Turbidity - Clarifying Low-Levels

Over 10 years, the analysis of turbidity has become far more than a measure of water clarity. Now, low-level turbidity analysis is becoming a method of choice for protection against emerging pathogens such as Cryptosporidium and Giardia. By assuring proper water filtration, risks from a variety of undesirable contaminants in our nation’s water supplies can be reduced.

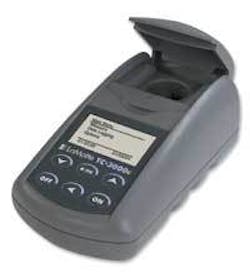

In 2002, the EPA published the Long Term 1 Enhanced Surface Water Treatment Rule (LT1ESWTR) mandating turbidities in combined filter effluent to read at or below 0.3 NTU. The EPA hoped this action would achieve a 2-log (99%) removal of Cryptosporidium. Talk now is of lowering this to 0.1 NTU. To achieve the EPA’s goals, constant turbidity monitoring of filtered water is critical. This monitoring is often accomplished with on-line turbidity meters at water treatment plants and portable instruments in the field. The trend has been to check calibration of on-line turbidimeters with either bench-top or handheld field turbidimeters using precision standards created to meet EPA specifications.

Turbidity measurement

Before venturing too deeply into the topic of water clarity, it makes sense to discuss basic principles of turbidity measurement. Turbidity is an aggregate property of water. It’s caused by suspended particles in water. It isn’t specific to the type of particle in the water and the particles can be suspended or colloidal matter, as well as inorganic, organic or biological. At high concentrations, turbidity is perceived as cloudiness, haze or an absence of clarity in the water.

Turbidity analysis is an optical measurement of scattered light. When light is passed through a water sample, particles in the light path change the direction of the light - scattering it. If the turbidity is low, most light will continue in the original direction. Light scattered by the particles allows particles to be detected in the water, just as sunlight can illuminate dust particles in the air.

A turbidimeter is a meter that measures turbidity. Measuring low-level turbidity requires precisely quantifying light scattering in water using a turbidimeter that’s also a nephelometer. The terms nephelometer and turbidimeter are often used interchangeably, but a nephelometer specifically measures light scattered at a 90° angle to the light beam. Light scattered at other angles may also be measured, but the 90° angle defines a nephelometric measurement. The light source for nephelometric measurements can be one of two types to meet EPA or ISO specifications. The EPA method specifies a tungsten lamp, with a color temperature of 2,200-3,000 °K. Measurement units for the EPA method are recorded as nephelometric turbidity units (NTU). The ISO method specifies a light emitting diode (LED), with a wavelength of 860 nm and a spectral bandwidth less than or equal to 60 nm. Measurement units for the ISO method are formazin nephelometric units (FNU).

Use of portable handheld nephelometers to check calibrations of on-line turbidimeters/nephelometers requires handheld meters to have meticulously designed optical systems. These meters must be capable of stable, long-term calibrations, high precision and accuracy, and low detection limits. Even with a well-designed meter, measurement technique is critical to obtaining accurate and precise low-level turbidity readings. Measurement techniques include selection and use of sample tubes, minimizing stray light interference, and proper sample handling.

Tube selection

Selection and handling of tubes is of utmost importance. Tubes may occasionally need to be soaked in a dilute HCl solution before washing. They should always be washed on the inside and outside with mild detergent prior to use, to remove dirt or fingerprints. They should be rinsed 5-10 times with turbidity-free water. They should then be allowed to air-dry in an inverted position to prevent dust from entering. Clean, dry tubes should be stored with caps on to prevent contamination. Before use, tubes must be clean and free from lint, fingerprints, dried spills and scratches. Scratches are especially a problem if located where the light beam enters or exits the tube. Any scratched tube should be discarded.

After a tube is filled and capped, it should be held only by the cap to avoid problems from fingerprints. When setting a filled tube aside make sure it’s placed on a clean and dry surface that won’t contaminate it. Before being placed in the instrument, the outside surface of the tube should be wiped with a clean, lint-free absorbent cloth, until it’s dry and smudge-free. This is imperative for precise readings and will keep the light chamber in optimal condition. Tubes should be emptied and cleaned as soon as possible after reading a sample to prevent deposition of particulates on the inside and caps. For highly accurate results, errors from contamination can be reduced by designating tubes and caps for use only on very low turbidity samples, while others are reserved solely for very high turbidity testing.

Some manufacturers suggest lightly coating the outside of tubes with silicone oil to fill in tiny scratches and minimize stray light associated with imperfections in the tube. Applying consistent amounts of silicone oil is a challenge, however, and small variations can cause large changes in the refractive index of the tubes. This can result in substantial changes in turbidity readings, so many manufacturers warn against silicone oil use. There are other more reliable methods for minimizing stray light.

Stray light reduction

Stray light is light that’s detected but isn’t directly scattered from turbidity in the water sample. Interference from stray light will cause high readings. Stray light can come from electronic noise, internal reflections within the optics, and stray reflections from dirt and dust in the meter chamber. Scratches, fingerprints and water droplets on the tube also can cause stray light interference, leading to inaccurate results. Contemporary turbidity meters, equipped with microprocessors, eliminate electronic noise by subtracting out a sample reading with the light source turned off. Turbidimeters with a blanking procedure can eliminate stray light associated with internal reflections. The blank should have the same interference, due to internal reflections, as the sample and is subtracted from the sample reading to remove this source of stray light interference. If the same tube is used for the blank as for the sample, and is properly indexed in the chamber, stray light interferences due to tube imperfections can be minimized.

Another source of stray light is molecular scattering of light by the water molecules themselves. Dissolved molecules, including very small sub-micron particles that can’t be filtered out, also will scatter light. This molecular scattering of light has been estimated at 0.01-0.02 NTU. For this reason ultrapure water can still cause light scatter and is thus often called low turbidity water. It can be argued using a blanking procedure can eliminate stray light effects from molecular scattering. If water properly filtered through a 0.1 micron filter can be considered turbidity free because there are no undissolved particles in the water, then any stray light must be from molecular scattering. This stray light can be compensated for with a proper blanking procedure on an instrument with high quality focusing optics to obtain a result of 0.00 NTU.

Conclusion

In the first part of this article, we’ve discussed tube selection, stray light reduction and molecular scattering. In the second part, we’ll discuss negative results, sample handling and calibration.

About the Author: James W. Egan Jr., PhD., is R&D chemist for LaMotte Company. Based in Chestertown, MD, LaMotte sells and manufactures equipment for testing water, soil and air. It services the pool & spa, environmental science, aquaculture & aquarium, industrial wastewater, drinking water, soil testing, and home science markets. Refer to author for article references. Contact: 800-344-3100 or www.lamotte.com