Current Market Outlook and Opportunities Good for Ultra-Pure Water

by Shilpa Tiku

The ultra-pure water (UPW) generation process is a series of unit operations designed to remove contaminants from water to achieve an ultra-pure level. UPW treatment technology has progressed and changed significantly over the years. Major trends include membrane processes in the use of reclaimed and recycled water. Application requirements indicate lower costs and lower detection levels.

Ultra-pure water is of great importance in several industries, including the following:

- Super-critical boilers in the power industry

- Drug manufacturing in the pharmaceutical industry

- Semi-conductor wafer cleaning in the electronics and microelectronics industries

This article addresses some of the market trends, i.e., challenges and drivers for suppliers in this space and strong opportunities in some key markets.

UPW Market Challenges

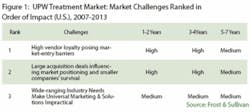

Figure 1 highlights the challenges in the UPW treatment market in North America from 2007-2013.

High vendor loyalty posing market-entry barriers – North American UPW treatment market end users tend to remain loyal to a limited number of suppliers they trust and, as a consequence, commonly don’t try products from other suppliers. The high cost of downtime is one reason for this high vendor loyalty. Most users with high downtime costs fear that an unfamiliar product might cause a production stoppage due to failures or lower performance.

End users, particularly in the pharmaceutical, biotechnology, lab/analytical and microelectronics industries have very high production costs. Problems, for example, with the membranes in their production processes might lead to lower product quality – an eventuality that end users are reluctant to risk. They prefer to remain with familiar vendors whose products they rely on, even though they might not be the best in the market or best priced.

Vendor loyalty creates high entry barriers and is a challenge for small- and mid-sized companies that don’t have resources required to establish a well-recognized market name. This challenge is expected to taper off toward the end of the forecast period, as this market further develops and newer technologies become more refined and accepted.

Large acquisition deals influencing market positioning & smaller companies’ survival – The presence of huge, major global market participants, such as Siemens Water Technologies and GE Water & Process Technologies, accentuates the fact the market will become increasingly dominated by a few large companies, thereby limiting growth of smaller companies. Siemens Water Technologies acquired USFilter as well as smaller alternative technologies, while GE Infrastructure strengthened its Water & Process Technologies division with the purchase of both Osmonics, Ionics and Zenon. The increasing presence and role of the large companies will continue to be a challenge to smaller ones. Smaller companies are likely to go after niche segments, specialize in certain offerings and add turnkey solutions and more intimate customer service to develop long-term partnership with customers.

Wide-ranging industry needs make universal marketing & solutions impractical – Brand identification and marketing are difficult in an industry with such a diverse array of client requirements, each requiring customized solutions; needs vary widely from one industry to the next. Significant investments in time and money are required for problem identification and implementing solutions for each. Targeting customers by sector is a good way to build brands, but not always straightforward or foolproof. Individual companies within the same sector, for example, often operate independently with their own guidelines, restrictions and requirements. Such complexity renders duplicable, or simultaneous, solutions completely unfeasible.

Water treatment companies are facing the challenge of whether to attempt to provide comprehensive solutions to every customer in every market segment. The situation is forcing the water treatment industry to be more selective in companies they target and more strategic in solutions they offer. Large companies as well as small are reassessing where their core competencies lie, and how they can bring the most value to the market and their customers on a country-by-country, region-by-region, industry-by-industry and product-by-product basis.

Factors Driving the Market

Ultra-pure water is a standard requirement in many industrial applications. As such, these industries have no option but to invest in high-quality water production equipment for their plants and facilities.

Technological advances necessitate higher volumes & purity levels from process water – Electronics are the heart of many industry’s products. Technological advances in electronics and electronics production are making their manufacture and construction more and more delicate, miniature and critical. Chief among the potential sources of contamination in microelectronics manufacturing is water.

Manufacture of all electronic products involves use of high-purity water, frequently in large quantities. In the microelectronics industry, manufacturing processes are cumulative, meaning that each process in a facility is affected by the output of the previous process. When particles and other impurities are present in the chemicals, water and gases used in the process, product yield is reduced. Of these, water is arguably the most critical as it comes into contact with the product many times and at every stage of the manufacturing process. Typical manufacturing plants utilize as much as 2,000 gpm of UPW. This need is increasing as technologies dictate higher and higher standards and purity.

Total Market Overview

Figure 2 represents an overview of the total UPW treatment market. The total 2006 U.S. UPW market is estimated at $731 million, with the powergen market accounting for the largest portion of overall revenues. The microelectronics and pharmaceutical UPW industry revenues fall into second and third place, respectively. Increasingly, companies within this industry are working more closely with each other. Larger companies tend to acquire medium-sized companies, and a number of companies are either merging or forming joint ventures, strategic business alliances or partnerships. Eventually, it’s anticipated there will only be a few major competitors, with medium-sized and smaller companies operating under umbrella brands.

Emerging Markets

The U.S. ethanol industry has grown appreciably from the early 1980s when annual production capacity was less than 500 million gallons. The industry continued to develop and growth remained steady through the ‘80s and ‘90s. Since 2000, the ethanol industry has been exhibiting annual growth between 17% to 20% – unheard of in many industries. Such phenomenal growth can be attributed to escalating world oil prices as well as various state and federal incentives promoting ethanol usage. This trend is expected to continue for several years before tapering off.

Issues related to the importation from, and reliance on, geopolitically unstable or hostile petroleum sources has fueled interest in alternative energy sources like ethanol. Most U.S. ethanol production is concentrated in the corn-producing Midwest. Increasing nationwide demand has, however, resulted in establishment of several new projects outside these traditional states. In 2005 alone, the construction and expansion of dozens of refineries began in California, Ohio, New Mexico, Texas and Colorado.

Competitive Strategies

Companies are making acquisitions, forging alliances, and establishing partnerships to broaden their product offerings and capitalize upon existing relationships within niche industry sectors. Alliances with existing entities are increasingly seen as alternatives to market entry in select end-user markets.

Product quality and performance are expected as well as a given in this highly competitive market. Still, suppliers irrespective of their dominance in the market place, should continue to strive for a more customer-specific service support, be sensitive to the low capital investment capabilities of several end users.

End users, especially small companies, are very receptive to new entrants in the marketplace. Monitoring multiple offices and maintaining a uniformity and excellence in product and service offering can become challenging in the long run. Continued success can only be maintained with a close working relationship with the end users.

About the Author: Shilpa Tiku is an industry manager for Environmental & Building Technologies at global growth consulting company Frost & Sullivan. Contact: www.environment.frost.com