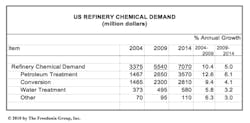

Demand for refinery chemicals to exceed $7B in 2014

May 5, 2010 -- US demand for refinery chemicals is forecast to expand 5.0 percent annually to $7.1 billion in 2014. Although refined products output is expected to decline through 2014, demand for refinery chemicals will be supported by the use of new, higher-value products which offer enhanced performance. Additionally, refiners will continue to subject their products to higher levels of chemical treatment in order to remove more impurities, thus supporting chemical demand in refinery applications. These and other trends are presented in Refining Chemicals, a new study from The Freedonia Group Inc., a Cleveland-based industry market research firm.

Market gains will primarily result from above-average increases in the large merchant hydrogen segment, due to rising use by refiners seeking to supplement their captive hydrogen production. Merchant hydrogen will remain the largest and fastest growing product in the US refinery chemical market. Environmental regulations limiting the sulfur content in fuels will continue to promote the use of hydrotreating -- the largest application for merchant hydrogen. Hydrocracking represents another growth application for merchant hydrogen.

Catalysts also account for a significant share of the market and are commonly used in the petroleum refining industry to improve energy efficiency and process productivity. Metal catalysts will maintain their position as the largest refinery catalyst type. Through 2014, these catalysts are expected to provide the fastest gains in the catalyst segment. Advances will be based on rising use in hydrotreating applications due to efforts to reduce sulfur content in refined products. Zeolites represent another leading type of catalyst used in the refining industry.

Among the variety of processes to refine crude oil are petroleum treatment, conversion and water treatment processes. Hydrotreating accounts for the majority of petroleum treatment chemical demand. This application, which primarily employs hydrogen and metal catalysts, will continue to expand based on its usefulness in removing contaminants from refined petroleum products. Among conversion processes, hydrocracking is expected to offer considerable growth potential. A major consumer of hydrogen, hydrocracking will benefit from its ability to boost production yields and increase refiner profitability. In water treatment processes, market value will expand due to a shift from commodity water treatment chemicals toward more expensive environmentally acceptable alternatives.

Refinery Chemicals (published 04/2010, 217 pages) is available for $4,700 from The Freedonia Group Inc., 767 Beta Drive, Cleveland, OH 44143-2326. For further details, please contact Corinne Gangloff by phone 440.684.9600, fax 440.646.0484 or e-mail [email protected]. Information may also be obtained through www.freedoniagroup.com.

###