Outsourcing Water & Wastewater Treatment in the Microelectronics Industry

By Usha Srinivasan

Although the context of this article is the outsourcing of industrial wastewater treatment and production of process water, the concept of "outsourcing" in the manufacturing industry in general has been given a great deal of attention in recent years by the media and the public. Anyone who is an avid watcher of Lou Dobbs on CNN can attest that he never closes his segment without mentioning the impact of outsourcing on the American job market. Many multinational companies, however, continue to outsource their manufacturing along with, consequently, the transfer of water and wastewater management, and environmental, health and safety issues overseas.

The Semiconductor Industry

An important segment of the microelectronics sector is the semiconductor industry, a high growth technology segment with tremendous application prospects.

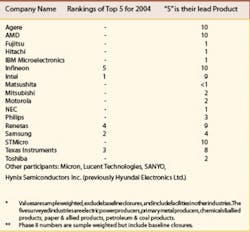

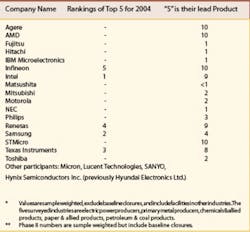

Figure 1, shows the top 20 semiconductor companies in this sector. Of the listed companies the expected rankings of semiconductor companies at the end of 2004 is also indicated in Figure 1. The top player in this market, Intel is expected to close at 30 Billion in 2004. The next four big companies include Samsung, Renesas, Infineon and (TI).

In addition, a number value of 1 to 10 (with 10 being the highest) included in the third column next to the revenues of each company indicates the degree to which semiconductors are their lead product offering. This has merely been included as a means to assess potential companies that may be seeking O&M partnerships in the United States and globally. For example, the companies with top values assigned, namely Intel, STMicro, TI, Infineon, AMD, Renesas, and Agere, are solely dedicated to semiconductor manufacturing.

The Semiconductor Industry Association (SIA) is the leading voice for the semiconductor industry and has represented U.S semiconductor companies since 1977. SIA member companies comprise more than 85% of the U.S. semiconductor industry.

The SIA released its annual forecast for 2004-2007 on Nov. 3, predicting record sales of $214 billion in 2004 followed by essentially flat sales in 2005. The forecast projects that sales will grow by 6.3% in 2006 and by 14.2% to $259 billion in 2007. According to the SIA, projections of a less favorable supply-and-demand balance for memory products will be the major factor in dampening industry expansion next year. For the longer term, the new forecast projects a compound annual growth rate of 11.8% through the forecast period.

Click here to view Table 2.

This forecast and promising growth for the U.S. and global markets indicates likely construction of new plants and increase in production within existing plants, which will inevitably be matched with increasing environmental and waste management concerns.

EH&S Initiatives

According to the SIA, the U.S. semiconductor industry ranks in the top 5% of durable goods manufacturers for safety, with only 1.9 reportable injuries and illnesses per 100 employees. This outstanding safety record, the association says, is due in part to its long and close involvement in matters related to environment, health and safety (EH&S). This includes:

• Studying potential health risks to cleanroom workers.

• Working to reduce emissions of global warming gases.

• Weighing in on the most appropriate environmental regulations.

Still, there are certain regulations from which the SIA has struggled to eliminate its industry as a blip on the EPA radar. While SIA members have come to some resolutions to meet expectations of both parties at the present time, growing concern for the environment and watershed protection indicates that even if certain chemicals are not eliminated from use, they'll most certainly be under scrutiny for higher toxicity limits or effluent discharge limits. This is true for both air and water related pollutants and two specific examples are listed below:

1. Perfluorooctyl and Perfluoroalkyl Sulfonates: In a joint effort, the SIA and photoresist suppliers succeeded in retaining use of perfluorooctyl sulfonates (PFOS) and perfluoroalkyl sulfonates (PFAS) in leading-edge photoresists and anti-reflective coatings. These materials are essential to the future of semiconductor manufacturing in this country, at least through 157 nanometer (nm) lithography.

Based on perceived toxicity and environmental concerns, the EPA had intended to phase out PFOS and PFAS through the Significant New Use Rule (SNUR) process under the Toxic Substances Control Act. The coalition, however, argued that these chemicals are used in small quantities and are soundly managed, posing no risk to worker health or the environment.

