Reuse: Alternate Water Sources Benefit Industries and Communities

Population growth, industrial expansions and recurrent drought as well as increasingly stringent and expensive-to-comply-with discharge regulations have left many industries and cities short of water. While new usable water supplies aren’t easily found, industries and municipalities are doing so by turning to advanced water treatment processes that incorporate integrated membrane systems. Such systems economically treat wastewater and produce high-quality product water for beneficial reuse.

The four highlighted installations in this article help illustrate how local industries and municipalities have worked together to employ advanced water treatment processes and successfully manage their entire water balance.

Down the Drain

Industries and communities often draw their freshwater from the same source. Once the water is used, it’s treated and discharged. Industries and communities both incur a significant and growing expense by treating the wastewater to meet stringent discharge regulations. The wastewater quality is frequently higher than that of the receiving body. Discharge from a wastewater treatment plant (WWTP) into surface water usually becomes an industrial or drinking water plant’s intake somewhere downstream. Similarly, wastewater that’s deep-well injected may eventually reach an aquifer and be pumped out for industrial and/or potable use. In both cases, money is spent to treat the wastewater for disposal.

Industries and communities that draw from a groundwater source can strain the aquifer and begin to deplete the source, eventually creating additional unforeseen problems due to land subsidence. In coastal communities, seawater worsens the problem by intruding into the freshwater aquifer and deteriorating the groundwater quality. Depletion and deterioration can lead to consumption restrictions and additional treatment costs. A balance between water users’ needs and the availability of water must be struck.

Achieving Balance

For years, the scarcity of and need for freshwater have spurred battles and legal debates between industry, agriculture and municipal “rights” for use. All of these uses are equally important to regional economies and communal well-being and, as a result, various conservation programs have been put in place to address the limited availability and distribution of water.

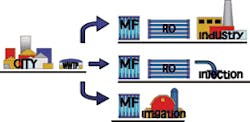

Original conservation attempts reclaimed municipal wastewater only for irrigation purposes. While this reduced the net intake of water and also justified the cost of treating additional wastewater, it did not address industrial needs. As technology was developed, tested and ultimately implemented, the solution became economically and ecologically obvious. Using low-pressure membrane filtration (MF) and reverse osmosis (RO) to further treat municipal wastewater made it possible to supply water of various qualities for industrial, recreational and groundwater replenishment needs.

Integrated Technology

In reuse applications, the feed water is often secondary effluent (biologically treated municipal wastewater) that requires further treatment prior to reuse. Reverse osmosis (RO) often is used to achieve the purity required for industrial, potable and other uses. RO membranes are well suited for removing dissolved solids but are adversely affected by suspended solids, colloidal matter, organics and bacteria. Membrane fouling from these constituents is a major reason for RO system failure. Membrane replacement comprises approximately 25% of an RO system’s annual operating cost. Appropriate pretreatment is critical to RO systems’ long-term, stable performance.

Microfiltration (MF) is a low-pressure membrane process specifically designed to remove the suspended matter that cause RO membrane fouling. MF as pretreatment can significantly reduce RO membrane fouling and provide a stable, predictable performance that other conventional pretreatment technologies cannot match. With an MF system’s effluent providing a silt density index (SDI) of less than 3, RO fluxes have been observed at 20% higher than with conventional pretreatment technologies that struggle to maintain an SDI of 5 or less. The higher flux translates into a smaller RO system.

Membranes comprise about 50% of an RO system’s capital cost. Additionally, when MF is used, RO membranes require less frequent cleaning. For instance, if an RO cleaning were occurring once a month, it is possible to extend this cleaning to once a year by adding MF as pretreatment.

As shown in Figure 2, municipal wastewater is treated by membranes for a variety of uses including industrial process water, irrigation and deep-well injection for coastal communities or other areas where groundwater requires replenishment.

System Examples

There are many water recycling and reclamation facilities around the globe. The examples below show how integrated membrane systems have been applied to secondary sewage to benefit both local industries and communities. Although the specific drivers differ by project, they all hinge on a partnership to create a sustainable water supply for current and future economic development.

• Hawaii - A reclamation facility in Honouliuli, commissioned in August 2000, produces 12 million gallons per day (mgd) of beneficial reuse water from secondary effluent previously discharged into the Pacific Ocean. The process generates two grades of water. One grade is extremely high in purity and is sold to power and petrochemical refining companies; the other is purchased by the city for irrigation purposes. As a result, the amount of available water for residential needs has increased by 3 mgd.

• California - West Basin Municipal Water District constructed a 38-mgd recycling facility to provide various grades of water, based on its customers’ needs. MF is used to treat wastewater from the city of Los Angeles’ WWTP before it’s sold for irrigation to nearby parks, cemeteries and golf courses. RO is used to further treat water that’s sold to local refineries. The remainder is injected into the ground to offset seawater intrusion into the aquifer.

• Australia - Eraring Power Station’s chemists and management redirected the city’s sewage treatment plant secondary effluent from the ocean, as planned, to an advanced water treatment facility. A 2-mgd integrated membrane system consisting of MF followed by RO provides high-quality water for the power plant. In the process, the local water authority saved over US$4 million through deferral of infrastructure required to upgrade its wastewater treatment system and supplement the region’s potable water supply. Eraring Power has saved over US$690,000 annually in operating costs.

• Singapore - In December 2002, the Public Utilities Board commissioned the 16-mgd Kranji Water Reclamation Plant. The plant combines low-pressure MF with RO and ultraviolet light disinfection to produce high-purity water from secondary effluent. This reclaimed water supplements Singapore’s water supply for semiconductor manufacturing while ensuring a sustainable water supply for the city-state’s future development.

Conclusion

Advanced water treatment processes benefit industries and communities by utilizing alternate water sources that provide sustainable water supplies for current and future economic development. Reclamation facilities that incorporate RO are becoming more common due to the high-quality water for industrial applications, advancements in the technology and sharply lower production costs that have made it more affordable. Use of low-pressure membranes as pretreatment to RO systems has resulted in integrated membrane systems that have become more reliable, economical and easier to operate and maintain than earlier systems with conventional pretreatment.

About the Author: Glen Sundstrom is the industrial market manager at USFilter Memcor Products, a part of Siemens Water Technologies, in Rockford, IL. With a bachelor’s degree in chemical engineering from the University of Wisconsin-Madison, he has worked for USFilter in industrial water treatment applications for 21 years. Contact: 815-921-8282 or [email protected].