Saving Energy through Boiler Water Treatment

• Canada’s largest carpet maker, Beaulieu, turns to purified tannin-based chemical additives from Servivap to improve boiler efficiency, reduce corrosion.

by Patrick Crow

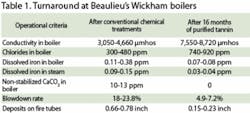

Servivap Canada Inc.’s tannin additive for boiler water has eliminated scaling problems for carpet conglomerate Beaulieu Canada and cut its energy costs C$200,000 (US$193,493) per year. The carpet manufacturer said, since it introduced one of Servivap’s MK 3100 purified tannin products at its Québec plants, blowdown has plunged 80% because boilers can operate at much higher conductivity levels.

Beaulieu is the first North American company to use the purified tannin additive, which could be used extensively in Canada and the United States to reduce boiler corrosion and stop formation of deposits, according to Servivap.

Hard water problem

Beaulieu is Canada’s largest manufacturer and distributor of tufted broadloom carpet, holding 53% of the market. It operates more than 200,000 lbs/hour of boiler capacity at a spinning plant at Wickham and manufacturing plants at Acton Vale and Farnham. It uses the steam to heat water and buildings, fix dyes and humidify ambient air for yarn spinning.

Heavy scaling had been a problem at the two Wickham boilers. The local water district couldn’t provide the large volumes the plant needed, so the company has been pumping relatively hard groundwater from its own well.

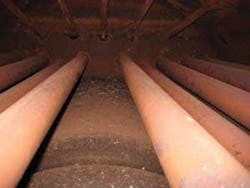

Beaulieu said conventional water treatments with sulfites, phosphates, phosphonates and amines failed to alleviate its scale and corrosion problems. One reason was that fluctuations in water usage and total hardness concentration resulted in 1-3 ppm of CaCO3 going through the softener. It was too difficult to reconfigure mechanical water softeners every 24 to 72 hours. Beaulieu said corrosion and deposits of calcium phosphate, calcium silicate and calcium carbonate were as much as an inch thick in the boilers.

Servivap’s solution

Servivap Canada, established in Montréal in late 2005, is affiliated with Servivap France and is developing the North American market for Servivap France’s purified tannin water additive. More than 200 Servivap France customers have used purified tannin in 500 boilers for the past two decades in Europe and elsewhere.

“Except for purified tannin, there has been no major change in boiler water treatment for the last 50-60 years,” said Gary Schwartz, CEO of Servivap Canada. “Most companies offer the same lines of chemicals – sulfites, polymers, phosphates, phosphonates and amines – under different names. While these can be effective for specific applications, they all have their limitations.”

Non-purified tannin has been available since the 1970s but has its limitations, too. Tannin’s natural impurities, unless removed by Servivap’s treatment, restrict its effectiveness.

Dr. Michael Soll, Servivap France’s research and development director, discovered a process to purify the tannin, enhancing its properties as an oxygen scavenger and a medium for fixing the non-stabilized hardness in water.

Purified tannin has a number of advantages. The natural compound is non-toxic, non-flammable, and biodegradable. In the boiler, it forms a dynamic, homogenous iron tannate film of less than 0.1mm, protecting the metal surface from corrosion.

It immediately stabilizes salts and allows boilers to operate in a range of 8,000 to 10,000 micromhos of conductivity, cutting blowdown volume without carryover of contaminants into the steam. Other additives don’t stabilize salts as effectively and boilers using them must operate at conductivity levels of 2,000-4,000 micromhos to prevent foaming, which adds to carryover.

With purified tannin, the increased salts in concentration are removed with the blowdown. The tannin optimizes steam quality with a conductivity of 5 to 15 micromhos and a pH of 7.5 to 8.5 to protect the condensate returns.

“All of our clients, including Beaulieu Canada, are running at these higher conductivity levels and have realized significant energy savings without problems,” Dr. Soll said.

Beaulieu’s testing

Beaulieu calculated that it was more economical to use Servivap Canada’s MK 3106 purified tannin product (which included ammonia) at Wickham than to build a plant to upgrade the water quality.

Servivap also made an offer that Beaulieu couldn’t refuse: It guaranteed to pay for descaling and to buy back any unused MK 3106 if the additive failed to reduce boiler deposits.

“Initially we were skeptical of the product, but since we were curious about the potential results, we decided to test it at Wickham,” said Sylvain Roy, Beaulieu’s engineering director.

The company was working to achieve ISO 14000 environmental management standards and wanted to improve its boiler blowdown effluent. The Servivap formulation was a one-stop solution that also offered potential for fewer blowdowns and a parallel decrease in energy costs.

“Prior to this, we had been opening our boilers at Wickham every three months to monitor the levels of deposits. We began the trial in January 2006 and it was clear to us even at the first opening that we were seeing results. The deposits were being reduced and we noticed a drop in our natural gas consumption.

“Due to the poor water quality, our blowdown rate had been 25%. By using the MK 3106 product we were able to lower this rate to 5%, resulting in a 20% saving of feed water and a blowdown reduction of 80%,” Roy said.

“At each subsequent boiler opening, we have seen a further shrinkage in the thickness of deposits at the Wickham plant. The installation of the product was very straightforward and it cut our operators’ time through simplified testing and monitoring procedures.”

In July 2006, Beaulieu began using Servivap’s purified tannin to control scale in boilers at its other two Quebec complexes, even though they used a better quality municipally-supplied water.

Roy said, “At each of our plants, we have noticed significant reductions in energy consumption and expenditures, as well as water consumption. The insides of our boilers are all at the metal surface and the Wickham plant is close to returning to the original metal.”

He said boiler operators tend to be conservative, sticking with products they know. “The most difficult thing about the test was trying to persuade everyone beforehand that this product really might work. Well, they’re persuaded now.”

Acknowledgment: The author would like to thank Montreal’s Servivap Canada Inc. for its assistance on this article. Contact: 877-525-8118, [email protected] or www.servivap.ca

About the Author: Patrick Crow is a freelance author living in Houston, TX.