yields, suggesting nanotechnology may be a key element in producing significant electrical power as a byproduct of biological treatment processes. Running a treatment system without significant demands on a local electric utility would certainly make this nanomaterial-based product attractive to industry.

The Bad

Early testing indicates some materials at the nanoscale may be of concern to water professionals, as they may exhibit toxic properties under certain exposures. Many can be made water soluble and absorbed into biological tissues. Early toxicology studies found evidence of toxic properties under both inhalation and injection exposure pathways for various nanoscale materials. Observed abilities of some nanoscale materials to migrate into human cells and possibly pass through the blood-brain barrier provides ample encouragement for the research community to develop a clearer understanding of this class of materials. Meanwhile, future large-scale manufacturing using nanoscale materials could result in potential workplace exposure or release of these materials into the environment. Workplace exposures are particularly lacking in data within professional journals focused on health and safety. Potential approaches to managing this issue include a stronger focus on waste minimization and pretreatment. This approach is particularly relevant to nanoscale materials, where reclamation would have significant economic value for particles that in some cases are worth more than their weight in gold! Technologies such as membrane filtration, absorption, electrostatic precipitation, or sequestration at the municipal WWTP may be able to remove nanoscale materials, but much more study is required before their safe management at an activated sludge plant is assured. Ironically, future treatment technologies to address them may be based on beneficial properties of these materials and nanotechnology.

The Ugly

The “ugly” side of all this are difficulties in quantifying the environmental toxicity of these materials. Understanding nanotoxicology is problematic due to the materials’ unique physical and chemical properties. They tend to exhibit very different properties compared to their macro-counterparts due primarily to their very small size. A greatly increased surface-area-to-volume ratio can create a material that reacts very differently and sometimes much more aggressively than otherwise expected. Nano-gold, for example is red instead of gold. Normally innocuous materials like carbon and Teflon have induced tissue damage and even death in lab animals. Nanomaterials in general appear to behave in ways contrary to our common sense understanding of everyday macro-materials. New approaches to toxicity studies and material classification schemes may be needed to properly assess the impact of this new class of compounds on human health and the environment. As suggested previously, one major hurdle to overcome is to establish an understanding that the macro- and nanoscale versions of the same material are often very different and shouldn’t be classified the same way. In many cases, nanoscale materials should be considered new materials even if they have familiar names.

Beyond technical concerns, public awareness and successful communication is also a key element of addressing risks involved with research and use of nanoscale materials and nanotechnology. As research results become available to the public, and as products utilizing nanoscale materials are released to consumers, it will be important to foster a fundamental understanding of nanoscale science, materials and technology. In a 2006 poll, over three-quarters of U.S. residents indicated they had heard nothing or little about nanotechnology (see Figure 5). A public education program could help give the public a basic understanding of potential benefits and risks of nanoscale materials, allowing them to make more informed decisions regarding consumer behavior and public funding for research. This effort must be framed with care, as the parties involved (industry, academia and government) must act in an unbiased fashion, neither directly promoting nor acting unnecessarily critical of these new materials and technologies. Only by receiving information in a relevant, concise and relatively unbiased format will the public be able to act as a rational player in development of this new field.

Conclusion

A number of actions exist that could be taken by both public and private sectors to best address issues presenting themselves as this new industry emerges. Investment in toxicological studies and pretreatment technologies may help limit release of nanoscale materials into the environment, and to predict consequences of such releases. Proper selection and utilization of innovative nanotechnologies could greatly improve unit processes, materials and control systems, but the greatest positive impact on the water and wastewater industry may not be seen until this technology is allowed to mature.

About the Author: Jeff Keller is a senior process engineer with Kansas City, MO, engineering consultant firm Burns & McDonnell. The above article is based on a presentation he gave in August 2007 at the Water Environment Federation’s Contaminants of Emerging Concern event held jointly with Industrial Water Quality Conference in Providence, RI.

Figure 5. Percent of U.S. adults who knew very little or nothing about nanomaterials or nanotechnology.