Often "more" is thought of as "better," but usually that is not reality. Think of the potentially detrimental effects of having more food, too much information or even too many choices. Similarly, "more" is not necessarily beneficial in an industrial setting. Consider zero liquid discharge (ZLD) systems, which strive to completely eliminate industrial liquid discharge.

For years, ZLD has been touted as an environmentally friendly way to help industrial and municipal water users meet increasingly strict use and discharge requirements and recycle their produced wastewater. However, ZLD processes are also technically daunting, highly expensive and not necessarily environmentally friendly due to the additional material, energy and disposal resources that ZLD typically requires.

Instead, industrial and municipal users are increasingly adopting a minimal liquid discharge (MLD) approach: a core set of proven filtration-based technologies and processes that enable users to achieve up to 95 percent liquid discharge recovery at a fraction of ZLD’s costs. In this article, we explore the components and potential benefits of MLD for industrial and municipal users seeking cost-effective, sustainable solutions to help improve their water footprint.

Why MLD?

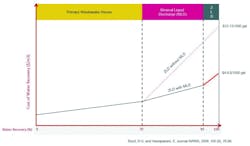

Figure 1. Cost comparison of MLD versus ZLD

As the term implies, minimal liquid discharge can help municipal and industrial plants make solid, substantial gains in minimizing liquid discharge. MLD also can help plants significantly minimize their capital and operating costs, since attaining the final 3 to 5 percent of liquid elimination to achieve ZLD can prove outrageously costly, according to industry experts (see Figure 1).

In theory, ZLD sounds promising, and in water-starved or environmentally sensitive regions of the world, ZLD may be useful. However, the greatest challenges to ZLD are economic. ZLD systems require significantly higher capital and operating expenditures and greater technical challenges than alternative options. According to industry experts, taking the last few steps needed to achieve complete ZLD status can nearly double a user’s costs.

Because recovery costs with ZLD are so high, it will remain applicable to only a limited group of manufacturing sites. In contrast, the MLD approach offers a great opportunity to achieve substantial gains. When facing significant discharge mitigation costs, end users often ask, "What are my other options?" MLD is a great option.

While the term MLD might be new, the processes on which it is based, using primary and secondary reverse osmosis (RO) systems and nanofiltration, relies on proven, existing technologies — with a host of additional tweaks and improvements. MLD is definitely not a new concept because it uses RO and NF to substantially and sustainably improve discharge. It is more a matter of adopting the mindset that facilities can achieve significant gains without breaking the bank.

For example, an excellent example of an MLD mindset in action was implemented at the General Motors (GM) vehicle assembly plant in San Luis Potosi, Mexico (about 400 km northwest of Mexico City), which opened in 2008. The plant has an annual capacity of 160,000 cars and is located in an arid, remote area with no receiving stream or municipal sewer available to discharge wastewater. Yet by using a combination of RO technology, a proprietary high-rate chemical softening process and other technologies, the plant can convert up to 90 percent of its tertiary wastewater into reusable water, leaving less than 10 percent of the liquid as waste for discharge into adjacent solar ponds

for evaporation.1

GM determined that 90 percent was the optimal economic number for its wastewater conversion, which is what MLD is all about — providing users with a spectrum of options to achieve the results most optimal for a specific plant. For some, it could be 90 percent. For others, it could be 80 or even 70 percent.

Diversity of dischargers

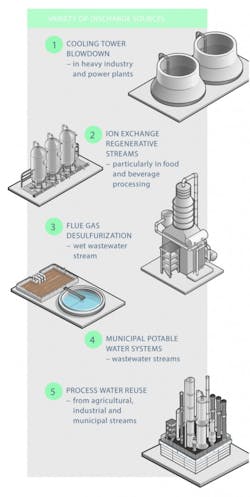

The sheer diversity of discharge streams across industries, markets and municipalities calls for minimum liquid discharge solutions tailored to individual needs. Potential discharge sources (see Figure 2) — and opportunities for MLD-driven improvement — include:

Figure 2. Different discharge sources

- Cooling tower blowdown — in heavy industry and power plants

- Ion exchange regenerative streams — particularly in food and beverage processing

- Flue gas desulfurization — wet wastewater stream

- Municipal potable water systems — wastewater streams

- Process water reuse — from agricultural, industrial and

municipal streams - Various industrial wastewater streams — from the textile, coal-to-chemical, food and dairy or battery industries

In general, all these discharge sources can be broken into one of two main themes: volume streams and complexity streams. A tailored approach for MLD depends on whether a volume stream, a complex stream, or some kind of combination must be treated and the location. New MLD-related technologies are enhancing these efforts.

