Zero-Sludge Treatment of Industrial Wastewater By Ken Norcross

Industrial wastewater treatment is an unusual engineering challenge. Where else in industry are the designers asked to provide a process that will produce a very high level of efficiency and reliability while being given an unpredictable, inconsistent and highly variable raw material with which to work? This conundrum is further compounded if, as is often the case, the waste is highly concentrated, high in salts or hot.

High concentrations of organics (>5,000 mg/LBOD) pose two challenges. The mere concentration issue means even very efficient treatment can leave a significant effluent concentration (98% efficient treatment of a stream with 10,000 mg/L BOD still leaves 200 mg/L in the effluent.) Further, a stream with a high concentration of BOD will release a lot of heat from bio-oxidation of organics, which can cause mixed liquor temperature to exceed the mesophilic range; this typically results in deflocculation, foaming and high effluent TSS.

High salt concentration (>1,000 mg/L) contributes to high effluent TSS as dispersed solids increase with ionic strength of the solution.

Hot wastewater typically must be cooled prior to treatment to insure the mixed liquor stays in the normal mesophilic temperature range (18-35°C), where most plants operate, and foaming and effluent clarity are easier to control. Biological activity is much faster and more efficient at higher temperatures, however, and thus much smaller reactors are required.

When the desired level of clean effluent finally is achieved, the owner is faced with the vexing question: “How do I pay for the river of noxious waste sludge we’re generating every day?”

And at typical sludge generation rates (0.5-0.9 gTSS/gBOD), there are literally millions of pounds of sludge generated daily in the United States alone. Its fate will be the question of the decade for industrial wastewater treatment plant owners and operators. Europe has already passed severe restrictions on disposal of sludge in landfills, with total bans in sight. California has followed suit with rigorous new legislation proposed. This trend will spread as nobody wants industrial sludge hauled into his or her backyard. Many state regulatory “sludge gurus” have said the cost of sludge treatment is going to spiral upwards quickly and permanently.

But there are alternatives to the effort and expense of endlessly hauling sludge from your plant.

No-Sludge Solution

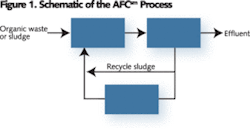

The AFCsm , available from PMC BioTec, is a catalytically enhanced membrane bioreactor (MBR). Raw influent is fed to a self-heating thermophilic bioreactor for treatment (see Figure 1). Mixed liquor is recirculated through an ultrafiltration (UF) membrane system for solids separation (which eliminates flocculation and settling problems caused by high salt and/or temperature). A small portion of this flow goes through a small chemical treatment reactor. The chemical treatment step partially solubilizes the excess biosolids before they’re returned to the bioreactor for ultimate digestion and destruction. Field experience has shown the chemical treatment step also acts to suppress foaming in thermophilic reactors and enhances membrane flux rates.

Characteristics of catalytically enhanced MBR systems include:

• Little or no waste sludge production - Most full-scale systems produce zero waste biosolids.

• Handles hot wastes - Readily operates from 10-70°C.

• Very small footprint - Requires only 20% of the footprint compared to conventional activated sludge systems. High temperature operation speeds up kinetics 100-300% over conventional systems; membrane system keeps solids in - with MLSS levels up to 30,000 mg/L typical (remember, it’s hot - so viscosity is low!).

• Simple Operation - Operation is simplified since the catalyzed MBR largely frees the operator from worry over mixed liquor flocculation and settling and clarifier solids management, etc. The UF membrane insures effluent with less than 5 mg/L TSS. Finally, there’s little or no excess sludge to waste-digest-stabilize-thicken-dewater-store-transport-dispose of (and thus no associated equipment to build and operate).

Bottom Line Results

An example of this in-the-field performance is a specialty chemical manufacturer faced with $2.7 million per year for off-site disposal ($0.5/gal) of 15,000 gpd of high-strength wastewater with high brine (8% salt), high COD (130,000 mg/L), high BOD (40,000 mg/L), and 400 mg/L of toluene. Corporate staff decided to evaluate the AFC no-sludge process to reduce offsite disposal costs. Bench testing, field pilot and engineering analyses indicated that significant cost savings would be achieved with the process. The full-scale system (see Figures 2&3) started up in the spring of 2000.

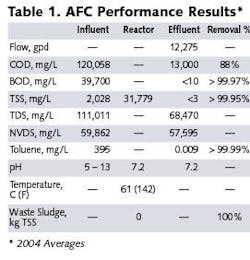

Influent loading rates and concentrations were, predictably, widely variable. Due to high rates of biological heat release, the system operated as predicted in the thermophilic range at 142°F (61°C). Foaming was suppressed by the integral ChemTreat system, wherein a small stream of return mixed liquor is subjected to aggressive ORP (oxidative/reductive) conditions to affect cell lysis and enhance biodegradability of recalcitrant organic molecules. No defoamer is currently used in the system. Over years of operation, effluent quality has consistently improved and reliably met performance criteria (see Table 1).

The lone plant operator has this to say after five years operating the system: “The average influent wastewater characteristics have been CODs of 120,000 mg/L; toluene = 400 mg/L; TDS levels approaching 80,000 mg/L. COD removals have averaged 90% with effluent BOD levels near non-detect, and toluene levels less than 0.010 mg/L. Since start-up, the AFC system has treated over 15 million pounds of COD with zero waste sludge production,” said plant operator Ray Hardison of the specialty chemical company where the system was installed.

He continued, “The PMC BioTec team worked closely with me during startup of the system and continues to provide operational support when needed. I have been the lone operator responsible for the system since startup and continue to monitor the system, including daily analytical testing. The cooperation and support I received has contributed to a successful project resulting in savings to our company of about $1 million annually compared to off-site disposal.”

Conclusion

This project, among others, shows that it’s possible and economically feasible to design and operate biological treatment systems that achieve the “Holy Grail” of zero-sludge production while being easy to operate, and producing effluent quality with less than 10 mg/L of BOD or TSS. IWW

About the Author: Ken Norcross is executive vice president of PMC BioTec Co., which is based in West Chester, Pa. Norcross has over 27 years of experience in the treatment of industrial wastewater and residuals. He has published and presented numerous technical papers and has authored 15 related patents. Contact: 913-706-9656, [email protected] or www.pmcbiotec.com.