Pharmaceuticals, Personal Care Products and Other Microconstituents: What Treatment Technologies are Working?

By Joseph G. Cleary

Microconstituents, including active pharmaceutical ingredients (APIs), are becoming a concern and are being evaluated by the United States Environmental Protection Agency (EPA) for future regulations. Some industries, such as pharmaceutical, have been proactive and already are implementing treatments to control microconstituents entering the environment. Municipalities are also studying the removal of microconstituents through treatment processes including what is contained in biosolids for land application and composting.

Microconstituents, the term developed by the Water Environment Federation (WEF), can make their way into the environment through a variety of routes, including industrial discharges, wastewater treatment plant (WWTP) effluent, runoff from agricultural and feedlot operations, and other nonpoint sources that are more difficult to quantify. Microconstituents are defined as natural and manmade substances, including elements and inorganic and organic chemicals, detected within water and the environment. Humans, aquatic organisms and other wildlife can be exposed to these compounds through environmental contact and consumption of certain foods and waters.

Microconstituents include a few sub-groups, one of which is pharmaceuticals and personal care products (PPCPs). The PPCPs include a large number of chemical contaminants. These can originate from human usage and excretion and veterinary applications. A variety of these products, such as prescription and over-the-counter medications, fungicides and disinfectants are used for industrial, domestic, agricultural and livestock practices (Ternes and Daughton, 1999).

There are also potential endocrine disrupting compounds (EDCs) that might be expected to lead to endocrine disruption in an intact organism. These potential EDCs include hormones, natural chemicals, synthetic pharmaceuticals and other manmade chemicals, including cosmetics and pesticides.

EDCs have received more attention in the media and technical literature in recent years. A review by the World Health Organization has concluded that low-level environmental exposure to Endocrine Disruptors has not yet been demonstrated to cause harm to human health (Damstra et. al., 2002). Uptake of Endocrine Disruptors by humans from treated drinking water is relatively low in comparison to other sources such as food (GWRC, 2003).

The fate of microconstituents, including the PPCPs and EDCs through municipal and industrial wastewater treatment plants, is driven mainly by their physical/chemical properties. Pharmaceuticals are complex molecules with different physical and chemical characteristics. They are notably characterized by their ionic nature, molecular weights between 300 and 1,000, and relatively low solubility (mg/L or less). Most pharmaceuticals exist as cations, anions or zwitterions, with only a limited number of compounds existing in neutral forms under the conditions encountered in the aquatic environment. They are designed to have specific effects within humans (for example, cardiovascular, central nervous system, antibacterial, anti-inflammatory, immune, anticancer). Many of these special properties are relevant to the assessment of their environmental fate and transport properties. (Williams, 2006).

Sorption is an important process that controls the distribution of pharmaceuticals between particles and water. Charged compounds, including many pharmaceuticals, typically undergo sorption by mechanisms that are different from those of neutral hydrophobic compounds. As a result, prediction of pharmaceuticals partitioning based on only hydrophobic interactions, Kow, will tend to overestimate sorption.

On the other hand, distribution coefficients, Dow, which accounts for partitioning of both unionized (hydrophobic) and ionized (hydrophilic) forms of a molecule, tend to underestimate sorption. The adsorption of pharmaceuticals to suspended particles represents a potentially important attenuation mechanism for many human pharmaceuticals in municipal WWTPs and in riverine or coastal waters.

Biodegradation often is the most important process by which organic chemicals are transformed in WWTPs and natural aquatic environments. In the case of human pharmaceuticals, volatilization and hydrolysis are normally of limited importance, making data on vapor pressure and hydrolysis rates potentially not as important (Williams, 2006).

The Water Environment Federation (WEF) has prepared a technical practice update (TPU) called "Effects of Wastewater Treatment on Compounds of Potential Concern" (WEF, 2007). The TPU specifically examined the effect of wastewater treatment on some of the known or suspected microconstituents and the potential treatment technologies for their removal at WWTPs based on a survey of the literature.

The TPU states that, with our ability to detect increasingly low compound concentrations, targeting 100 percent removal of microconstituents from WWTP effluent is not realistic. Rather, the goal should be reduction to levels with no adverse environmental effects, although these levels are presently difficult to define.

