Power Plant Co-Location Reduces Desalination Costs, Environmental Impacts

by Nikolay Voutchkov

Two key historical barriers for wider implementation of seawater desalination are water production costs and environmental impact of the plant concentrate. Both the economics of seawater desalination and desalination plant discharge impact on the environment could be improved significantly by co-location of membrane desalination plants with existing power generation stations.

A Joint Effort

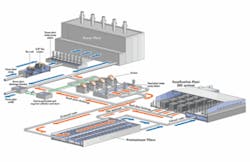

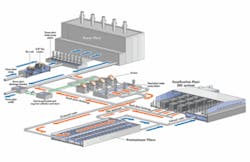

Co-location provides a direct connection of the membrane desalination plant intake and discharge facilities to the discharge outfall of an adjacently located once-through coastal power generation plant. This configuration allows using power plant cooling water as source water for the desalination plant and as blending water to reduce salinity of desalination plant concentrate prior to discharge to the ocean (see Figure 1).

Under typical operating conditions, seawater enters the power plant intake facilities and, after screening, is pumped through power plant condensers to cool them and thereby remove waste heat generated during electricity generation. Cooling water discharged from the condensers typically is 5-15°C warmer than the source ocean water and is usually conveyed to the ocean via a separate discharge outfall.

Under the co-location concept, the seawater desalination plant intake is connected to the power plant discharge canal to collect a portion of the cooling water for desalination. After the desalination plant source seawater is pretreated, it’s processed in a reverse osmosis (RO) membrane desalination system, which produces two key streams - low salinity permeate, which (after conditioning) is conveyed for potable water supply, and concentrate with a salinity typically two times higher than the source seawater. This concentrate is conveyed to the power plant discharge outfall downstream of the desalination plant intake connection.

Co-location with a power station in a large scale was first used by Poseidon Resources for the Tampa Bay Seawater Desalination Project, and since than has been considered for numerous plants worldwide, including several in California where 15 desalination projects are ongoing to serve future water needs. The intake and discharge of the Tampa Bay Seawater Desalination Plant are connected directly to the cooling water discharge outfalls of the Tampa Electric (TECO) Big Bend Power Station (see Figure 2).

Recognizing benefits of this co-location approach, the American Academy of Environmental Engineers recently awarded Poseidon Resources the 2006 Grand Prize for Excellence in Environmental Engineering in the Research category and the U.S. Patent Office granted it a patent in September 2005.

Necessary Conditions

For the co-location concept to be cost-effective enough to implement, the power plant cooling water discharge flow has to be larger than the desalination plant capacity and the power plant outfall length has to be adequate to avoid entraining and recirculation of concentrate into the desalination plant intake. Special consideration has to be given to the effect of the power plant operations on the discharge water quality, since this discharge provides intake source water for the desalination plant. Some older power generation plants - equipped with copper or nickel condenser tubes that exhibit significant corrosion - may not be suitable for co-location. Significant elevation of copper, nickel or iron in power plant discharge may render it unsuitable for use as source water for membrane seawater desalination plants because, if these metals occur in large quantity, they may cause irreversible fouling of membrane elements.

A Common Intake

Usually, coastal power plants with once-through cooling use large volumes of seawater. Because the power plant intake seawater has to pass through small diameter tubes (typically 7/8" or less) of the plant condensers to cool them, power plant discharge cooling water is already screened through bar racks and fine screens similar to those used at surface water intake desalination plants.

A desalination plant with the intake connected to the discharge outfall of a power plant usually doesn’t require construction of a separate intake structure, intake pipeline and screening facilities (bar-racks and coarse screens). Since the cost of a new surface water intake for a desalination plant is typically 5-20% of total plant construction costs, power plant co-location yields significant savings.

Sharing intake infrastructure also has environmental benefits because it avoids the need for new construction in the ocean and seashore area near the desalination plant. Building a separate new open intake structure and pipeline for the plant can cause significant disturbance of benthic marine organisms on the ocean floor. Use of intake beach wells instead of open intakes has similar negative environmental impact on these marine organisms during beach well construction.

Sharing Discharge

Under a co-location configuration, power plant discharge serves both as an intake and discharge to the desalination plant. Four key benefits stem from this arrangement: 1) it avoids construction of a separate desalination plant outfall structure, decreasing desalination costs by 5-20%; 2) salinity of the desalination plant discharge is reduced as a result of mixing and dilution of membrane concentrate with power plant discharge, which has seawater salinity; 3) because a portion of the discharge is converted to potable water, total quantity of the power plant thermal discharge is reduced, which lessens negative effects of the power plant thermal discharge on the aquatic environment; 4) blending of desalination plant and power plant discharges results in dissipation of both salinity and thermal discharges.

Other Cost Reductions

One key additional advantage of co-location is the overall reduction of desalination plant power demand and associated costs of water production as a result of warmer source water. Source water of the RO plant is typically 5-15°C higher than the temperature of ambient ocean water. This is of significant benefit, especially for desalination plants with cold source seawater (such as ocean water in Northern California), because the RO membrane separation of 10°C of warmer seawater requires about 5-8% lower feed pressure, and, therefore, proportionally lower energy use for seawater desalination. Since power costs are about 20-40% of total costs for production of desalinated water, use of warmer source water has a measurable beneficial effect on overall water production costs.

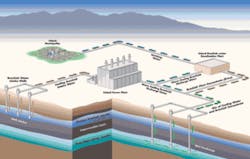

Inland Plant Co-location

Although the co-location approach originated as a seawater desalination application for coastal power plants, this concept can be implemented at inland power generation plants using brackish water collected from wells for once-through cooling. Under such conditions, intake of an inland brackish water desalination plant located adjacent to the power plant could be connected to the power plant discharge to use power plant cooling water as source water for the brackish water desalination plant. Brine from the desalination plant would then be returned into the same discharge line, mixed with the remainder of the cooling water and discharged through the power plant injection wells (see Figure 3). This approach avoids the need and costs to construct separate intake and discharge wells for the desalination plant.

Conclusion

Co-location of desalination plants with power generation stations may yield measurable improvement in the economics of seawater and brackish water desalination and offer cost-reduction advantages as a result of use of shared intake and discharge facilities, and reduced desalination power costs. In addition, co-location may provide environmental benefits for both the power station and desalination plant due to accelerated dissipation of thermal and saline discharges - as well as reduced impact on the marine benthic and seashore habitats - by avoiding the construction of new intake and outfall structures and pipelines in the sea.

About the Author: Nikolay Voutchkov is senior vice president of technical services for Poseidon Resources Corp., of Stamford, CT. Contact: 203-327-7740, ext. 126, or [email protected]