Solving halite problems in produced water

Water is arguably the planet’s most precious commodity. Without it, life would be non-sustainable and would cease to exist. It is vital to be frugal in the use of fresh water from any ecosystem, regardless of the seemingly unlimited quantities available.

In oil and gas operations, large volumes of fresh water are used in drilling, completion and process operations. These volumes of fresh water are continually being replaced with recycled brines, which were once pumped into disposal wells or conditioned and returned to potable water systems. Redeployment of water plays a significant part within a sustainable management scheme and, for most oil and gas operators, water reuse is a key metric. Yet, there are processes for which fresh water is still required. One of these processes is the prevention or remediation of halite (sodium chloride or NaCl) in gas production and refinement systems, which requires freshwater wash.

Halite typically forms in high-temperature and high-pressure gas fields. Changes in pressure and temperature conditions cause produced water evaporation into the gas or condensate phase, leaving the water stream in a supersaturated state. Supersaturation is what triggers the halite to precipitate, and since the solubility of halite in the water is high, it only takes a small increase in the saturation level for high volumes of halite to precipitate. Wet gas systems with low water content can also be sensitive to halite risk. In this case, where the hydrocarbon stream is almost dry, precipitated halite is found within oil-based mixtures consisting of paraffins and/or asphaltenes.

Common locations where halite may form are wells, bottom hole equipment, and surface facilities with emphasis given to separators and gas compressors, as well as reboilers where the high skin temperature of the equipment promotes the evaporation of any water present.

Halite can be a serious concern when not mitigated or remediated in a timely manner, resulting in:

- Plugging of valves, lines and equipment

- Under deposit corrosion

- Increased operating costs

- Loss of production and frequent system downtime

- Cleaning issues, which generate hazardous waste along with health, safety and environmental (HSE) concerns

Mitigation and Remediation

When it comes to onshore fields, halite deposits are historically treated with the addition of fresh water, which dilutes the brine to a level below the critical saturation level. This type of treatment eliminates the deposition problems downstream of the water injection but adds to flow assurance risks (e.g., corrosion issues, hydrates risk) and to operating costs. Deposits that have already occurred are removable by jet washing the system with fresh water, but often the damage has occurred beneath the deposits, requiring equipment to be replaced along with the extensive labor requirements. In addition, the wash water may become hazardous waste and must be added to the wastewater treatment process, driving up costs even higher.

Offshore, mitigation and remediation of halite is more difficult mainly due to seawater and produced water being the main sources available for water wash. Parameters, such as salinity, oxygen presence, etc., eliminate seawater from direct injection, hence pretreatment is necessary. The seawater treatment plant is designed to remove solids, oxygen and, in many cases, sulphates from the seawater prior to reservoir injection. Removing solids and sulphates prevents plugging and scaling in the production plant as well as within the reservoir itself. This plant is often one of the largest topsides modules in terms of space and weight, with the main treatment processes being membrane-based.

Produced water is treated to remove free oil prior to overboard discharge. For many years, produced water treatment has been based upon deoiling hydrocyclones followed by induced gas flotation. However, environmental legislation is driving a demand for treated produced water to be re-injected rather than disposed overboard. In this case, the main challenge is removing solids rather than oil.

Halite inhibitors are deployed by many operators for applications where halite risks need to be addressed. The chemistry of the inhibitor is designed to distort the nucleation and growth of the halite, resulting in dispersion and partially dissolving the already formed crystals. Effective halite inhibitors offer excellent halite control in gas wells and reduction in freshwater volume requirement. Eliminating the freshwater volume by using halite inhibitors can be highly beneficial for gas fields operating at conditions within the hydrates formation envelope. New generation halite inhibitors are highly biodegradable and are compatible with other chemicals, such as foamers, deployed in the field for gas well uploading.

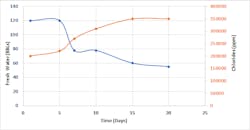

During application monitoring, key indicators, such as concentration of soluble chlorides and consumption of freshwater volume, is strongly suggested (see Fig. 1). These indicators are used for evaluation and further optimization of the inhibitor dosage. A robust collection and analysis of fluid samples at a frequency as agreed between the operator and the chemical vendor is also beneficial for monitoring the concentrations of ions in the water phase and the efficiency of the halite inhibitor.

