Oil & Gas Extraction and Water Quality: Addressing the Challenges of Produced Water

by Ned Godshall, Ph.D., and Matthew Bruff

Produced water is by far the largest volume of waste generated in oil and gas extraction operations. An average of over 9 barrels of produced water is co-produced with each barrel of oil produced in the United States, and, as oil wells age, the proportion of produced water continues to increase beyond that figure, sometimes to as much as 98% of the material brought to the surface.

U.S. oil wells may be more realistically viewed as “dirty water wells,” with the byproduct of oil representing only about 2-to-12% of the actual fluids lifted to the surface. For both oil and gas, the well’s economic life is usually dictated by the amount of water produced – and its cost of disposal – rather than by the true end of the amount of oil or gas underground at the well. So if the cost of produced water disposal could be reduced, the economic reserves of oil and gas in the United States would actually be increased.

Produced water is water trapped in underground formations that comes to the surface during oil and gas exploration and production. It occurs naturally in formations where oil and gas are found and is millions of years old. When oil or gas is extracted, they’re brought to the surface along with this produced water as a combined fluid. The composition of this produced fluid includes a mixture of either liquid or gaseous hydrocarbons, produced water, dissolved or suspended solids, produced solids such as sand or silt, and recently injected fluids and additives that may have been placed in the formation as a result of exploration and production activities.

A Costly Problem

Produced water handling and treatment represents an $18 billion cost to the oil & gas industry in the U.S. alone – the single largest waste stream challenge facing the industry. The cost of produced water handling and disposal includes lifting large volumes of water to the surface, separating it from the petroleum product, treating it, and then injecting it into the ground or disposing of it in surface evaporation ponds.

Historically, produced water generated at an oil or gas site is stored onsite in large tanks. Oil and gas companies must pay for disposal trucking companies to visit the site multiple times per week, pump the produced water out of the storage tanks and transport the waste to commercial underground reinjection sites. These disposal trucks must often travel great distances to the reinjection sites. When these trucks are unavailable or during periods of poor weather, many well sites must be shut down due to the inability to store and/or dispose of the produced water onsite.

In addition, many oil and gas wells are simply “pinching back” production due to inability of onsite infrastructure to handle produced water volumes. Trucking costs alone can be in excess of $3 per barrel (bbl) and a disposal reinjection well can cost upwards of $4 million to drill. In many locations, total produced water disposal costs are greater than $5/bbl. Stated differently, the oil & gas industry spends as much as 80 times as much, per gallon, to get rid of dirty produced water as individuals pay for clean municipal water. Despite considerable efforts and investment, there were no cost-effective technological solutions available to reduce the huge disposal costs of this highly brackish produced water, until now.

A New Approach

Altela Inc. offers a fundamentally new water desalination product, the AltelaRainSM System (ARS), that inexpensively removes nearly 100% of dissolved salts and other contaminants from industrial wastewaters and undrinkable brackish waters – representing the first new, low-cost water desalination technology in the last 50 years.

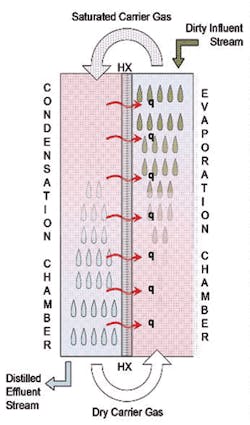

Altela has taken the simplest of nature’s processes for purifying water – i.e., mimicking thermal distillation in the water cycle for making rain – and recreates that process using readily available materials and very little energy compared with conventional thermal distillation or membrane separation. The internal heat transfer technology recaptures the energy needed to evaporate water, thus yielding about three times the amount of distilled water per energy input as traditional ambient pressure distillation/evaporation techniques. Consequently, the technology yields energy costs that are approximately only 30% of comparable ambient pressure distillation/evaporation processes.

These systems lower the cost of oil and gas production while dramatically decreasing the volume of waste that needs to be trucked away and disposed. It purifies the most highly challenged water using energy produced at the wellhead, in a simple, mobile and modular system located on-site. They’re highly scalable in size and can be produced in a variety of configurations to fit individual on-site needs. The standard ARS-4000 system is delivered in a single portable 45-foot x 8-foot shipping container, and treats 4,000 gallons per day (~100 barrels per day, BPD) of produced water, decreasing disposal costs by 90% and extending the life of a well. For higher volume applications, larger systems can be delivered for increased capacity at a given location. They also can be joined together in series to double or triple production capacity.

null