Biottta™ biotreatment packaged plants for municipal drinking water

Aug. 25, 2014

2 min read

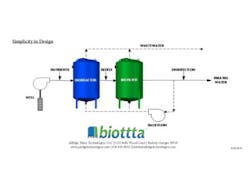

Groundwater is the primary water source for most communities in North America. With an increasing need to provide treatment for a growing list of contaminants, limited support staff and shrinking operating budgets, water utilities face many hardships. Fortunately, biottta™ leverages nature to offer an affordable and sustainable solution for wellhead treatment of inorganic and organic contaminants. The fixed-bed, dual stage biotreatment cultivates a robust environment for microbiological organisms to destroy contaminants or reduce elements to simple, non-harmful forms. Developed specifically for drinking water applications, the fixed-bed treatment process consistently addresses contaminants at low levels, intermittent or fixed operation, and the dual-bed assimilates a complete packaged biotreatment plant with a dependability required for protecting public health.

Why choose biottta™?

One solution

Biottta™ has regulatory approval for the reduction of nitrate and perchlorate and demonstrates hexavalent chromium, VOCs, iron, manganese and sulfide elimination in a single process.

Sustainable

Biottta™ is a low energy treatment process that eliminates contaminants from the environment rather than creating a concentrated waste stream. The low volume discharge of the biottta™ process is easily managed as a non-hazardous waste stream.

Operator friendly

The biottta™ package does not require extensive operator attention or experience.

Affordability

When compared to ion exchange or membrane treatment processes, biottta™ is the lowest cost solution for the removal of co-contaminants.

About the Author

Sign up for our eNewsletters

Get the latest news and updates