Development of an Efficient Bacterial Culture to Degrade 1,4-Dioxane

Two Massachusetts companies have developed the first in-situ bioremediation technique for the destruction of 1,4-dioxane (C4H8O2, CAS No. 123-91-1), a widely distributed groundwater contaminant commonly used as a solvent stabilizer, especially with 1,1,1 trichloroethane (TCA).

Using proprietary bioenrichment techniques, Innovative Engineering Solutions Inc. (IESI) and Bioremediation Consulting Inc. (BCI) cultured a propanotrophic organism (one that utilizes propane as a sole carbon source) to aerobically degrade at least 10 mg/L of 1,4-dioxane within hours of application. Although propane-enhanced microbial oxidation of chemicals, including 1,4 dioxane, is a known remedy, the team is the first to develop techniques for enrichment of native propanotrophs that can degrade dioxane, resulting in an application-ready culture available for bioaugmentation, as well as a safe and reliable dissolved-propane subsurface delivery method.

In the lab, scientists developed the SL-D culture, starting with a sample of groundwater from a contaminated site in Salt Lake City, Utah, which contained the bacteria already adapted to the conditions of that site. The technology, now being tested in the laboratory, has been shown to degrade 100% of the 1,4 dioxane within 12 hours. The microorganism was not genetically engineered in the laboratory, since it had already developed the ability to degrade dioxane when provided with propane. For full scale application at a large site where bioaugmentation is required (native propanotrophs are not present), the cultures are maintained in a 200-gal on-site reactor for periodic dosing to the subsurface at different locations within the contaminated zone.

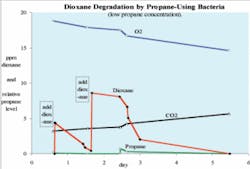

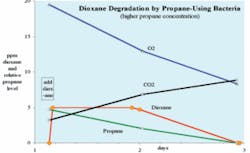

Bioenhancement is achieved by maintaining dissolved O2 and propane in the reactor and in the subsurface. Propane is solubilized in water in a tank maintained at pressure slightly above 1 atm and dosed to the tank. Oxygen is obtained from a dilute (less than 0.5 %) solution of hydrogen peroxide. Injection/sparging of propane gas into the subsurface would result in volatilization of most of the injected propane into the vadose zone, resulting in potentially dangerous subsurface conditions. By injecting pre-solubilized propane this issue can be avoided. Injection of dilute peroxide allows delivery of supersaturated, oxygenated water to the subsurface. A pulse-feeding mode was devised for the propane so as to maximize dioxane degrading activity of the SL-D microorganism.

“We’ve found that the microbe feeds on propane, leaving the dioxane untouched until the concentration of the propane is reduced. At that point, the organism begins a dioxane feeding frenzy,” said Sami Fam, president of IESI. “We’re trying to determine if the destruction of dioxane is co-metabolic or if the propane is a starter and dioxane is an energy source.”

BCI is currently conducting additional testing to evaluate how ubiquitous the organism is and the extent of the propane requirement.

The key economic benefit of in-situ bioremediation of 1,4 dioxane is the reduction of the project duration. Capital and annual operation and maintenance costs for in-situ and ex-situ remedies, with similar destruction capacity (90% or greater), are not very different for treating a given site. In-situ chemical oxidation is generally limited to small areas due to cost and oxidant lifetime.

Aboveground groundwater treatment using ultraviolet light or ozone oxidation techniques, while successful, rely on flushing an organic compound from the subsurface by the groundwater, requiring very long desorption times, making ex-situ treatment typically 2-20 times more costly than in-situ treatment. With SL-D, distribution of the treatment solution is key. If the SL-D organism can be maintained in the ground, approximately 10 ppm, dioxane can be degraded within 3-6 months. An ex-situ cleanup that would take 30-50 years could be done in 3-5 years using in-situ bioremediation techniques. The IESI/BCI team plans to achieve 95-99% in-situ destruction of up to 50 ppm of 1,4 dioxane, says Fam.

For more information, Innovative Engineering Solutions Inc., a Norwood, MA, provider of environmental consulting services specializing in bioremediation systems for CVOCs and founded in 1995, can be contacted at 781-255-0796 or www.iesionline.com. Established in 1991 in Watertown, MA, Bioremediation Consulting Inc., a laboratory offering microbiological culturing, testing and analytical services, can be contacted at 617-923-0976 or www.bcilabs.com.