In the summer of 2011, the Lincoln Avenue Water Company (LAWC) in Altadena, Calif. was confronted with a significant increase in the cost of virgin activated carbon, the plant’s primary groundwater treatment media. Two years later — after thorough pre-testing and a graduated switch to reactivated carbon — LAWC has cut its activated carbon costs by 20 percent without any sacrifice in water quality.

From ranches to missile ranges

Located in the foothills near Pasadena, LAWC has been in operation since the late 1890s with primary origins as an irrigation cooperative for local citrus groves and ranches. In the early 1900s, when the area’s population started to boom, LAWC began to take on the functions of a traditional water utility to meet the demands of a growing community. The company drilled its first groundwater well in 1913. By the 1970s, LAWC was drawing water from two active wells while operating 11 reservoirs.

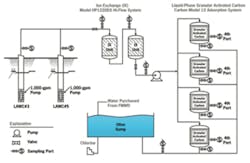

In 1984, testing discovered harmful contaminants in the groundwater, largely due to the plant’s proximity to the Jet Propulsion Laboratory (JPL) and the active wells were shut down. Eight years later, LAWC installed a liquid–phase granular activated carbon (GAC) adsorption system to treat the contaminated groundwater. In 2004, an ion-exchange system was added to the treatment process to combat high concentrations of perchlorate. The Los Angeles County system was the first to be approved by the California State Department of Public Health.

Current plant and contaminant profile

Today, LAWC supplies water to 16,000 residents of West Altadena through 4,500 service connections. The plant has an operational capacity of 5.18 million gallons per day (mgd). In addition to groundwater drawn from two deep-water wells in the Raymond Basin, which are its primary sources of water, LAWC operates a surface water treatment plant and imports water from the Foothill Municipal Water District, a member agency of the Metropolitan Water District.

Well water contaminants include trichloroethylene (TCE), carbon tetrachloride (CTC) and tetrachloroethylene (PCE), along with the aforementioned perchlorate. They are residual volatile organic compounds (VOCs) from seepage pits that were used by JPL to dispose of chemical waste during missile testing in the 1940s and 1950s. The pits were replaced by a sewer system in the late 1950s, but it was too late to prevent contamination by the remnant chemicals.

LAWC’s treatment operation is funded by NASA with regulatory oversight by the California Department of Public Health, California Regional Water Quality Control Board and the federal Environmental Protection Agency (EPA).

As Figure 1 demonstrates, accelerated column tests (ACT) revealed the following:

- The custom municipal reactivated (CMR) onion-like carbon (OLC) outperformed the incumbent OLC for removal of total organic carbons (TOC) with both OLCs demonstrating saturation and “rollover” TOC effluent concentrations after treatment of 40 million and 50 million gallons of water. It was predicted that the superior performance of the CMR OLC is because reactivation tends to generate additional pores in the carbon for TOC adsorption.

- After simulated treatment of 120 million gallons of water (165 days of simulated operation), neither OLC exhibited a confirmed breakthrough of any VOC at or above the method detection limit (MDL). ACT data detected no difference in VOC removal between the CMR and virgin OLC.

- For both OLCs, ACT predicted service lives that were significantly longer than the average service life at LAWC. Lower–than–average TOC and VOC concentrations in the feed–water used for ACT may have accounted for the extended service performance estimate.

The second testing protocol was the WaterAds Adsorption Model. This assessment tool uses TACTIC computer modeling to identify the “fingerprint” or “adsorption curve” for single carbons in tandem with Polyani adsorption theory to calculate loading and use rates based on pre-stated contaminant concentrations.

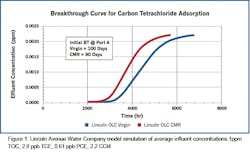

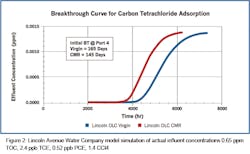

As Figures 2 and 3 demonstrate, WaterAds modeling revealed the following:

- The predicted service life for CMR and virgin OLCs treating inlet water with “average” VOC concentrations tracked very closely to the actual service life reported by LAWC. The virgin OLC lasted about 100 days before initial breakthrough of CTC in the presence of 1 part per million (ppm) background TOC. Under identical conditions, WaterAds modeling predicted CTC breakthrough for CMR OLC at approximately 90 days, which made its performance roughly 90 percent equivalent to virgin OLC.

- With inlet VOC concentrations from “actual” ACT feed- water samples, WaterAds modeling predicted CTC breakthrough at 165 days for virgin OLC and 145 days for CMR OLC, again approximating 90 percent virgin carbon performance.