Biological Treatment

Activated sludge treatment configurations such as the Modified Luzack Ettinger (MLE) Process and membrane bioreactors (MBR) are being used more now in both industrial and municipal wastewater treatment plants. These biological treatment technologies are being used now versus the more traditional activated sludge, sequencing batch reactor (SBR) and trickling filter technologies for nutrient removal and to produce higher quality effluent water for recycle and reuse. There is some synergy in goals as nutrient removal plants, with increased sludge age, should achieve increased removal of the microconstituents that are biodegradable.

Some EDCs are theoretically fully biodegradable. Johnson and Darton (2003) state that the EDCs generally implicated in endocrine disruption in fish (i.e., the estrogens E1, E2, EE2 and nonylphenol) are all "inherently biodegradable and so in theory should not present an intractable problem." Many studies have demonstrated that some activated sludge processes have the potential to remove a large fraction of several suspected EDCs, often to below detection limits (Ying et al., 2002). The amount of EDC removal achieved depends on both the characteristics of the wastewater and the processes in place at the WWTP.

Researchers have found that solids retention time (SRT) in an activated sludge system has a pronounced effect on removal of some EDCs (Joss et al., 2004). Solids retention time has a major influence on biological degradation efficiency, which is mainly due to its influence on the diversity of the microbial population and on the multitude of degradation pathways being expressed. Philips et al. (2005) noticed marked improvement in EDC removal as SRT increased from 5 to 10 days. It appears that SRTs of 10 to 15 days may result in more effective removals (Seigrist et al., 2005; Ternes et al., 2005). Each WWTP and wastewater is unique, however, so the degree of EDC removal will be site-specific.

One case study project included evaluation of full-scale plant sampling of four microconstituent compounds at two activated sludge plants in Europe. The physical/chemical characterization was input to a process model to compare predicted performance versus actual full-scale performance. Two of the compounds were highly biodegradable and one, an antifungal compound, was not. Partitioning or adsorption to sludge based on the octanol-water coefficients was minimal, and this correlated well with the full-scale performance.

The STPFATE9 model (Mueller, 1995) was used to determine the impact of increasing the sludge age on the fate through one of the treatment plants. Based on measured data of the concentrations of these organics in the influent, effluent and sludge, a previous evaluation determined that the major removal mechanism was biodegradation with negligible removals occurring through sorption.

Volatilization losses were assumed to be zero. The biodegradation losses were computed to be approximately 66 and 73 percent for the two compounds. For the STPFATE9 analysis, the treatment plant was simulated by setting the plant's physical dimensions and operating conditions (i.e., BOD removals, flow, solids, tank volumes, etc). The measured influent concentrations, chemical-specific octanol-water partition coefficient and biodegradation rate constants were inputted to simulate the measured sludge concentrations (i.e., sorption losses) and biodegradation losses (i.e., computed values).

The plant was calibrated to a 15-day SRT, which is the condition the plant is currently operating under. Once all the conditions were set, the SRT was increased to 30 days and the impact on the biodegradation was determined. The result was an increase in the biodegradation rate by 14 percent. The percent removed by biodegradation increased from 66 to 75 percent for one compound and 73 percent to 83.5 percent for the second compound.

Advanced Oxidation

Advanced oxidation processes are combinations of Ultraviolet light (UV) plus hydrogen peroxide, ozone plus hydrogen peroxide, and UV plus ozone that are specifically designed to increase the formation of powerful hydroxyl radicals to oxidize microconstituents. Ozone shows similar potential as Advanced Oxidation Processes (AOPs) for microconstituent removal and is often included in AOP discussions.

Substances that are difficult to biodegrade may be oxidized by AOPs, and the oxidized byproducts may be more amenable to biodegradation. Advanced oxidation processes can be followed by a biological process to further degrade the byproducts; or, natural purification processes may be relied upon for treatment, depending on the situation (Ried and Mielcke, 2003).

