Chemical companies often use up to 3 pounds of water for every pound of chemical they produce, making them some of the biggest water users on the planet. However, quantity is not all that matters — the quality of the water used has a direct correlation to the efficiency of the plant. All the water used must first be cleaned to remove organic impurities, manage micro-bio organisms, and prevent scaling, corrosion and foulants from hindering efficiency and damaging the plant’s pumping infrastructure. These treatment processes typically involve metering large doses of sulfuric acid, sodium hypochlorite, phosphoric acid and various amine (scrubbing) solutions to remove organic impurities.

About 70 percent of the water used by a chemical company will be discarded after it is used just one time. When a given process is finished, the used water can become toxic, so it must be treated before it can be properly disposed of. These processes include disinfection, dechlorination, and odor and color control.

The alkalinity of the process water must be restored by injecting harsh chemicals such as sulfuric or hydrochloric acids to correct pH levels. Disinfectants like chlorine or sodium hypochlorite are also used to improve odor and kill unwanted microorganisms.

Treating wastewater before disposal is not just a process requirement — it is a critical part of a company’s brand because chemical companies want to be good neighbors in their communities. In many cases, they are required to be good stewards of the environment.

The requirements for these water treatment applications typically feature exceedingly high flow volumes and uniform, pulse-free dosing under low pressures, with accuracy requirements down to 2 or 3 percent. For these reasons, rotary gear pumps are ideal.

In addition to high-flow and low-pressure requirements, rotary pumps are well-suited for water treatment applications for many other reasons. They are less sensitive to changes in liquid viscosity. They do not require ancillary components, such as pulsation dampeners or pressurized supply tanks, for liquids that do not flow freely. Rotary pumps also provide other advantages.

Enhanced safety

Because exposure to some chemicals, such as chlorine gas, can cause respiratory issues for personnel, great care should always be taken to ensure that leaks do not occur when dosing hazardous chemicals. Sealless gear pumps offer fewer points of failure because they have no leak points for harsh chemicals to damage the pump or the surrounding equipment. Sealless rotary gear pumps also offer a higher level of safety for end users working with water treatment applications.

Reduced maintenance costs

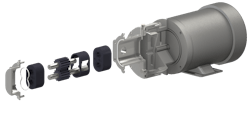

Maintenance savings start with a simple design. If a pump’s gears are not readily accessible, then engineers must decouple the motor, close the valves, and remove the piping at the suction and discharge ports of the pump. Rotary gear pumps feature a front pull-out design that is easy to access, so they can be repaired in place (see Image 1). This minimizes downtime by eliminating the need to lock out/tag out the pump and move it to the repair shop (which, in most chemical plants, would need to be carried out by a separate union employee).

Image 1. Replacement parts for this rotary pump only fit in one way, ensuring quick and mistake-free replacement.

Maintenance is also streamlined by using pumps that require fewer parts. Some pump models feature more than 40 parts, while rotary pumps have less than 20. As a result, the maintenance team has an easier time stocking and ordering kits that include all the required gears, bearings, O-rings and liners. Some rotary pumps also feature symmetrical parts that only fit one way, ensuring quick and mistake-proof replacements.

Increased chemical plant uptime

Maintenance costs for a single repair will always be insignificant compared to the costs associated with lost production and process restarts. The true return on investment (ROI) for maintenance is always connected to a plant’s uptime — particularly for chemical plants that operate continuously. By using rotary gear pumps, plant operators gain the flexibility needed to schedule maintenance between shifts or during the most opportunistic times.

The front pull-out design of a gear pump is also a significant factor for original equipment manufacturers (OEMs), who build skids and complete solutions for similar types of customers. In many cases, a client’s business model focuses less on the pumps, tanks and piping infrastructure and more on the margins that come from high-volume sales of the chemicals that these plants use on a daily basis. OEMs do not want to worry about maintenance issues or complicated pump repairs that hinder plant uptime. Rotary pumps with a front pull-out design are easy to access and repair in place. This streamlined maintenance minimizes repairs, maximizing plant uptime, which keeps everyone happy.

Considering all the costs

At first glance, the equipment and maintenance savings derived from using rotary pumps for water treatment applications might seem minimal (measured in tens of thousands of dollars). However, they play a key role in helping chemical manufacturers achieve the greater goal of managing their water envelope globally.

From a financial perspective, chemical companies invest tens of millions to hundreds of millions of dollars annually for water acquisition, treatment and disposal. The management of water and the infrastructure needed to treat it are critical. Savings of only 1 to 2 percent in this area can substantially impact a chemical producer’s bottom line.

By adopting a more efficient chemical feed process to treat wastewater and by using pumps that require less maintenance, chemical manufacturers, particularly in the Southeastern U.S., bolster their productivity through increased uptime and avoid costly accidents, complying with U.S. Environmental Protection Agency regulations, avoiding potential fines and minimizing the disruption that might accompany audits. They are also better environmental stewards and neighbors in their communities.

Karen Eisemann has a Master of Science degree in applied math and statistics from Rochester Institute of Technology. She spent decades working in capital equipment industries and is presently the director of customer service/rotary product manager for Pulsafeeder Engineered Products. She may be reached at [email protected].

Founded in 1946, Voigt-Abernathy is a distributor of rotating and process equipment for industrial markets. It provides engineering and design services to optimize equipment selection and aftermarket services to keep equipment functioning for chemical manufacturers.

For more information on the rotary pumps discussed in this article, visit pulsa.com/eclipse. For more information on Voigt-Abernathy, visit voigtab.com/about-us.