Understanding calcium carbonate scale formation in water-cooled heat exchangers

Key Highlights

- CaCO3 scale formation is influenced by water chemistry, temperature, and geological factors, with limestone deposits being a primary source of calcium carbonate in surface waters.

- The solubility of calcium carbonate increases slightly in neutral water due to carbonate hydrolysis, but atmospheric CO2 absorption can alter pH and alkalinity, affecting scaling potential.

- Heating water reduces CaCO3 solubility, promoting scale formation, especially in heat exchangers, with evaporation in cooling towers further increasing dissolved solids and scaling risk.

- Traditional scale control methods included acid dosing and chromate treatment, but modern approaches now favor crystal modification and ion sequestration for environmental safety and efficiency.

Many heat exchangers at industrial facilities are water cooled. Without proper treatment, corrosion, microbiological fouling and scaling — singly or in combination — can cause serious difficulties. With regard to scaling potential, even seemingly pristine surface waters can conceal hidden dangers, including or often especially the potential for calcium carbonate (CaCO3) scaling. This article examines the fundamental chemistry of CaCO3 scale formation.

Geology and the atmosphere are primary influences on surface water chemistry

Reference 1 served as a primary source for the material in this section.

A common mineral deposit within the earth’s crust is limestone, whose principal component is CaCO3. This versatile mineral serves as a raw material for concrete, water treatment chemicals, scrubbing reagent and simply for gravel roads.

Many surface waters are in contact with limestone formations, and groundwaters often percolate into limestone deposits and then settle in aquifers that are bound by the mineral. Calcium carbonate has a strong crystal lattice, so CaCO3 is only slightly soluble in neutral water.

CaCO3 ⇌ Ca2+ + CO32- (1)

Ksp (25° C) = [Ca2+][CO32-] = 4.6 x 10-9

Per this solubility product, the molar concentrations of calcium and carbonate in neutral water would be 6.8 x 10-5 M, which is indeed slight. But an additional factor must be considered. CO32- is a fairly strong base and will hydrolyze water to some extent.

CO32- + H2O ⇌ HCO3- + OH- (2)

Combining equations 1 and 2 shows the overall reaction of CaCO3 in neutral water.

CaCO3 + H2O ⇌ Ca2+ + HCO3- + OH- (3)

Calculations indicate that CO32- hydrolysis of water shown in equation 2 increases the limestone solubility from 6.8 x 10-5 M to 9.9 x 10-5 M (at 25° C). An important point to keep in mind is that these reactions produce hydroxide alkalinity (OH-), even if only in small concentrations.

Carbon dioxide in the atmosphere influences surface water chemistry, and let’s now consider that effect.

Atmospheric influences

Natural waters absorb carbon dioxide from the atmosphere. While it is often argued that absorbed CO2 exists as hydrated molecules, the following equations accurately represent the chemistry:

CO2 + H2O ⇌ H2CO3 (4)

H2CO3 ⇌ H+ + HCO3- (5)

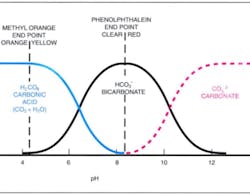

The lowest pH in natural surface waters that can be achieved by these reactions (without the influence of other ions) is around 5.6. Even though the CO2 influence is relatively minor, the acidity influence is very important. Consider again, Equation 3. When the acidity generated by CO2 absorption interacts with the alkalinity generated by the partial CaCO3 dissolution, the hydrogen and hydroxyl ions combine to form water, and per Le Chatelier’s Principle, reactions 3 and 5 are both driven to the right. This synergistic effect can produce water with a HCO3- concentration of 1 x 10-3 M (equivalent to about 60 parts-per-million as the species), and “a pH of about 8.3.” The relationship of the carbonate species is illustrated in the following chart.

At the two power plants and chemical plant where this author formerly worked, the freshwater makeup supplies (two lakes and an underground aquifer adjacent to a river) all had a consistent pH at or slightly above 8.0.

