Handling Harmonics with AC Drives

By Rick Hoadley

Pumping and mixing motors are becoming abundant in industrial wastewater facilities as systems expand to keep up with population growth and demand for more water, distributed over larger areas. To maintain water pressure and control flow, adjustable speed drives are a valuable companion for these AC motors.

Drives are an efficient alternative to throttling values, as they match power needs and motor speed to the demands of varying flow. Drives can save energy and electrical costs, increase pressure reliability, reduce cumbersome pump changes and lessen damage to mechanical equipment. However, as drives are boosting efficiency and reliability, they might also be contributing to power quality problems, such as line current and voltage harmonics.

Harmonics are deviations from the sinusoidal fundamental AC line voltage and current. Most electrical power in North America operates at a frequency of 60 hertz. A harmonic frequency is an integer multiple of this fundamental frequency. So in a 60-hertz system, the second harmonic would be 120-hertz, the third would be 180-hertz, and so on. The addition of any harmonic to the sinusoidal fundamental current or voltage will create distortion. The greater the amplitudes of the harmonics present, the greater the distortion in the electrical waveform. Very simply, whenever a voltage or current does not look like a perfect sinusoidal waveform, it contains harmonics.

Compared to DC motor drives, AC motor drives cause very few problems. However, poorly designed applications can result in power line voltage distortions. These voltage distortions can cause problems for other equipment connected to the same power lines – resulting in erratic operation of controls, dimming of lights, audible noise on telephone systems, and static on AM and FM radios. The distribution transformers and cables feeding these drives will also experience additional heating, which reduces the power utilization of those components.

What Causes Harmonics?

Unlike an AC motor operating across the power line, the current drawn from a distribution transformer feeding a typical AC drive is far from a sinusoidal waveform. This occurs because the drive is taking current from the transformer only during certain times of the cycle to convert the AC line voltage to a fixed DC voltage within the drive. The drive then pulse-width-modulates this fixed DC voltage into variable frequency, variable voltage for the motor. The AC-to-DC conversion is what causes the harmonics. Current flows only during part of the cycle and is off during other parts of the cycle, creating the odd-looking current waveform. It is this distorted current that creates the voltage distortion.

As the number of drives employed in automation systems grows, so too does the misconception that drives are the only piece of the puzzle to harmonic problems. While they may comprise a sizable portion of non-linear loads, they are only one element in the harmonic equation. That's why it's important to analyze all electrical loads that could potentially cause problems for a system before making any final conclusions.

How Much is too Much?

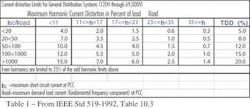

When other equipment is connected to secondary power terminals, voltage distortion may cause improper operation of the other equipment. So, how much current harmonic distortion will cause a problem? The Institute of Electrical and Electronic Engineers (IEEE) Std 519-1992 recommends maximum current distortion levels caused by non-linear loads to limit the voltage distortion they would create, minimizing the likelihood of equipment failure due to those harmonics.

To predict if a particular plant or system consisting of drives, motors, heaters, lights and other equipment may have problems, only three pieces of information are needed:

a. Isc, short-circuit current of the transformer feeding the system. Isc = kVA x 1000/(Vsec x 1.732 x Z) where kVA is the rating of the transformer feeding the system, Vsec is the secondary line-to-line voltage of the transformer, and Z is the decimal impedance of the transformer (in other words, 5.3 percent translates to 0.053). All of this information is typically found on the transformer nameplate.

b. Ifund, total fundamental current load on the transformer.

The fundamental current of a drive is typically 1.1 x hp for a 460V drive. The fundamental current of a motor running across the line is typically 1.2 x hp for a 460V motor. The fundamental current of a 460V linear load is 1.25 x kW. Simply double the values for 230V systems. Add all of these fundamental currents together to obtain a total fundamental current at maximum load.

c. Iharm, total harmonic current load on the secondary transformer. This is usually a difficult number to obtain. Iharm can be estimated by multiplying the Ifund for the drive by the percentage given below.

• six pulse drive without a link choke: 80-120%

• six pulse drive with a link choke: 30-40%

• 12 pulse drive: 8-15%

• 18 pulse drive: 4-6%

• Synchronous converter: 3-5%

What do we use these numbers for?

Take the ratio of Iharm / Ifund to obtain the current Total Demand Distortion (TDD). This is the harmonic current divided by the fundamental current or the total harmonic distortion at maximum load.

Next, find the Isc/Iload ratio by taking Isc / Ifund. Go to Table 1 and find the corresponding range in the left-hand column titled Isc/Iload. Then see if the calculated TDD is less than or equal to the right-hand column of the TDD values listed in that table for that Isc/Iload ratio. If the calculated TDD is less, than there should be no harmonic issues at that site.

What Affects Harmonic Current?

The harmonic current created by the drive can be affected by the presence of a DC link choke, the DC bus capacitance and the line inductance between the drive input and its source of voltage; such as transformer inductance, cable inductance and additional line reactors.

The closer you are to the drive, the greater the voltage harmonic distortion. This is why the voltage distortion is greater at the drive than at the transformer. If other equipment needs to be connected to the same transformer as the drive, connect the other equipment as close to the transformer as possible. This will minimize the effect of the current harmonics produced by the drive on the voltage waveform, which can cause problems with the other equipment.

Reducing Harmonics

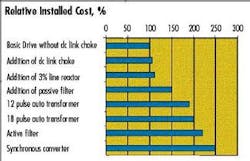

There are several methods and products to reduce the line current harmonics created by drives. Cost is not the only factor that distinguishes one solution from another. Even though the addition of line reactors or passive filters can help reduce the current harmonics, they will also reduce the DC bus voltage within the drive at full speed, full load conditions. This will prevent the drive from being able to provide full power to the motor, limiting the power out of the motor to about 95% of its nameplate rating.

Why would you install a 100 hp motor only to have its capability limited to 95 hp, especially under peak demand conditions? This is why multi-pulse solutions are a better fit for most situations, since no derating is necessary and it is less expensive than other mitigation methods.

Harmonic Mitigation Methods

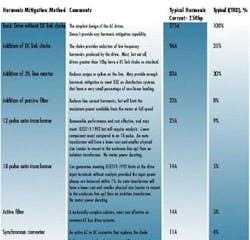

For a 250 hp drive, the chart above details the typical harmonic current, I(THD), and relative installed costs associated with various harmonic mitigation methods.

(For simplicity, we will say that the 250hp drive is connected to a supply with a short circuit capacity of 60,000A, will draw 260Arms of fundamental current for its load, and will have a cost of 100%.)

The goal for those specifying harmonic mitigation solutions is to combine the most cost effective solution for the particular drive and power distribution system. Since several factors come into play in determining the harmonics in the drive system, the engineer needs to consider all factors before arriving at a final recommendation.

About The Author: Rick Hoadley is the Technical Program Manager in the Engineered Drives Business at Rockwell Automation in Mequon, WI. He has been active in the development and application of adjustable speed drives for more than 28 years.