Danfoss, HVAC industry mourn loss of respected colleague, innovator

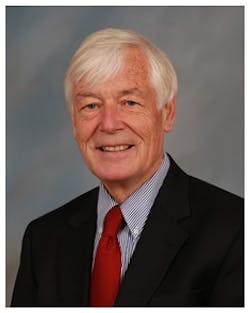

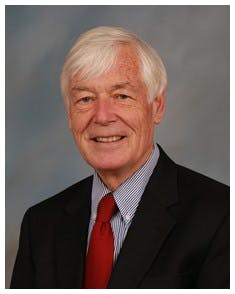

Sept. 22, 2015 -- On Wednesday, Sept. 2, the Heating, Ventilation and Air Conditioning (HVAC) industry lost a respected colleague, mentor and innovator -- Dr. Joost Brasz of Danfoss Turbocor Compressors, a manufacturer of valves and fluid-handling components for HVAC and industrial applications.

Brasz was recognized by the HVAC industry and the academic community as a leader and expert aerodynamic engineer in turbomachinery and centrifugal compressor technology. He was a frequent author and speaker at prestigious conferences, including the Purdue International Compressor Engineering Conference.

He received numerous patents in the field -- including for the newest Danfoss Turbocor compressor technology, the innovative VTT Series of Compressors with IntraFlow™ technology. He was a Ph.D. graduate of Eindhoven University of Technology in Eindhoven, Netherlands. Brasz leaves a tremendous legacy to Danfoss Turbocor Compressors and to the HVAC industry, having made his mark on innovation and the potential of energy efficiency.

See also: "Video - Danfoss: High pressure pumps for SWRO"

About Danfoss

Danfoss products and services are used in areas such as refrigeration, air conditioning, heating, motor control and mobile machinery. The company is also active in the field of renewable energy as well as district heating infrastructure for cities and urban communities. Its innovative engineering dates back to 1933 and today Danfoss employs 24,000 employees and serves customers in more than 100 countries. It is still privately held by the founding family. For more information, visit www.danfoss.com.

###