The results of a two-stage MBR and ozone treatment pilot study (Helmig, 2005) showed removal of active pharmaceutical ingredients (APIs) through MBRs but still some residual concentration which was further destroyed by ozone treatment to non-detect concentrations. Estrone was still present in the effluent after ozone treatment.

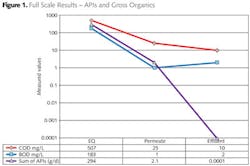

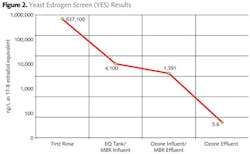

Full-scale performance for this MBR plus ozone treatment plant showed a 1,000 fold reduction in estrogenicity using Microtox™ test as 17B estradiol equivalents (Helmig, 2009). The total APIs removal was 99.94 percent. The full scale operating plant demonstrates that these technologies are proven at full scale. Figures 1 and 2 show the API and estrogencity removals, respectively.

Another pharmaceutical company was planning to add a new anti-microbial type product from a European plant. The company was concerned that based on its structure and physical/chemical characteristics the compound to be added to the wastewater is non-biodegradable and would pass through the treatment system to the effluent. The compound was found to be toxic to fish. Treatability studies were performed to evaluate Advanced Oxidation Treatment (AOT) processes, including UV/hydrogen peroxide, catalyst/UV/hydrogen peroxide, UV/ozone and UV/hydrogen peroxide. The tests results showed both compound destruction and aquatic toxicity reduction. All four technologies were effective at destroying the compound by over 99 percent, However, the toxicity reduction was variable and most likely due to creation of breakdown products in the reactor. The highest toxicity reduction of 99.1 percent was achieved with UV/ozone treatment.

Other Technologies

Other technologies which have been shown to remove microconstituents and pharmaceuticals include ultrasound, ultrafiltration/reverse osmosis and carbon adsorption (Cleary, 2011).

Alternatives Analysis Approach

The following approach is proven and recommended to evaluate and compare treatment alternatives for microconstituents, including active pharmaceutical ingredients (APIs) and insecticides. This approach is based on understanding the physical/chemical characteristics of the microconstituents to be treated or controlled and their fate or removal through various treatment processes. This understanding can be developed through the use of the following approach and sequence of work tasks.

• Review of physical/chemical properties which impact a microconstituent's behavior through treatment processes (i.e., biodegradation, volatilization, adsorption, etc.)

• Benchmark comparison of treatment alternatives and costs through available literature

• Use of predictable modeling tools to predict the fate or removal through existing and proposed treatment systems

• Use of desktop alternative analysis to compare alternatives based on cost and non-cost criteria

• Use of bench-sale treatability studies to further refine the desktop alternatives comparison and cost comparison

• Use of pilot studies to further refine process design and expected treatment performance over a period of time and variability in loading conditions

The physical and chemical properties are critical to using the process modeling tools to predict performance through treatment. The treatability study or full scale sampling data then can be used to calibrate the models and subsequently used to predict performance with optimization of the treatment process (i.e., increased sludge age) or adding additional treatment capacity or processes.

Conclusions

• There are proven treatment technologies to remove microconstituents based on pilot and full-scale treatment data. These include biological treatment, advanced oxidation processes, carbon adsorption and ultrasound.

• EDC removal in POTWs and industrial wastewater plants varies based on the wastewater physical/chemical properties of the microconstituents present and the process design operating parameters such as sludge age and temperature for biological processes and ozone and hydrogen peroxide dosages and reaction time for ADPs

• Treatability studies can be used for site-specific wastewaters to evaluate treatment processes, determine effluent concentrations as well as toxicity, and develop process design criteria

• For the majority of the studies reported and our experience, biodegradation and partitioning to the biomass are the two key mechanisms for destruction and treatment in POTWs and industrial wastewater systems

• Ozone in a proven technology at full-scale in the pharmaceutical industry as a polishing step after biological treatment

• Estrogenicity and API was greater than 99.9 percent reduction using MBR plus ozone

About the Author: Joseph G. Cleary, P.E., BCEE, is Senior Vice President, at HDR|HydroQual, Mahwah, NJ. He has over 35 years of experience in environmental engineering consulting, specializing in industrial wastewater treatment and hazardous waste remediation.