Boiler Feed Water Treatment for Industrial Boilers and Power Plants

By Michele Monroe

In the steam boiler industry, high purity feed water is required to ensure proper operation of steam generation systems. High purity feed water reduces the use of boiler chemicals due to less frequent blowdown requirements (reducing blowdown frequency by as much as a factor of 10). Lower blowdown frequency also results in lower fuel costs. Scale buildup is reduced due to a smaller concentration of impurities in the boiler feed water to foul heat transfer surfaces. The lower level of impurities also reduces corrosion rates in the boiler. When a boiler is used to run a steam turbine, turbine blade erosion is reduced due to higher purity steam generated.

Use of reverse osmosis (RO) in feed water purification systems reduces chemical costs by reducing the frequency of ion exchange regeneration. A complete system, which includes RO and ion exchange, typically results in a more cost effective system when compared to systems that don't use RO. The use of conventional RO, however, requires substantial use of pretreatment unit operations that also adds to the system's total cost.

Silicate and colloidal deposits decrease boiler efficiency and also result in premature failure of turbines. Ultrafiltration can remove greater than 99% of colloidal silica, as well as precipitated iron and aluminum. The reduction in particulate matter, suspended solids and total organic carbon (TOC) also enhance turbine and boiler efficiency. But use of conventional membrane technologies has faced substantial membrane fouling problems.

Objective

To promote optimum performance downstream, filtration of boiler feed water streams allows an industrial boiler or power plant to meet the stringent requirements for more efficient boiler performance. Treatment of boiler feed water is required for preventing excessive heat transfer equipment fouling and erosion of turbine blades.

Solution

Technological advances in membrane filtration systems create an opportunity for industrial boilers and steam power plants to treat boiler feed water streams to meet stricter system performance. Vibratory shear enhanced processing or VSEP®, developed by New Logic Research, makes it possible to filter influent water or effluent wastewater streams without fouling problems exhibited by conventional membrane systems. The membrane system significantly reduces TDS, TSS, TOC, color bodies, silica and hardness from influent streams originating from city water, well water, and river/surface waters – thus minimizing treatment cost.

The treatment system uses ultrafiltration (UF), nanofiltration (NF) or RO membrane modules to treat influent water to generate a permeate stream that meets boiler feed water criteria regarding concentrations of suspended and dissolved solids, silica, and hardness. After final polishing by ion exchange resins, the clear permeate can then be used as boiler feed water. RO filtration can be used if near complete dissolved solids removal is required, and some have begun using spiral wound membranes for this task, i.e., a final polishing step.

In summary, the treatment system can be used to treat boiler feed water with only minor final polishing by ion exchange resins. This alternative separation process eliminates pretreatment requirements and can substantially reduce chemical usage for regeneration thus reducing disposal of spent regenerant and associated costs.

Several technologies are currently being used for boiler feed water treatment. Table 1 compares this process to select competitive technologies such as chemical addition/clarifier systems and crossflow filtration/spiral membranes. As illustrated, vibratory shearing technology offers significant advantages over these other methods.

For the industrial boilers and power plant systems, as well as the cogeneration industry, membrane systems employing the process can now be utilized where traditional crossflow membrane technologies faced substantial membrane fouling problems in the past. It's an attractive alternative to conventional filtration methods due to its vibrational, shear-enhanced design.

Process Conditions

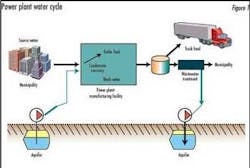

Figure 1 presents a schematic of a power plant water cycle. Influent water to a power plant may come from a groundwater well (aquifer), surface waters or a municipality. The water has to be treated to meet boiler feed water criteria. Within the boundaries of a power plant, treatment of boiler condensate and its recovery, and treatment of wastewater generated from flue gas treatment scrubbers, are additional important water treatment challenges. For boiler feed water treatment, depending on its requirements, a number of processes can be utilized, including chemical treatment/ lime softening, dual media filtration, carbon adsorption, conventional RO membranes, and final ion exchange resin polishing. Significant waste is generated from these operations, including spent carbon and regenerant chemicals from ion exchange resins.

The vibratory shearing process has two major applications in the power plant. The first is processing of boiler water influent. To avoid boiler scale, power plants usually utilize a multi-step process to remove hardness of incoming water, including either chemical treatment or ion exchange and several less advanced methods such as multimedia filtration. These multi-step processes can be replaced by a single-pass VSEP machine that purifies the influent in one step.

Another issue for power plants is disposal of waste streams such as scrubber effluent. Of course, several methods exist to perform all of the above functions but, again, a multi-step process is often employed. A typical wastewater treatment process might include chemical addition, then a clarifier, a filter press, and finally ion exchange. This newer technology is unique in that it aggregates the entire operation into one machine. All of the systems mentioned could be replaced using a single vibratory shearing unit equipped with nonporous membranes to remove everything from large ash particles to individual gypsum molecules. The resultant water quality is as high as that produced by multi-stage filtration and chemical addition.

