A Midwest packing plant produces ready-to-eat pork breakfast sausages in a continuous process that includes blending the meat and spices, stuffing the casings or forming the patties, cooking the sausages, packaging them and finally freezing the product. Clean process is used at each step of the process, but it’s the final freezing step that offered a challenge to the plant’s industrial water professionals.

That final critical step is accomplished in a sophisticated 1,000-gallon-per-minute (gpm) waterfall pouch chiller using a mixture of water and food-grade propylene glycol at -5°F. The temperature of this mixture must be maintained within a very narrow range to meet strict food safety regulations.

The filtration challenge

When the water/glycol mixture comes into physical contact with the packaged product, Murphy’s Law takes effect and packages occasionally break, which releases bits of sausage and packaging materials into the process fluid stream.

The packer originally equipped the chillers with bottom-mounted screens to catch any bits of sausage and packaging materials that may get into the liquid and keep them out of the heat exchangers. If and when the screens get clogged, the flow of water/glycol through the heat exchangers is reduced and the temperature in the processing area rises. If the temperature exceeds the food safety limit, the entire batch of sausage and the now potentially contaminated glycol/water mixture must be discarded.

"If the temperature [in the processing area] exceeds the food safety limit, the entire batch of sausage and the now potentially contaminated glycol/water mixture must be discarded."

Even though the plant was spending $40,000 to $60,000 per year cleaning the sumps and screens to maintain the chillers, it still experienced an over-temperature event every four to six months on average at a cost of $20,000 per incident just to replace the process fluid. Because the process had to be shut down every time the chillers were cleaned, plant managers were faced with a choice between the cost of lost production for maintenance and the cost of contaminated product and process fluid from an over-temperature event.

The solution: A more effective filtration system

Since the difficulties centered on the water/glycol mixture, the plant’s industrial water professionals were tasked with finding a solution. The situation called for a more effective filtration system, but handling the 1,000-gpm flow of glycol/water through the system presented an unusual challenge — and so did management’s requirement for a solution that did not require the system to be shut down for filter maintenance.

They considered a multi-filter system with enough extra capacity to handle the flow while one of the filters was offline for maintenance, as well as a self-cleaning filter that did not require downtime for maintenance. While the self-cleaning filter offered significant cost benefits, the volume of glycol/water that needed to be filtered was greater than the capacity of then-available standard models.

The plant’s water team contacted Crane Engineering in Kimberly, Wisconsin, a distributor of Eaton filtration products, to explore a range of solutions. After evaluating the application and its challenges, they recommended pursuing the self-cleaning filter alternative as the best long-term solution.

Eaton’s filtration system on glycol chiller

To prove the feasibility of the concept, Crane installed an Eaton self-cleaning filter on a side stream in the plant. In several months of operation at maximum flow, the filter, rated for 60 gpm, never clogged or required maintenance.

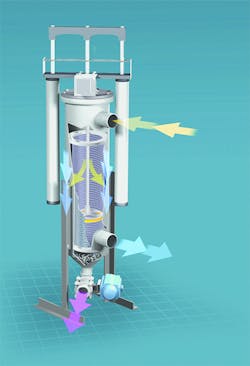

The filter uses a cylindrical stainless steel housing to hold the filtration media. Fluid enters inside the element and flows through it to the outlet, depositing any contaminants on the inside wall of the element.

A spring-loaded cleaning disc moves up and down to wipe the filter element clean and deposit contaminants at the bottom of the housing out of the flow path. Cleaning frequency can be based on time, differential pressure, manual selection or any other application-specific criteria. Because it remains in service while being cleaned, the filter satisfied the plant’s no-maintenance and no-downtime requirement.

The next hurdle was to find a second, much larger self-cleaning filter that could handle 1,000 gpm of water/glycol fluid.

With the filter still under development, Crane obtained one of the first production units and installed it in the packer’s chiller circuit. This filter is rated at 1,100 gpm, is 8 feet tall and weighs 720 pounds when fully flooded. It uses slotted wire strainer elements ranging from 50 to 1,140 microns to meet a broad range of application requirements.

The unit installed on the packer’s chiller uses a strainer suited to the exact specifications to provide minimum flow restriction. Its output is routed through another filter for final "belt and suspenders" cleaning before entering the heat exchanger.

How the filter system works

Filtration results

The installed filter ran for 3.5 years with no maintenance and no downtime. The packer still uses the screens at the bottom of the chiller to backstop the system, but they no longer plug up because the filter keeps the entire water/glycol stream clean.

The packer has since installed additional Eaton filters on similar systems in two of its other packing plants. The industrial water team is also evaluating the purchase of a corporate backup filter to have a plug-and-play solution in-stock for any future downtime if the filters now in service require maintenance.

Jim Lago is a regional sales manager for the North-Midwest region at Eaton’s filtration division. He is a filtration specialist with more than 31 years of experience in diverse industrial filtration applications, and he has covered various regions in the U.S. and Canada. Lago can be reached at [email protected].