Valve Innovation Assists Hanford Nuclear Waste Cleanup

Liquid wastes being stored at the U.S. Department of Energy's Hanford Site in Hanford, WA, are mostly water with radioactive solids deliberately mixed into a slurry for treatment.

These wastes are the legacy of 45 years of plutonium production by a facility on the frontline of America's nuclear weapons deterrent during the Cold War. The overall cleanup project is expected to take 10 years and cost $5.7 billion, currently the federal government's largest single domestic capital construction project.

The project, being overseen by Bechtel, is crucial because the site lies near the Columbia River, putting at risk the river's habitat and health of millions of residents living downstream.

"We had to be flexible in what we were offering to Bechtel to meet their requirements," says Larry Shields, senior sales engineer, Flowserve Flow Control.

Managing for Bechtel's various requirements for the Hanford Waste Treatment Plant (WTP) valves and actuators was a delicate balancing act for the Flowserve team, forcing it to innovate on the valve's design and which actuators would be used to control the valves.

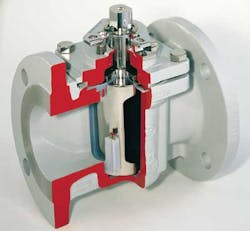

Flowserve is supplying two styles of valves and valve automation packages. The "bulge valves" are all stainless steel Mach 1 plug valves that have ultra high molecular weight polyethylene seals and will be located inside a double containment vessel called a "bulge." Each bulge valve will have a stainless steel stem extension connecting it with either a manual operator or a standard aluminum actuator located outside the bulge containment vessel.

The jumper valves are made of the same materials with stainless steel actuators mounted directly to the valves. The jumper valve assemblies will be located inside the high radiation "Canyon" areas of the waste treatment building. Each component has been modified with special materials selected to resist erosion, corrosion and/or radioactive degradation for the working life of the Hanford WTP.

Additional design modifications were also made to permit robotic servicing and repair of each component.