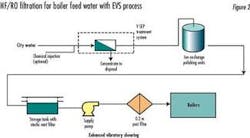

A process schematic for treatment of boiler feed water using this treatment system is presented in Figure 2. The system uses an NF or RO membrane filtration system to replace the entire pretreatment step usually required, i.e., lime or cation softening, dual media filters, carbon adsorbers, and conventional RO units. City water is treated in a single-step VSEP treatment system followed by a final ion exchange polishing unit. The treated boiler feed water is then fed to the boiler via a supply pump.

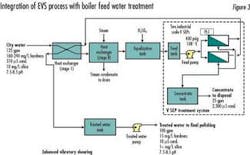

Figure 3 is a process block flow diagram showing integration of a vibratory shearing system with boiler feed water treatment at an industrial manufacturing facility. This diagram also includes the overall material balance for the water treatment process and illustrates its performance.

As presented in Figure 3, city water is preheated in the Stage I heat exchanger with clean permeate water from VSEP and is then further heated with a steam-heated exchanger to a temperature of 42°C (108°F). The higher feed temperature improves permeate flux through the treatment unit and provides the energy drive for the first exchanger. The preheated water is introduced into the equalization tank where sulfuric acid may be added for pH adjustment. Other chemicals such as alum and polymer can also be injected at this point as needed to help coagulation. The equalization tank effluent is then transferred to the feed storage tank where it is fed to the units at a rate of 125 gpm. Two industrial scale units process the preheated city water.

This alternative membrane system generates a permeate stream of about 100 gpm that's sent to the heat recovery exchanger and then stored in the treated water tank prior to final polishing by ion exchange. It produces a concentrated waste stream at a flow rate of 25 gpm, which is routed to the holding ponds and then the sewer.

Two industrial treatment units, with NF or RO membrane modules, are provided. The raw city water has a concentration of 160 to 240 mg/L of hardness, ~10 mg/L of silica, and ~510 µS of conductivity. The permeate concentration is reduced to <15 mg/L of hardness, <1 mg/L of silica, and ~10 µS of conductivity – all well below the designed water quality limits.

Using a NF or RO module in this system is a commercially viable option for treatment of boiler feed water at industrial boilers and power plants. Nearly 80% of the influent water is recovered as treated water suitable for final polishing at a boiler facility, while less than 20% is disposed as concentrate. Membrane selection is based on material compatibility, flux rates (capacity) and concentration requirements (hardness, silica, TDS, conductivity). In this example, hardness reduction is over 90% and TDS and conductivity are reduced by a similar rate. The permeate quality from the system can be controlled though laboratory selection of membrane materials available to fit the application parameters.

Depending on influent water concentration levels, process temperatures, membrane selection and requirements for reduction of hardness, silica, and conductivity from influent streams, the permeate flux rate in the VSEP system can range from 20 to >70 gallons per day per square foot of membrane (gfd). The concentration level exiting the unit is controlled by an automatic timed control valve. This valve is set such that the solids concentration is held at the desired level. A multi-stage feed pump supplies the unit at a pressure suitable for the membrane used. A variable frequency electronic drive is used to set feed pressure through a PID (proportional-integral-derivative) control loop. The variable speed drive acts to control rotational speed of the pump, thus controlling the flow rate.

Conclusion

New Logic's VSEP system provides an alternative approach for boiler feed water treatment applications. In a single-step operation, VSEP will reduce hardness, TSS, TDS, and conductivity to provide a high quality boiler feed water stream for industrial boilers and power plants. In many applications, the addition of VSEP will eliminate conventional treatment process requirements and technologies without chemical treatment demands and the by-products they generate. The justification for use of this treatment system in your process is determined through analysis of system cost and benefits including:

• Reduction of hardness, TSS, TDS, and conductivity for the plant influent stream.

• Provision of high quality water for introduction into the boilers or process.

• Reduce or offset fresh water demands and pretreatment cost.

• Retain heat in recycled process water as a possible method to reduce energy requirements.

• Elimination of biological growth, and odor in effluent.

• Reduction of effluent discharge volume and associated treatment cost.

• Simplify influent or effluent treatment with a compact, low energy system.

This separation technology has been successfully installed into many industrial processes. The industrial boilers and power plants as well as the cogeneration industries' effort to meet system performance criteria and environmental regulations are enhanced with utilization of membrane filtration combined with the enhanced vibratory shearing process. Development towards applications for industrial boilers and power plants, along with availability of new membrane materials and VSEP technology make it possible to treat more difficult streams with technically and economically successful results.

About the Author: Michele Monroe is a senior engineer and also international sales manager for New Logic Research Inc., of Emeryville, CA. She can be reached at 515-655-7305 or [email protected].