For example, for municipal desalination plants, getting a 93 percent recovery is possible using primarily a traditional dual-membrane treatment system, chemical adjustments and precipitation. It is typically a combination of brackish water RO, nanofiltration and seawater RO.

The question then becomes what to do with the remaining concentrate. For many desalination plants, the preferred disposal method is discharge into the ocean, if practical and allowed. If ocean disposal is not an option, alternatives vary by location. In the U.S., which primarily has small-scale desalination plants, the primary locales for concentrate disposal are evaporation ponds and injection wells. However, in much of Asia, given its population densities and environmental factors, surface- or injection-based concentrate disposal options are not viable.

In such instances, an RO system is typically used to pre-concentrate the brine. Newer technology enhancements for this process include the spiral wound ultra-high pressure RO (UHPRO), which allows operation up to 1,740 psi (120 bar). The high operating pressure can achieve brine concentrations between 100 and 200 g/L of total salt concentration thus concentrating the brine from an upstream seawater RO two to threefold. This intermediate concentration step not only requires less energy than thermal evaporation, but also reduces the size of these highly expensive systems by 30 to 60 percent.

Another technology variant, which can replace evaporative systems, is forward osmosis. Like RO, it uses a water-permeable, salt-rejecting membrane to separate water from dissolved solutes. The driving force for this separation is an osmotic pressure gradient so that a draw solution of high concentration (relative to that of the process feed solution) is used to induce a net flow of water through the membrane and into the draw solution. This process is less prone to fouling and scaling and, depending on the type of draw solution, helps eliminate the need and use of high-pressure pumps.

China, because of its acute water and water quality needs, is interested in adding newer technologies and approaches, such as ultra high-pressure RO and forward osmosis, to its water treatment protocols. China has been on the leading edge of new technologies in water treatment.

Reduced costs & environmental impact

Perhaps the most compelling rationale for pursuing a minimum liquid discharge approach is how it helps reduce capital and operating costs, when compared with ZLD. The costs of membrane-based pretreatment and filtration technologies applied in MLD are relatively minimal compared to the exponentially greater capital and operating costs of ZLD-related evaporators and crystallizers.

The advent of new technologies, such as ultra-high pressure RO and forward osmosis, is important to end users. Newer technologies can extend recovery and minimize, or perhaps even eliminate, the size or need for evaporators and crystallizers. At the very least, users should investigate these options when planning their discharge mitigation strategies. Waste heat can often be used from some of these operations to provide additional cost-saving and efficiency benefits to an MLD approach.

Evaluating minimal liquid discharge needs

What is the best way to determine if a plant is a candidate for minimal liquid discharge? Often, the first step is to understand the driver for brine or wastewater treatment: Is it to reuse water, to meet local regulations or both? If it is "simply" water reuse, MLD is most likely indicated. If it is to meet local regulations, MLD would be part of the solution, which also might include ZLD, evaporation ponds or injection. The next step would be to conduct a water audit to identify the sources and types of wastewater generated in a facility, especially in terms of flow and total dissolved solids content. Not all wastewater is equal in type or treatment required. By matching waste streams and appropriate water requirements, facility and operations managers can better identify how much wastewater (if any) requires processing and the approach that will most economically and sustainably match the plant’s needs.

For example, some wastewater sources, such as condensate and stormwater, require minimal cleaning. Other sources, such as those with high concentrations of organic compounds, salts, metals and suspended solids, likely require more rigorous treatment. Similarly, consider the application of the treated water. For instance, cooling water and process water do not need to be treated to the same standards as potable water.

Based on the results of a water audit, and in consultation with a qualified wastewater treatment professional, consider exploring the following next steps to determine the suitability of adopting an MLD approach:

- Maximizing water recovery — from RO-based systems

- Purifying water — to sufficient standards for discharge and/or injection

- MLD — ensure all opportunities for water recycling have

been exhausted

The most important factor to remember is that a minimum liquid discharge approach enables a plant to address the substantial "limbo" that exists between minimizing discharge and go-for-broke ZLD. Remember it is not necessarily an all-or-nothing proposition — especially when the costs of all appear prohibitively expensive.

Depending on your facility’s regulatory and environmental needs and requirements, as well as your capital and operating budget, MLD can be a good fit for a wide range of industrial and municipal sites seeking to more cost-effectively improve their

water footprint.

MLD benefits in food plants

References

Andreas Gorenflo is the business development leader and strategic marketing manager for mining for RO at Dow Water & Process Solutions. He brings more than 20 years of experience in RO, NF and UF with a focus on desalination and wastewater. In this role, he is in charge of Specialty Membranes, which covers a range of existing and new applications and products for various industries, such as mining, chemical, and food and beverage industries.