Bedrock Automation announces turnkey solution for underground injection pressure reporting at the wellhead

Bedrock Automation, the maker of Bedrock OSA, a powerful and secure industrial control system, announced the availability of a secure solution for automated remote monitoring, reporting and control of underground injection water pressure at wellheads. The underground injection control (UIC) system handles all data monitoring, analysis, control and reporting necessary for compliance with California Code of Regulations Title 14 § 1724.10.4 and includes secure advanced process control capabilities for wellsite optimization.

“The state of California requires stringent monitoring of pressure being injected to aid water flood, and the deadline for such compliance has already passed. Non-compliant wells are subject to fines of up to $25,000 a day. In just days, we can set up a secure monitoring system via the cloud that eliminates risk of fines while improving pressure monitoring and reporting performance,” said Bedrock Automation founder, CEO and CTO Albert Rooyakkers.

The EPA has established underground pressure measurement requirements under Sections 1421, 1422 and 1425 of the Safe Drinking Water Act (SDWA). California has been among the most proactive in meeting those requirements. Unless producers can demonstrate adequate controls that prevent injection facilities from reaching established maximum allowable surface injection pressures (MASP), they must monitor and control injection pressure continuously and dynamically generate periodic reports to identify MASP events.

Open secure UIC

Bedrock’s turnkey UIC monitoring and reporting system enables midstream producers to accomplish the following:

System architecture

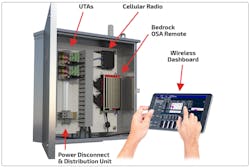

Bedrock UIC Pressure Monitoring and Reporting blends control and communications. The heart and brain of the system is the Bedrock OSA Remote control system. It receives pressure readings and other production data from up to 20 pressure sensing devices, processes related control logic and exchanges data with the cloud or SCADA system via MQTT or OPC UA. The system includes 64GB of secure onboard flash memory that will store injection data for many decades. And, like all Bedrock products, the OSA Remote is intrinsically cyber secure and made in the USA.

Complementing the OSA Remote are the following components:

- A cellular radio, which carries data signals from the OSA Remote to the cloud or SCADA application.

- Universal terminal assemblies (UTAs), which simplify access and termination.

- A power disconnect and distribution unit, which manages 24 V dc for safe and easy trouble shooting.

- An embedded SCADA dashboard for secure wireless visualization into the process.

The system runs on any 24 V dc power supply, including direct solar arrays but it can also be specified with a rugged Bedrock SPS.500 primary power supply and/or a UPS.500 uninterruptible power supply, which would provide enhanced availability, advanced diagnostics and Bedrock’s intrinsic cybersecurity.

The Bedrock UIC Pressure Monitoring and Reporting Solution is available for immediate implementation.