Keeping Chemicals in the Tank: Instrumentation, Monitoring and Control Solutions for Leaking of Overfilled Tanks

By Bill Sholette and Ricardo Chavez

Recent events in the state of West Virginia have shown that our water supply is in jeopardy of contamination from leaks or overfills of storage and processing tanks (see Fig. 1) at chemical, petroleum, water/wastewater, and similar facilities.

In January 2014, the city of Charleston was affected when a tank containing 4-methylcyclohexane methanol leaked, causing contamination of the Elk River, which provides over 300,000 people with drinking water. Residents were without tap water for at least five days. But it may be months or even years before the total effect of the spill is known.

The company that owned the storage facility where the leak occurred -- Freedom Industries -- is now facing at least 31 lawsuits, along with state and federal investigations. As a result, the company has filed for bankruptcy.

In the wake of the Elk River chemical spill, it is clear that chemical storage facilities will face additional scrutiny, along with careful reviews of existing regulations. However, with a few precautions and a relatively minor investment, this event could have been identified early on, and action could have been taken to mitigate the leak and its destructive consequences.

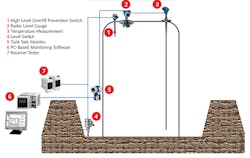

Instrumentation exists that can monitor the contents of a vessel and provide an alarm in the event of a leak or overfill event. These products have been used for years and are well-established and reliable. Figure 2 shows typical instrumentation for monitoring tank levels to prevent overfills and leaks. Each instrument has a specific function for containing the contents inside the tank:

1. High Level Overfill Prevention Switch. This switch is installed to indicate when the liquid in the tank reaches a dangerously high condition. It's often called a High-High (HH) level switch, as it is mounted above the high level switch used to indicate the normal stop-fill point of the tank. If the high level switch fails, the HH level switch activates to prevent the tank from overfilling. These switches typically include a way to function-test the switch to ensure its integrity. Because HH level switches are mounted above the normal maximum fill point, they can operate for years without ever "seeing" liquid in the tank. Because of this, the ability to test the switch on a periodic basis to verify its functionality is critical. In far too many tanks, the HH switch is the only protection against spills. This is unacceptable. Additional spill and overfill detection methods are needed.

2. Radar Level Gauge. A radar level gauge continuously monitors level in the tank. It is extremely important that the level gauge be very accurate to detect leaks, spillage or overfills. A high degree of accuracy is needed to provide an indication if the level decreases when the liquid in the tank is not actively being transferred or pumped out. If the level starts to decrease during inactivity, it would indicate a leak in the tank, and the monitoring system would then provide an alarm. Because of these operating parameters, accuracy needs to be measured in fractions of millimeters. Radar level gauges can provide accuracy of 0.5 millimeters -- a sufficient amount for detecting even minor leaks. The radar level gauge also acts as a backup to the HH level switch.

3. Temperature Sensor. It is important to measure temperature of the liquid in the tank to provide proper compensation. This is because the volume of most chemicals expands or contracts with changes in temperature. Without compensation, these changes in volume will appear similar to changes in level when, in fact, the actual contents of the tank have not changed. Temperature sensors with multiple measurement points and accuracy of ±0.1˚C are required for this application. 4. External Level Switch. This level switch is mounted inside the retention dike to indicate if a liquid is accumulating. The level switch needs to be able to detect any liquid that is present. Even rainwater accumulating after a storm should be detected, as it is necessary to remove this water to maintain the appropriate volume of the dike. Essentially, any accumulation of liquid within the dike -- water or chemical -- requires a response. As such, switches that will reliably indicate the presence of any liquid, such as tuning forks, are best suited for this application.

5. Tank Side Monitor. The tank side monitor performs corrected-volume calculations using the output from the temperature probe and the signal from the radar transmitter to determine the height of the material in the tank. It also provides intrinsically safe loop power to the level gauge and temperature transmitter, reads data from all connected devices and displays the values of each instrument.

6. PC-Based Monitoring Software. This is a typical PC-based HMI software package that displays the output of each tank in a tank farm as well as volume calculations (see Fig. 3). Such software packages are available from several suppliers. These software packages typically have built-in web server capability, so an operator or engineer can quickly and easily access tank information from any PC or handheld device via a browser.

The software also monitors tank level and can react to any level change. It should have a feature that allows an inactive tank to be "Locked Down." If the level in a locked-down tank drops, it would indicate a leak, and the software would produce an alarm. As with all alarms and events, this information can be relayed to users via an Ethernet link so that information registers on the appropriate device such as a PC, tablet or smartphone.

7. Receiver Tester. In relation to the High Level Overfill Prevention Switch, it is critical to test HH and external level switches to ensure they are functioning properly. Although many level switches have continuous self-checking to monitor their health, the receiver tester allows an operator to test the switch manually via a pushbutton. The tester can detect a short circuit, an interruption in the signal line to the measuring sensor, vibrator corrosion in the sensor, or a defect in the input circuit. As a backup to the main automation system, the tester also includes relays to provide an output to an alarm and/or a control function such as a diversion valve to prevent overfilling.

Conclusion

An instrumentation and monitoring system like the one discussed above detects spills and leaks at multiple levels -- with tank monitors, HMI software and receiver testers providing redundancy.

The events in Charleston make it clear that chemical storage tanks need to be secure and that spills and leaks must be prevented where possible. This should extend to any industry -- chemical, oil and gas, water and wastewater, foundries, and others -- storing chemicals that could contaminate water supplies.

In the petroleum industry, for example, the American Petroleum Institute (API) has recommended practices for preventing and responding to spills (API2350 recommended practices for aboveground storage tanks). In the chemical industry, most facilities that manufacture chemicals are required to have an SPCC (Spill Prevention Control and Countermeasure) plan in place.

Unfortunately, because the facility in West Virginia only stored chemicals and did not manufacture them, the site inspections and permits that are required for manufacturing facilities were not required. A lack of these requirements and the failure of the owners to provide proper level monitoring ultimately led to the incident, which was serious enough to bankrupt the company.

Proper instrumentation for monitoring storage vessels can prevent spills and identify leaks. When dealing with locations where these incidents cannot be prevented, however, it is critical that they are quickly identified and that a response plan is in place to mitigate damage and environmental impact. Outfitting tanks with overfill prevention switches and tank monitoring instruments will provide the security needed to prevent catastrophes.

About the Authors: Bill Sholette is the Level Products Business Manager for Endress+Hauser in the Northeast. He has been involved in level measurement for the past 33 years in virtually all aspects of process level measurement instrumentation. Sholette attended Villanova University and has certification in management and marketing.

Ricardo Chavez holds a BS in Chemical Engineering from the Monterrey Institute of Technology and Higher Education. He is the Solutions Business Manager for Endress+Hauser in the East Coast with almost 20 years of experience working in instrumentation, process control and data integration into PLC/SCADA systems.