Product Showcase

Metering pump

Iwaki America’s LKN series motor-driven, mechanically actuated diaphragm metering pump features a 114 GPH maximum capacity and 225 PSI maximum pressure. Available in a range of materials, the LKN series is suitable for almost any chemical injection or metering application. Although new to North and South American markets, the series has been marketed in Asia and Europe for over 40 years. Iwaki America Inc., Holliston, MA, 508-429-1440, www.iwakiamerica.com

Protective shelters

From a division of CDR Systems Group, AegisTM Protective Shelters are lightweight, pre-assembled, fiberglass enclosures designed to hold mechanical equipment and/or supplies, including chlorination equipment, pumps, pump stations, monitoring equipment, other systems and inventory. Standard features include non-corrosive fiberglass construction, UV resistant finish, lockable access and weather resistant hardware. Aegis Protective Shelters, Jacksonville FL, 888-852-3447, http://aegisshelters.com

Self-cleaning filters

Schroeder Industries’ SC automatic self-cleaning filter line is used to remove solid contamination from process fluids and to protect the integrity of high grade components that depend on low-viscosity, water or water based lubricants. The filter is ideal for applications where fluid flow cannot be interrupted and must be maintained at an acceptable cleanliness level. It achieves flow rates up to 33,000 gpm with ANSI flange sizes ranging of 2-36”. Superior removal of contamination particles is accomplished with slotted tube filter elements of 50-3,000 μm and super mesh filter elements with 25-40 μm. Schroeder Industries, Leetsdale, PA, 724-318-1100, www.schroederindustries.com

Screening system

To remove and clean larger flows of wastewater, the new Auger Monster XE screening system offers substantial improvements, including the new pivoted auger design that allows the screening trough to pivot and swivel out of the channel for inspection. Other enhancements include: increased removal efficiency with a 35º inclined auger; dual ultrasonic level detectors run the system only when needed to save electricity; a “fail-safe” mode ensures continuous operation - even when the electronics are disabled; and all frames and covers are made from polished, passivated stainless steel. JWC Environmental, Costa Mesa, CA, 800-331-2277, www.jwce.com

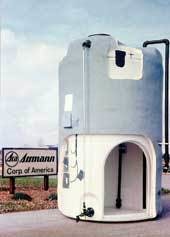

Double-wall tanks

Cylindrical double-wall tanks from Assmann Corp. eliminate chemical spills and prevent dome collapse without expense of lined concrete containment. The molding process provides a heavier-top sidewall and dome to prevent collapse, while the primary inner tank and a secondary locked-on outer tank ensure against chemical spills. Constructed of molded high-density crosslinked polyethylene or FDA compliant linear polyethylene, the tanks provide an outer shell containment that exceeds EPA standards at 120% of primary tank capacities. Assmann Corp. of America, Garrett, IN, 888-357-3181, www.assmann-usa.com

Hollow fiber UF system

Miller-Leaman’s UF Membrane System removes suspended particulate, bacteria, colloidal, and high molecular-weight contaminants from source water. Ideal for pre-filtration of RO membranes, target industries/applications include wastewater, reuse water, municipal, textiles, pulp & paper, pharmaceutical, plastics, and electronics. Filtering between 0.1 to 0.01 microns, the system provides high quality effluent water, removing all TSS with more than a 95% recovery ratio and producing output water turbidity of less than 0.4 NTU. Miller-Leaman Inc., Daytona Beach, FL, 800-881-0320, www.millerleaman.com

Liquid filtration rental

BakerCorp’s new 10K Specialty Media System enables more flexibility for filtration industry professionals. This new filtration system features dual vessels, containing up to 10,000 lbs (10K) of media per vessel, an integrated lead-lag pipe rack with backwash capability and a safety work platform conveniently mounted on a compact skid. It was designed to achieve higher flow rates while providing a more cost-effective, labor-saving alternative to traditional equipment commonly used for liquid filtration applications. BakerCorp, Seal Beach, CA, 562-430-6262, www.bakercorp.com

Thermal mass flowmeter

The new ST50 Flow Meter Series is now comes with a +1% accuracy configuration for line sizes of 2-24” and is suitable for applications in air, compressed air, HVAC and process gases, including nitrogen. It features FCI’s thermal dispersion mass flow sensing technology, which provides direct flow measurement for higher accuracy. Its design also provides built-in temperature compensation for reliable measurement over a wide temperature range with almost no pressure-drop. Fluid Components International, San Marcos, CA, 800-854-1993, www.fluidcomponents.com

Dissolved air flotation

With capacities from 20-to-2000 gpm the RC Series Dissolved Air Flotation (DAF) system is a high built separator designed for high volume flow rates. It’s fabricated of stainless steel and engineered to handle a range of flow rates and pollution levels. The design provides for a large amount of effective surface area available for hydraulic loading capabilities relative to the footprint area required. The combination of corrugated plates, thickening techniques and skimmer design produces sludge with very high dry solids content. Siemens Water Technologies, Warrendale, PA, 866-926-8420, www.usfilter.com