Case Study

An international oil and gas operator, producing approximately 750,000 m3 per dayof wet gas from an onshore gas field, reported high scaling risk due to halite. The mitigation strategy initially considered by the operator was based on freshwater injection exclusively. This treatment approach was soon re-evaluated due to the high volumes of fresh water required and the frequent shutdown times for wash water operations. In addition, the remote location of the gas field required more demanding logistics.

Following the onsite survey, high volumes of deposits were recovered from the separators and the gas compressor. Deposits mainly consisted of halite and calcium carbonate, with the latter to a lesser extent. A mitigation strategy was put in place focusing on a chemical solution for scale mitigation and ultimately reducing the volume of fresh water required. A new chemistry was formulated targeting both halite and calcium carbonate inhibition and was tested in the field.

Onsite monitoring and frequent analysis of surface samples confirmed the reduction in the halite precipitation and increase of soluble chlorides in the produced stream. The deployment of the effective inhibitor successfully resulted in a significant reduction in the frequency of the freshwater washes from three days to a 90-day preventive shut down and water wash of the equipment (see Fig. 2). The overall cost savings for this application was more than $100,000 per year.

Following the successful field trial, the SUEZ halite inhibitor was adopted and is currently injected in several fields, allowing control of both halite and calcium carbonate scale types. For fields where calcium concentration was recorded at high levels, an increase in the halite inhibitor dosage was adequate to achieve full scale control with no compatibility issues.

Conclusions

Dealing with halite mitigation in gas fields, either onshore or offshore, requires a more sustainable treatment strategy. This is what upgraded halite inhibitors can offer nowadays. These highly biodegradable chemistries can eliminate scale risk and reduce operational costs associated with water washes. Yet, a thorough understanding of the process and production conditions, as well as good assessment of the water quality and water volumes already available onsite, are necessary prior to deploying a halite inhibitor in the field. It is only then that the mitigation strategy can be effective, offering optimization of water usage while maximizing gas production. WT

About the authors: Eleftheria Mavredaki is a product applications specialist at SUEZ – Water Technologies & Solutions. With 12 years of international experience in onshore and offshore operations, her expertise lies in flow assurance and produced water treatment. She holds a Ph. D in mechanical engineering and a bachelor’s degree in chemistry.

Sam Toscano is a senior global product manager for Energy & Chemicals Solutions. Toscano has more than 40 years’ experience in the oil and gas upstream chemicals industry. He holds a bachelor’s degree in chemistry from St. Louis University and an MBA in marketing/finance from St. Thomas University in Houston, Texas.

Graeme Orr is a global offshore sales manager for SUEZ Oil & Gas. With more than 30 years of experience in sales of high value equipment and services, 12 years of which were focused exclusively on offshore water treatment systems, Orr has a thorough understanding of the processes and drivers that influence the market. Being based in the United Kingdom and travelling around the oil regions of the world have given Orr a fascination for different cultures and business practices, as well as for emerging technologies and new developments in the offshore business.

About the Author

Eleftheria Mavredaki

Eleftheria Mavredaki is a product applications specialist at SUEZ – Water Technologies & Solutions. With 12 years of international experience in onshore and offshore operations, her expertise lies in flow assurance and produced water treatment. She holds a Ph. D in mechanical engineering and a bachelor’s degree in chemistry.

Sam Toscano

Sam Toscano is a senior global product manager for Energy & Chemicals Solutions. Toscano has more than 40 years’ experience in the oil and gas upstream chemicals industry. He holds a bachelor’s degree in chemistry from St. Louis University and an MBA in marketing/finance from St. Thomas University in Houston, Texas.

Graeme Orr

Graeme Orr is a global offshore sales manager for SUEZ Oil & Gas. With more than 30 years of experience in sales of high value equipment and services, 12 years of which were focused exclusively on offshore water treatment systems, Orr has a thorough understanding of the processes and drivers that influence the market. Being based in the United Kingdom and travelling around the oil regions of the world have given Orr a fascination for different cultures and business practices, as well as for emerging technologies and new developments in the offshore business.