Breaking the barrier: Advancing heat transfer efficiency through dropwise condensation

Key Highlights

- Dropwise condensation significantly improves heat transfer efficiency by preventing the formation of insulating water films on condenser surfaces.

- Adopting dropwise condensation helps industries meet sustainability goals by lowering fuel use and CO2 emissions, while also enhancing equipment durability and operational stability.

- Compared to filmwise condensation, dropwise offers a higher heat flux, especially when using copper alloys, making it ideal for harsh industrial environments.

- The shift to dropwise condensation is a strategic move for industries seeking to optimize performance, reduce costs, and align with evolving environmental regulations.

Dropwise condensation

Throughout the refining and petrochemical industries, steam is critical for maintaining production goals. Due to tightening regulations, many corporations are now integrating sustainability goals into their corporate social relationships, requiring plants to use steam more efficiently and reduce fuel consumption. There are also incentives for some industries to acquire carbon dioxide (CO2) credits from government programs.

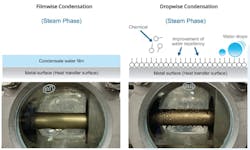

While filmwise condensation has long been the standard in industrial steam systems, its inherent thermal resistance limits heat transfer efficiency. In contrast, dropwise condensation — enabled by advanced surface treatments — offers significantly improved heat transfer performance, helping facilities reduce energy consumption and meet sustainability goals.

Traditionally, industrial facilities with steam turbines have surface condensers that operate with a natural filmwise-type of cooling in their surface condensers. This film spreads out and covers all surfaces, creating a consistent layer of condensate. This creates a barrier to the most efficient condensation of steam. Depending on the process and the equipment design, filmwise condensation can cause enough of a thermal barrier to reduce heat transfer that affects production or energy efficiency, particularly when water-side impairments are introduced. This could be due to flow restrictions on the cooling water or high bulk water temperature during summer months.

However, in the last 50 years or so, there has been a move toward developing ways to create conditions for dropwise condensation, which is the formation of distinct droplets. These droplets then roll off the surface, exposing fresh areas for condensation. This process minimizes thermal resistance by not creating an insulating layer. Until recently, the creation of dropwise condensation was done by adding films or coatings of some kind to the steam side of the surface condenser tubes. While this was an interesting concept, the results have not always been as good as desired.

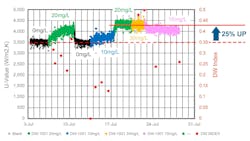

Dropwise condensation will help improve heat transfer efficiency, reduce steam consumption, maintain production goals and help maintain a stable operation when maximizing production. Dropwise condensation can be achieved through steam treatment technologies that help facilities increase productivity and reliability while reducing energy consumption. Compared to traditional techniques, dropwise condensation allows for a significantly greater heat transfer coefficient because of its distinct droplet formation as the surface remains unwetted. The amount of increase in the heat transfer coefficient will also be affected by the metallurgy of the heat exchanger. Copper alloys perform much better compared to stainless steel and titanium.

Both dropwise and filmwise condensation modes are seen in industrial processes, and depending on the objective of the steam use, each could be useful. However, one must consider the implications for their heat transfer efficiency on surface condensers. Dropwise conditions can help facilities maintain or minimize heat transfer decreases, increasing costs and the accumulated energy use.

The primary purpose of the dropwise technology was to enhance heat transfer, helping specific industries and processes operating in harsher environments. Along with the operational and economic benefits for a facility are the environmental benefits. These benefits provide the following operational synergies. What improved heat transfer efficiency means:

- Improved heat transfer in cooling can help maintain a stable operating condition, particularly when operating at maximum production rates.

- A coating that offers protection can reduce the need for other chemical treatments, such as corrosion inhibitors, offering a higher level of safety at a facility and possible discharge into the environment.

- Reduced fuel consumption because of improved heat transfer efficiencies will reduce CO2 emissions.

Ultimately, the dropwise technology protects both industrial equipment by enhancing durability, efficiency and performance while helping to reduce greenhouse gas emissions.

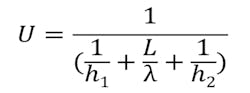

Filmwise is when fresh steam condenses on the surface condenser tubes outside of the film and heat is transferred by convection, instead of conduction, through the film to the metal surface. This heat flows through the film, and like all energy exchanges, it is associated with heat loss.

This film of water acts as a heat transfer barrier, and its resistance to heat transfer accounts for the difference between the effectiveness of filmwise and dropwise condensation. Due to the nature of the materials used in the construction of condensing heat exchangers, filmwise condensation is normal.

The next generation of heat condensation treatment is Kurita Dropwise Condensation Technology, which prevents the water film and enables more efficient heat transfer with steam. As the steam condenses, many spherical water beads cover the surface. Then, as the condensation proceeds, the beads become larger, coalesce and fall over the surface. The dry surface offers very little resistance to heat transfer and much higher heat fluxes are possible.

Specifically, by continuously injecting Kurita Dropwise Condensation Technology into the steam line and forming a water-repellent film on the heat transfer surface (i.e., steam condensation surface), Kurita Dropwise Condensation Technology continuously prevents this water film and the heat transfer coefficient is improved. This makes it possible to improve the overall heat transfer coefficient in heat exchangers. The overall heat transfer coefficient is influenced by the thickness and thermal conductivity of the materials through which heat is transferred. The larger the coefficient, the more efficiently heat is transferred from its source to the product being heated.

Dropwise condensation offers improved steam quality in industrial facilities, especially in refining and petrochemical plants. The next generation of condensation technique is Kurita Dropwise Condensation Technology, a chemical injection into the steam line between the steam turbine and surface condenser, which resolves the insulating layer of condensate film in steam heating and enables more efficient heat transfer. This improves the steam side film heat transfer coefficient and results in an increased overall heat transfer.

A facility’s steam production may not necessarily be reduced, but consumed in a more efficient way, allowing for plants to increase productivity and maintain stable operations during periods of high bulk cooling water temperatures. Along with those benefits, plants can reduce their fuel consumption and decrease the amount of CO2 generated to help meet operational and corporate sustainability goals.

In the evolving landscape of industrial steam systems, the shift from filmwise to dropwise condensation marks a pivotal advancement in heat transfer technology. While filmwise condensation has served as the conventional method, its inherent thermal resistance limits efficiency and increases energy consumption. By contrast, dropwise condensation — and the associated technology — offers a transformative approach, enhancing heat transfer, reducing fuel usage and supporting stable operations even under challenging conditions.

As industries strive to meet both production and sustainability goals, embracing technologies that enable dropwise condensation is not just a technical upgrade but a strategic imperative. The future of industrial efficiency lies in surfaces that shed barriers, not just water.

About the Author