This same acid-base synergy is what makes high-purity limestone (high CaCO3 content) quite reactive and economical as a scrubbing agent, when ground to very fine particles, in wet flue gas desulfurization systems. Aqueous sulfur dioxide (SO2) is a stronger acid than CO2, and analytical data shows nearly complete CaCO3 reactivity in well-designed scrubbers.3

Bicarbonate cycle chemistry in reverse — the scaling mechanism

From the time humans began heating water for cooking and sanitary purposes, they have undoubtedly observed mineral deposition in heated vessels. These issues became acute following the invention and expanding use of steam engines during the Industrial Revolution of the 18th and 19th centuries. The primary culprit is calcium carbonate.

Ca2+ + 2HCO3- + heat → CaCO3↓ + CO2 + H2O (6)

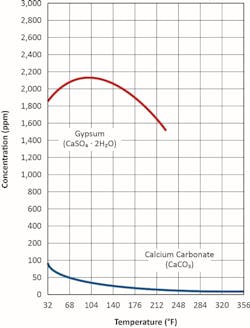

A key aspect of this chemistry is the inverse solubility of CaCO3, as illustrated below.

So, as water temperature increases during flow through a heat exchanger, and especially at the metal surface, the solubility limit of calcium carbonate may be exceeded. Even more important in many cases is the cycling in dissolved solids concentration that occurs in cooling towers from evaporation. The “cycling up” in concentration of calcium and bicarbonate alkalinity, and other dissolved elements and compounds, can push concentrations well past solubility limits.

Controlling CaCO3 deposition

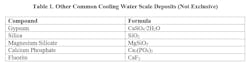

In the middle of the last century, a quite popular treatment program for open-recirculating systems was sulfuric acid feed for scale control (to establish a pH range of 6.5-7.0), with feed of disodium chromate (Na2Cr2O7) for corrosion control. Acid feed partially reversed the reactions shown in Equations 4 and 5, which kept the calcium/bicarbonate solubility product below saturation levels. However, in the 1980s growing recognition of hexavalent chromium (Cr6+) toxicity led to a ban on chromium discharge to the environment, which essentially eliminated chromate treatment for nearly all cooling water systems. Acid feed is still utilized at some plants to convert bicarbonate alkalinity to CO2, but many plant personnel have adopted modern chemistry techniques based on crystal modification and ion sequestration by specialty chemical feed. These programs also control other scale-formers, including those shown below.

The author is currently in the middle of a cooling water treatment series for Chemical Processing magazine (another EndeavorB2B brand), which goes into greater detail regarding scale, corrosion and microbiological cooling water control methods. Please refer to that publication for additional information.

References

1. C. Baird, Environmental Chemistry, Second Edition, W.H. Freeman and Company, New York, NY, 1999.

2. Post, R., Buecker, B., and Shulder, S., “Power Plant Cooling Water Fundamentals”; pre-workshop seminar for the 37th Annual Electric Utility Chemistry Workshop, June 6, 2017, Champaign, Illinois.

3. Buecker, B., “Wet Limestone FGD Solids Analysis by Thermogravimetry”; proceedings of the 24th Annual Electric Utility Chemistry Workshop, May 11-13, 2004, Champaign, Illinois.

About the Author

Brad Buecker

Brad Buecker currently serves as Senior Technical Consultant with SAMCO Technologies. He is also the owner of Buecker & Associates, LLC, which provides independent technical writing/marketing services. Buecker has many years of experience in or supporting the power industry, much of it in steam generation chemistry, water treatment, air quality control and results engineering positions with City Water, Light & Power (Springfield, Illinois) and Kansas City Power & Light Company's (now Evergy) La Cygne, Kansas, station. Additionally, his background includes 11 years with two engineering firms, Burns & McDonnell and Kiewit, and he spent two years as acting water/wastewater supervisor at a chemical plant. Buecker has a B.S. in chemistry from Iowa State University with additional course work in fluid mechanics, energy and materials balances, and advanced inorganic chemistry. He has authored or co-authored over 300 articles for various technical trade magazines, and he has written three books on power plant chemistry and air pollution control. He is a member of the ACS, AIChE, AIST, ASME, AWT, CTI, and he is active with Power-Gen International, the Electric Utility & Cogeneration Chemistry Workshop, and the International Water Conference. He can be reached at [email protected] and [email protected].