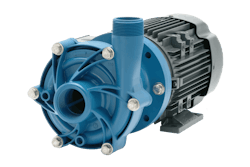

Sealless centrifugal pump

Finish Thompson Inc.’s DB10 sealless plastic centrifugal pump is ideal for transferring corrosive chemicals in water and wastewater treatment. With its unique, industry-leading five-year warranty, the DB10 pump offers the best efficiency of any pump in its class and can run dry for hours without damage, when equipped with a carbon bushing.

For water and wastewater treatment, the DB10 transfers chemicals from bulk storage to day tanks, unloads chemicals from tank trucks to bulk storage, provides flow of regeneration chemicals for ion exchange tanks and empties batch treatment tanks.

The DB10 is certified under CE (Conformité Européenne), UKCA (UK Conformity Assessment), and EAC (Eurasian Conformity). Also available are models that comply with ATEX (equipment for potentially explosive atmospheres) standards.

The DB10 pump is engineered for performance, with a close-coupled design, corrosion resistant polypropylene or polyvinylidene fluoride (PVDF) construction, and powerful neodymium magnets mounted to the motor shaft on every model. Featuring a sealless mag drive and a replaceable shaft and bushing, the pump mounts to NEMA and IEC motor frames, as well as motors without disassembly. The design eliminates the need for maintenance, flushing, or periodic seal replacement. The risk of leaks, vapor emission or exposure to corrosive chemicals is virtually eliminated.

The DB10 pump is equipped with 1.5-inch suction and discharge ports. It offers a maximum working pressure of 80 pounds per square inch (PSI)/5.5 bar, and a high maximum specific gravity of more than 1.8. Connection types, O-ring and bushing materials can be ordered to meet application-specific requirements.