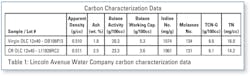

Figures 2 and 3 show the predicted performance of the CMR and virgin OLCs according to “average” and “actual” influent contaminant concentrations found in the LAWC feed-water. The contaminant profiles are listed in the table below:

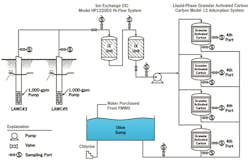

Custom React TACTIC Comparison (CRTC)

For the third procedure, the team employed CRTC testing, which is similar to WaterAds modeling because of its use of TACTIC adsorption profiles for single carbons. Using this method, they classified influent VOC concentrations from LAWC groundwater according to the two general application profiles highlighted in Figure 4. It then compared the test results for the CMR and virgin OLCs specifically formulated for LAWC.

As with WaterAds modeling, it was determined that the CMR OLC would perform 90.1 to 98.6 percent as effectively as the virgin OLC, depending on which of the two contaminant profiles was used.

Based on the WaterAds modeling and CRTC testing, the team recommended that LAWC install a coconut–based, 12×40 CMR OLC with 20 percent virgin make–up to achieve at least 90 percent relative performance to virgin OLC.

From the lab to the field

Based on test results from ACT, WaterAds modeling and CRTC testing, the facility’s veteran general manager Bob Hayward approved the conversion of LAWC’s first GAC adsorber from virgin OLC to CMR OLC in early 2012. As proposed, the CMR OLC is a coconut–based 12×40 mesh with a maximum virgin OLC make–up of 20 percent. All OLC used at the plant is sequestered and reactivated.

Nearly two years into the change-over, Hayward and his assistant, Jennifer Betancourt, LAWC’s water quality control coordinator, have continually monitored system performance. She reports that, so far, the results have been even better than expected.

“We’ve experienced about a zero percent drop in the cost-per-change-out and there has been absolutely no change in the quality of our water,” Betancourt explains.

“Overall, we are very pleased with everything,” she adds. “The plant is meeting all the goals established by the company and we’re providing our customers with safe, reliable drinking water at the most economically feasible cost. The treatment facility allows us to produce our own local water and defer the purchase of expensive imported water.”

Groundwater treatment system profile

Groundwater at LAWC is treated with four 20,000 pound GAC adsorbers that run in parallel to provide a total treatment capacity of 3,600 gallons per minute (gpm). Influent flow control valves ensure equal flow to each vessel. The parallel systems are monitored for TCE, CTC and PCE at the fourth-side sample port of each adsorber vessel, which represents about 75 percent (or about 15,000 pounds) of the stored GAC. Empty bed contact time (EBCT) is seven minutes. The presence of any of the aforementioned VOCs in the fourth side sample port triggers a change-out, which ensures that the final effluent water remains in compliance.

When LAWC was first approached about converting to a custom municipal reactivated carbon, Hayward?was skeptical about its potential performance. While he was willing to adopt leading-edge treatment methods?to promote greater sustainability at LAWC, Hayward wanted reliable evidence that the proposed formulation would work effectively before he consented to a real-time trial. He also wanted a reasonable guarantee of performance if LAWC ultimately agreed to make the switch permanent.

Measures were taken to satisfy Hayward’s concerns. The result was a mutually developed and approved comprehensive testing, trial and implementation program to predict the performance of the proposed reactivated carbon and to verify that it would, at the very least, maintain the performance standard established by the incumbent OLC.

In August 2011, three separate testing protocols were initiated to demonstrate the viability of the proposed carbon:

- Using feed-water collected from LAWC, two parallel ACTs were run at its Pittsburgh laboratory, one with the virgin OLC and the other with 100 percent CMR OLC. Each ACT simulated 15,000 pounds of carbon at seven minutes EBCT to mimic the actual LAWC operation.

- In addition, because pre-testing of the LAWC groundwater samples revealed less-than-expected levels of VOCs, they were spiked with higher concentrations of TCE, CTC and PCE before the trials began.

- The duration of the ACT simulated nearly six months of operation, which was almost twice the expected life of a single in-service adsorption vessel equipped with virgin OLC at LAWC.

Reactivation is not only a cost effective process, it’s also a successful way to become environmentally conscious. With reactivation, the CO2 footprint associated with reactivation is significantly lower than that associated with the production, supply and use of virgin activated carbon. LAWC and utilities across the globe have started to realize the true value and potential in reactivation and that making the switch can be an effective, long-term option.

Leo Zappa manages Calgon Carbon’s municipal drinking water business segment. Leo has worked for Calgon Carbon Corporation for more than 20 years, holding positions in sales management, product management, marketing and project management. Leo holds an Associate Degree in architectural engineering from the Pennsylvania State University, a Bachelor of Science in civil engineering technology from the Pennsylvania State University and earned a Master of Business Administration from Robert Morris University. Leo is also a graduate of the United States Army combat engineer school (Ft. Belvoir, Va.).