Chlorination for Food Processing Operations

Chlorination of domestic, public and private water supplies has been used since the early 1900s to safeguard against waterborne diseases. In recent years, chlorination of industrial water has become a common practice in food processing plants as a means of improving plant sanitation. Chlorination can include use of chlorine gas, hypochlorites or chloramines.

When used in a food processing plant, chlorine must be applied under controlled conditions if the desired germicidal effects are to be obtained without adverse results. Moreover, chemical and physical characteristics of the water - such as average pH, temperature, chlorine demand, concentration of organic matter, volume and the presence of phenols or other materials which might affect flavors - must be known in order to ensure the effective and efficient use of chlorine disinfection.

Regardless of the type of chlorine compound used for disinfection, free chlorine residuals of 4-7 parts per million (ppm) at the point of water application to equipment are recommended. If the operations are light (e.g., only one shift), satisfactory control may be maintained with lower concentrations, whereas during heavy operation 5 ppm may be required. An increase to chlorine residuals of 10-20 ppm is recommended for cleanup purposes. This serves to give an effective germicidal treatment to all equipment in the plant.

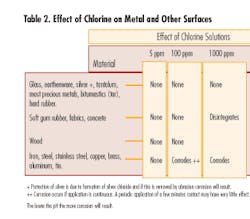

The chlorination of water in food processing plants could potentially affect food quality and the can or plant equipment. Research performed by the National Canners Association on the effects of chlorine on the flavor of 29 fruits and vegetables shows that a few items - apples, pears, cling peaches, figs, strawberries and yams - are the most susceptible to chlorine flavor. Testing further shows that a chlorine concentration of 5 ppm has no effect on the color or ascorbic acid content.

While corrosion attributable to chlorination isn’t normally a problem in food processing applications, its possibility shouldn’t be ignored as chlorine can be corrosive to common metals such as brass, aluminum and steel. Still, research and field experience has shown that in low concentrations (2-5 ppm) it doesn’t noticeably corrode either the cans or equipment. In fact, even at high concentrations (10-20 ppm) typically used for cleanup, chlorine doesn’t produce significant corrosion because the contact time is too short. Moreover, corrosion is most severe in conditions where slime deposits exist - and the use of chlorine helps prevent slime formation.

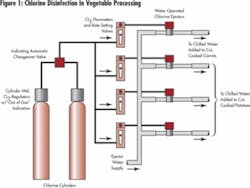

For in-plant chlorination to be most effective there should be a continuous application of chlorinated water to all surfaces where bacteria are likely to grow and slime to form. This may involve additional piping. For belts, bucket elevators, reel washers and similar equipment, the chlorine may be applied by installing sprays of chlorinated water in such a way that they’ll constantly bathe the moving surfaces. Best results are obtained on belts when chlorinated water is sprayed on both sides of the belt.

For equipment such as fillers, dicers and peelers where a continuous application of chlorinated water isn’t possible, water lines with short hoses should be installed near each machine to be used for washing the equipment each time operations cease. As a precaution against off flavors, it’s advisable to install lines of unchlorinated water for syrup or brine making, for boiler water and for drinking purposes.

Regardless of the source of chlorine, only automatic equipment that feeds chlorine in proportion to the water flow should be used. This is necessary to avoid fluctuations in the chlorine level that if too low would be ineffective or, if too high, might produce off flavors and corrosion.

After the installation of the chlorine disinfection system, it should be turned on for at least a week before canning operations are commenced to “burn out” all organic matter in the lines. This will help eliminate chances of off flavor and will reduce the potential of employee objections to unpleasant odors. It’s recommended an experimental pack using the chlorinated water be made prior to the start of operations to determine the possibility of off flavor. All cresols, phenols or phenol-like compounds should be removed from the plant because chlorine in combination with such materials produces compounds with a very strong flavor even when present in minute quantities. Material that may contain phenols and cresols include marking inks, paints, fly sprays, special wood sealers, hand lotions and boiler feed water compounds.

Continuous laboratory control is essential for safe application of in-plant chlorination, and the following schedule is recommended:

• Check the chlorine residual every two hours to help establish the variations likely to be encountered.

• After the first week, check the chlorine residual at several points in the plant at least twice a day, sampling the same places each day. Sample should be taken from a tap that has been running for several minutes.

• Record all residuals observed and taste the water (if potable) every time a residual is taken as a check on possible off flavors.

• Record the chlorinator setting each time the residual is taken.

• Weigh the chlorine cylinder each day at the same time, and record the loss in weight to ensure the accuracy of the chlorinator feed setting and to determine when a new cylinder is needed.

• Check the chlorinator operations, and at least once a day inspect for leaks using an ammonia bottle.

Conclusion

Improved sanitation can be achieved through the efficient and effective use of in-plant food processing chlorine disinfection systems. IWW

The above article appeared in a newsletter of Severn Trent Services, based in Fort Washington, Pa. It’s reprinted here with permission. To read the full technical bulletin, “Chlorination in Food Processing Plants,” visit: www.severntrentservices.com/documentation/!gas_feed_documentation/!Documentation/Documentation_Breakdown/4000-Applications/010-4695.pdf. Registration is required for access, but is free. For more information, contact [email protected].