As a result of the cooperative effort between SIA, SEMI, and the EPA, a PFAS SNUR was finally published in the Federal Register in 2002. It provided an exemption for uses in photolithography. A mass balance model developed for use in evaluating the potential environmental impact has been adopted by the EPA for use with other chemicals. The EPA is also championing the use of this approach in international forums with regulatory agencies worldwide.

2. Maximum Achievable Control Technology: SIA subcommittees have assisted the EPA in defining the Maximum Achievable Control Technology (MACT) standard for the industry – a technology based air emission standard authorized by the Clean Air Act. While the effort to have the EPA exempt the semiconductor industry from MACT requirements was unsuccessful, the SIA does not expect the proposed standard to pose an undue burden on the industry participants.

With such changes this industry is likely to benefit from operations and maintenance (O&M) partnerships, that can minimize risks, ensure safe and compliant operations, improve cash flow and maximize the life and efficiency of their operating facilities

Industrial O&M Market

Market participants anticipate growth opportunities in the O&M market; but before analysis of the trends in industrial outsourcing, it's important to know the market players and top companies operating in this sector. The total municipal and industrial O&M market reached close to $1.5 billion in 2003, of which the industrial market is estimated to be between $400-420 million. There are common market participants in the municipal and industrial outsourcing space, with a few exceptions. Figure 2 lists companies that operate in the industrial outsourcing market, their affiliates and parent companies.

Specific to the industrial outsourcing market, Veolia Water North America maintains more than 80% of the market share and is a leader in the microelectronics industry in not only providing wastewater treatment and water reuse technologies but also assisting in industrial process water, or ultrapure water, production. Among its customers are companies listed earlier in Figure 1, such as Samsung and Hynix semiconductors, which are among some of their largest customers.

The majority of private corporations manage their own wastewater treatment functions. There is a definite sector-based difference in the preference to outsourcing. Even corporations are finding it difficult to conduct their waste management with continual new and stricter regulatory compliance requirements coming from the EPA, especially for contaminants associated with industrial activities.

Growth in this market is difficult to assess, although many market participants predict it is in the 10% per year range. Some large companies such as IBM, Intel and Coca-Cola have completely outsourced their waste treatment, while many smaller establishments are also becoming increasingly interested in such partnerships. The outsourcing trends are highly industry specific, with the food-and-beverage and power generation industries amongst the pioneers in this area. More of the larger corporations prefer complete transfer of waste management services to the more experienced engineering companies, while many of the smaller companies are seeking long-term relationships as well. Complete outsourcing of the operations not only alleviates involvement in the regulatory front but also eliminates management of the staff, payrolls and benefits of those involved in the "outsourced" services side of the operations.

Outsourcing Trends

Among the microelectronics companies listed in Figure 1, not all outsource their industrial wastewater treatment, but Samsung, Texas Instruments, IBM and Hynix are definitely companies that currently have partnerships with solely O&M companies such as Veolia Water North America or environmental engineering companies such as Earth Tech and Parsons.

The trend from the early '70s and '80s has been outsourcing manufacturing of microelectronics products overseas, although TI recently announced the opening a new manufacturing facility in Austin, TX. Irrespective of political initiatives to increase U.S. job opportunities, some companies such as TI are showing interest in expanding manufacturing capabilities in the United States out of shear necessity due to lack of quotas to build additional plants at their overseas locations.

Conclusion

Outsourcing in the water and wastewater sectors globally is a sensitive issue mainly when dealing with municipal facilities, but outsourcing in the industrial sector makes economic sense for most companies. Regardless of whether the parent company of these semiconductor manufacturers are American, European or Asian, their technology standards need to be matched to survive in this highly demanding market. This translates to need for the highest quality ultrapure water and bringing efficiency to the plant by water reuse, recycling and responsible disposal. With companies like Hynix, a Korean manufacturer partnering with Veolia Water North America (which has a French parent company), there are no limitations or boundaries in U.S.-based O&M companies expanding within North America and overseas. Industrial outsourcing originally thought to be a non-viable trend is slowly but surely changing.

About the Author: Usha Srinivasan is the Industry Manager for the North American Environmental Technologies Division at Frost & Sullivan Canada in Toronto. A report on this topic, "U.S. Microelectronics Wastewater Market," is to be published by Frost & Sullivan in 2005. For more information, call 416-490-0349 or visit www.environmental.frost.com.