A solid solution

Anaerobic treatment eases sludge and energy use in U.S. industrial plants

An anaerobic wastewater treatment system designed to reduce or eliminate high-strength biochemical oxygen demand (BOD) and chemical oxygen demand (COD) discharges is being introduced to the U.S. industrial market. The system, developed and operating in Europe, continuously converts BOD, COD and sludge in wastewater streams to biogas, which can be subsequently used as a secondary energy source.

Beckart Environmental, an American engineering firm specializing in wastewater treatment technologies, plans to manufacture a fleet of low-cost bioreactors developed by Econvert, a Dutch company specializing in anaerobic wastewater treatment.

Beckart partnered with Econvert to provide customers producing effluent with high levels of BOD and COD an effective anaerobic solution to minimize costs/surcharges and waste attributed to using an aerobic system.

Sid Embree, a sales advisor for Beckart and Econvert, explained that these systems are ideal for facilities in locations where municipal sewage treatment charges are high and are continuing to rise.

"These charges are increasing in several U.S. states and municipalities as jurisdictions need to pay to upgrade and/or expand older municipal treatment systems. Depending on BOD (and COD) charges, systems can have a payback as low as 1½ to 2½ years," she said.

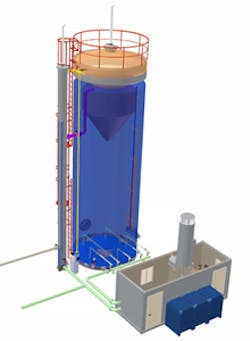

The reactors are proven to reduce BOD and COD in wastewater by 80 to 90 percent and can be retrofitted into existing aeration systems, helping facilities reserve energy- and installation-related expenditures. Econvert's systems also feature a unique vertical design ideal for reducing floor space requirements.

"With the anaerobic system, we utilize height on the large reactors, and it doesn't require as much retention time, so it'll typically be 20 percent of the space of an aerobic system," said Dan Fedrigon, vice president of sales and marketing at Beckart. "A lot of facilities don't have the space to go anaerobic, so they just keep paying the surcharges. This system can go in and reduce the surcharges and pay for itself."

Econvert's bioreactors are primarily used in large paper mills, breweries, food processing plants, and beverage manufacturers to treat wastewater and convert BOD and COD into biogas.

"If you have enough waste, you can make enough biogas that can be reused so you have an ongoing benefit of being able to produce some of your own energy," said Fedrigon. "You can take the biogas, clean it up, and you can power a boiler with it for example."

"Anaerobic wastewater treatment is important for a few reasons," said Embree. "First, it creates energy (biogas) that can be used to substitute some natural gas or other fuel used in an industrial facility's operations. Finally, the systems do not require much attention, typically an hour or two per day for monitoring and data collection."

In order to achieve optimal BOD and COD concentrations, the expanded granular sludge bed (EGSB) wastewater digestion reactor mixes influent with recirculated effluent. Biogas is created and sludge is reduced from properly adjusted wastewater up-flow speeds. The facility's fuel system collects the produced biogas, where it can be used to generate energy or be resold.

Other features include an internal recirculation (IR) reactor and an up-flow anaerobic sludge bed (UASB) characterized by a 3-phase modular settling system that allows effective separation of the effluent, biomass and biogas.

A full range of sizes are available for variable loads and are suitable for those from approximately 660 lbs COD/day or 440 lbs BOD/day. Further, individual systems can treat up to 52,000 lbs COD/day. Standard features include a gas-tight reactor, a congestion-free influent system, a recirculation pipe to minimize odor, and a modular approach for increasing flows at expanding facilities. The system also features adjustable, independent upflow configurations and touch-screen controls panels.

"The long-term benefit is essentially a system that should, over a two- to four-year period -- depending on the application -- have a 100 percent payback," said Fedrigon.

Beckart is currently quoting customers and is expecting to manufacture Econvert's technology this year with plans to install the first U.S.-based system in 2014.