Pumping the Unknown: Anticipating and Planning for Pump Purchase Needs

Staged. High head. High flow. High efficiency. Solids handling. Non-clogging. What’s the best way to cut through a maze of company claims and pump characteristics when developing a new application... or revamping an old one? For an answer, look at the past and get a good feel for what has proven successful in similar situations. Then, collect data on the present conditions - and incorporate plans for the future.

Whether developing a completely new pumping system or updating an old one, reviewing the history of similar systems will go a long way to success when facing the unknowns. Often, it’s surprising to see that what’s expected from a system isn’t what actually happens. Whether caused by the pipe friction coefficient affecting actual vs. calculated head, the recovery head or lack of expected recovery head, or any other reasons, the pump must be able to function properly under the new actual required conditions. Obviously, the more experience you have at your fingertips to draw on... the fewer surprises.

Garbage In, Garbage Out

Collecting data for a new system is probably the most important step of the process. Generally, the length of pipe and number of fittings is fairly easy to determine. When pumping sewage out of a wet well, the flow may be determined by the expected inflow - or by how often the pump needs to cycle to keep from going septic. Or, a minimum velocity may be required to keep solids moving through the discharge piping.

As the old adage goes, “You may not be able to choose your parents, but you can do the best with what you’ve got.” In pump terms, there’s usually little that can be done about changing the flow range, since it’s most likely established by other factors. Likewise, the pump site designer often can’t avoid the ups and downs of the terrain that the force main must traverse. How well placed and how well the siphon breakers and air release valves function (and remain functioning) can greatly affect head requirements over the life of the pumping equipment.

A well designed pump can have a life expectancy of 50 years or more. To take advantage of that feature, though, it’s important to look as far into the future as possible. While initial installation is costly, prudent designers will forecast the long-term future to come up with a pumping system that can easily be upgraded as the operation grows, avoiding even costlier revamping. In fact, some progressive companies have actually buried a second parallel main that may easily be tied into an existing line as significant additional flow is needed. This preplanning effort will avoid the future ongoing costs of friction energy loss and the problem of too large of a pipe to keep solids in suspension.

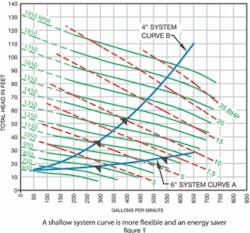

But even the best laid plans can fail. That’s why it’s so important to work with a consultant, pump distributor or company that can add to the circle of experience on a project. These partners can also direct your team to the most flexible pump available to accommodate the range of conditions an actual system might experience. The following examples will help to illustrate this point. But first, as a reminder, a relatively shallow system curve will allow significant flow changes with relatively little speed change (In Figure 1, note the capacity increase in Curve A of 250 gpm with a 300 rpm increase in speed and about 4.5 hp more power required. Compare that with Curve B, where the same 300 rpm increase yields only 100 additional gpm and requires 5 additional hp.). Also, remember that in the pumping world, friction is bad. Using speed to overcome large friction forces should be avoided as much as possible to attain the greatest economy over the life of the pump.

The Power of Experience

Traditionally, solids-handling, self-priming pumps have been designed to operate at relatively low heads (around 100 feet or less). Therefore, for every 100 feet of elevation increase or for long discharge lines with high friction, a new pumping station will be required. While most pumps can be run at higher speeds to get additional head, they become increasingly noisy - and eventually run out of practical mechanical capacity.

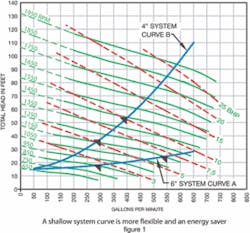

The need to meet the growing demands of expanding operations and the desire to use increasingly more demanding topography were identified by The Gorman-Rupp Company. To meet these new demands, a series of pumps have recently been developed (The Ultra VTM) that can operate at higher speeds without the associated noise, while maintaining many of the traditional features that users have come to expect from their high performance pumps. At the same time, this new line of high performance pumps have a broadened performance envelope, allowing for the surprises mentioned earlier in this article. Figure 2 V4 Performance is an example of how the Figure 1 T4 Typical 4” Performance curve has expanded.

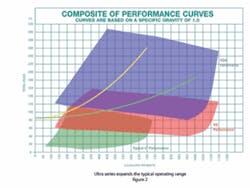

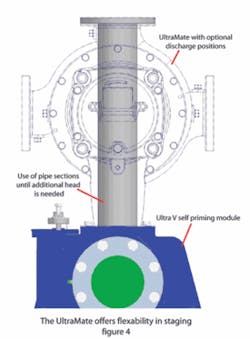

In conjunction with the new pump series, a more convenient method of staging two pumps was developed for applications beyond the capability of a single pump. Previously, conventional staging consisted of setting two pumps side by side and running plumbing from the first stage discharge into the suction of the second stage. While some friction loss does exist when pumping from stage one to stage two, the real problem revolves around necessary floor space required, and challenges involved in installing piping. To solve these, an innovative transition casting is now available that allows for a straight centrifugal pump (the UltraMateTM) to be mounted directly on top of the Ultra V’s lower module self-priming pump discharge (see Figure 3).

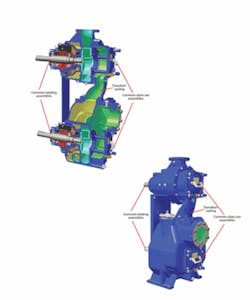

With the exception of the transition piece and volute scroll, all major components are common to both pump units. Since plumbing convenience is also a major consideration, the UltraMate volute is designed to rotate to different positions (see Figure 4) - thereby better accommodating a variety of discharge header configurations where multiple pairs are going to a common header. When one pump will satisfy the system for a reasonable length of time, a section of pipe can be plumbed into the system in place of the second stage pump until that additional investment must be made (see Figure 4). With this alternative staged configuration, end-users can now experience two and one half to three times the head that has previously been available with the conventional single stage pump (see “VS4 Performance” in Figure 2). Also the broader operating range allows for more “wiggle room,” for when actual performance doesn’t meet the design.

Conclusion

Regardless of the configuration or pump innovation being enlisted for any given challenge, it’s important to stress the amount of care and attention to detail that must be exercised in designing a total pump system. Remember that friction continues to be the most expensive element in a design. It not only requires larger motors and controls, but it also robs the user of expensive electrical power each and every time it runs. Again, careful projections and planning will pay dividends in the end when developing mindful of the future.

About the Author: A registered professional engineer, Dave Meister is engineering director of the Gorman-Rupp Co., a Mansfield, OH-based manufacturer of pumps and pumping systems for water, wastewater and sewage applications in municipal, industrial, construction, petroleum, fire and OEM markets. Contact: 419-755-1011 or [email protected].