Biomimetic Membranes: Nature Inspires Next Generation of Water Filtration Technology

By Jeff Gunderson

In the novel field of biomimicry, nature's ingenuity is imitated in the design and engineering of innovations that seek to solve challenging problems. The core theory of biomimicry holds that concepts found in nature with inherent, well-adapted characteristics can provide meaningful inspiration in the creation of breakthrough technologies and solutions.

It's this mode of thinking that has given rise to the research and advancement of biomimetic membranes, an innovation in water filtration technology that aims to replicate a natural process occurring at the cell level -- specifically, the highly-selective and efficient transport of water molecules across a cell membrane.

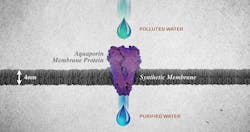

A promising approach to this concept is based on the use of aquaporin molecules, a naturally-existing protein that serves the important function of maintaining osmoregulation in living organisms by facilitating water transport through cell walls.

The key advantage of the aquaporin molecule is the ability to restrict the passage of contaminants including bacteria, viruses, minerals, proteins, DNA, dissolved gases, salts, detergents, and even protons without encumbering the passage of water, said Frost & Sullivan technical insights industry analyst Jennifer Tan. "Small molecules such as urea and boric acid -- which are inefficiently removed by conventional membranes -- are even rejected," she said.

For the past several years, a number of research efforts have been underway in an attempt to utilize aquaporins -- or replicate the protein's functionality -- in the development of a new biomimetic membrane technology. According to proponents, biomimetic membranes hold considerable promise as a low-energy option and a more effective alternative to desalination, industrial water treatment and other water purification applications.

One company, Copenhagen, Denmark-based Aquaporin, has spent the greater part of the last 10 years developing a biomimetic membrane that integrates aquaporin proteins into a thin film layer supported by a porous membrane.

Aquaporin CEO and founder Peter Holme Jensen said the foundation for his company's patented Aquaporin Inside™ technology is based on scientist Peter Agre's original discovery of aquaporins in living cells -- for which he received the 2003 Nobel Prize -- and also research conducted by colleague Morten Østergaard Jensen, who was the first in the world to develop computer simulations showing how water is transported through aquaporin water channels.

"After seeing how the proteins worked in a computer model, we sought to apply this functionality in an industrial setting," said Aquaporin's Jensen. "This truly shows how science can lead to commercial ideas."

According to Jensen, the use of actual aquaporins presents a very attractive proposition based on the protein's incredible selectivity for transporting pure water molecules and also because of the hydrophobic nature of the aquaporin's water channel. "The aquaporin protein essentially lures water molecules into its channel but because of the hydrophobic environment, the molecules then shoot through to the other side," he said. "This results in highly efficient water transport -- even though water molecules can only pass through the protein channel in single file, up to one billion are transported every second."

The Aquaporin Inside™ technology is essentially a thin film coating that hosts aquaporin proteins in an environment that retains the molecules' natural activity of moving water molecules. The coating can be applied to both flat-sheet membranes and hollow fiber modules.

The company's primary market focus includes industrial water treatment, treatment of difficult wastewater streams and other niche segments. Currently, Aquaporin is scaling up its technology and has begun automated roll-to-roll production. "We have started testing with future customers around the world and expect to be selling membrane modules in the market this year," Jensen said.

Also in Denmark, Applied Biomimetic is another company developing a biomimetic membrane technology that is based on isolating and mass-producing aquaporin proteins that are then embedded into a polymer matrix.

The design approach to Applied Biomimetic's technology involves controlling the amount of integrated aquaporin proteins in order to design membranes to a specific permeability and a desired capacity, according to Steen Søndergaard Nissen, president & CEO of Applied Biomimetic.

"Desalination represents the most ambitious filtration goal, but with less ambitious purpose in mind, we believe it's possible to design a membrane that is very suitable for wastewater treatment and handling various industry process streams," Nissen said.

Nissen also believes that a successful aquaporin-based membrane design would bring improved flux rates as compared to already existing membranes. "A biomimetic membrane that improves the flux by two to three times, or possibly more, would represent an attractive proposition to industry -- depending on the specific application," he said.

Research on the advancement of aquaporin-embedded biomimetic membranes is also taking shape at Edmonton, Alberta-based Ingenuity Lab where Dr. Carlo Montemagno and a team of researchers are working on perfecting a robust membrane system that could stabilize aquaporin molecules in a way that would allow for use in commercial water treatment applications.

"Our focus is geared toward creating a stable membrane structure that will withstand a broad range of temperatures -- where the molecules would continue to function in an industrially-relevant environment," Montemagno said. "The goal of this effort is to develop a platform technology that is both economically manufacturable and protects the aquaporin molecules from mechanical and chemical stresses while maintaining functionality."

Montemagno, who has been working since the late 1990s on developing engineered systems that utilize the building blocks of nature, said the biggest challenge in biomimetic membrane fabrication is related to scaling. "It's not an issue of whether or not the technology works but how to manufacture membranes that intrinsically incorporate advanced functionality into a designed product that can be economically mass produced and is capable of delivering a quality, consistent product to the marketplace," Montemagno said.

Montemagno's commercialization strategy is to develop the biomimetic membrane in "the form of a true technology, not just a laboratory demonstration, and then partner with either existing companies or users to commercialize, produce and introduce it to the marketplace," he said. "After nine years of effort, we are very close."

In the U.S., biomimetic membrane research has also been completed at Sandia National Laboratories in New Mexico where researchers have created a synthetic biomimetic membrane made from self-assembled nanopores. By applying atomic layer deposition, the membrane structures were built by adding sequential blocks of chemically active molecules to weave a polymer membrane that is chemically identical to proteins responsible for water purification in human bodies.

But despite the significant momentum, key questions still remain as to the technology's long-term durability and performance in a full-scale setting. Would aquaporin proteins be capable of weathering the repeated fouling and operating pressures in a commercial environment?

"Aquaporins are a complex biological molecule, so there is concern about the long-term robustness of the protein," said Brent Giles, a senior analyst at Boston, Mass.-based Lux Research.

Giles said that, while appealing, engineering the supporting membrane structure and replicating the chemical conditions necessary for facilitating and sustaining molecular aquaporin functionality poses a real challenge. "In their natural state, aquaporin proteins are pores penetrating the membranes of biological cells," he said. "Recreating conditions to maintain the protein's proper structure and functionality in the surface of an artificial membrane that rejects contaminants is a major technical hurdle."

But still, because of the potential to achieve improved water flux, Giles said biomimetic membrane technology is also very attractive in terms of industrial water treatment. "A high flux membrane could achieve better dewatering faster, and ideally, it would do so under a range of conditions," he said. "Forward osmosis, which is a realistic desalination target for aquaporin use, is a particularly gentle way to dewater milk, juices and other industrial fluids. But whether aquaporin-embedded membranes can ultimately be this flexible, or whether competitors' FO membranes will win out instead, remains to be seen."

About the Author: Jeff Gunderson is a correspondent for Industrial WaterWorld. He is a professional writer with over 10 years of experience, specializing in areas connected to water, environment and building, including wastewater, stormwater, infrastructure, natural resources, and sustainable design. He holds a master's degree in environmental science and engineering from the Colorado School of Mines and a bachelor's degree in general science from the University of Oregon.

Archived IWW Issues